Steel cylinder for quickly adding refrigerant

A refrigerant and steel cylinder technology, applied in the field of pressure vessels, can solve the problems of complex operation, refrigerant cylinder explosion, and low efficiency improvement, and achieve the effects of convenient use, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

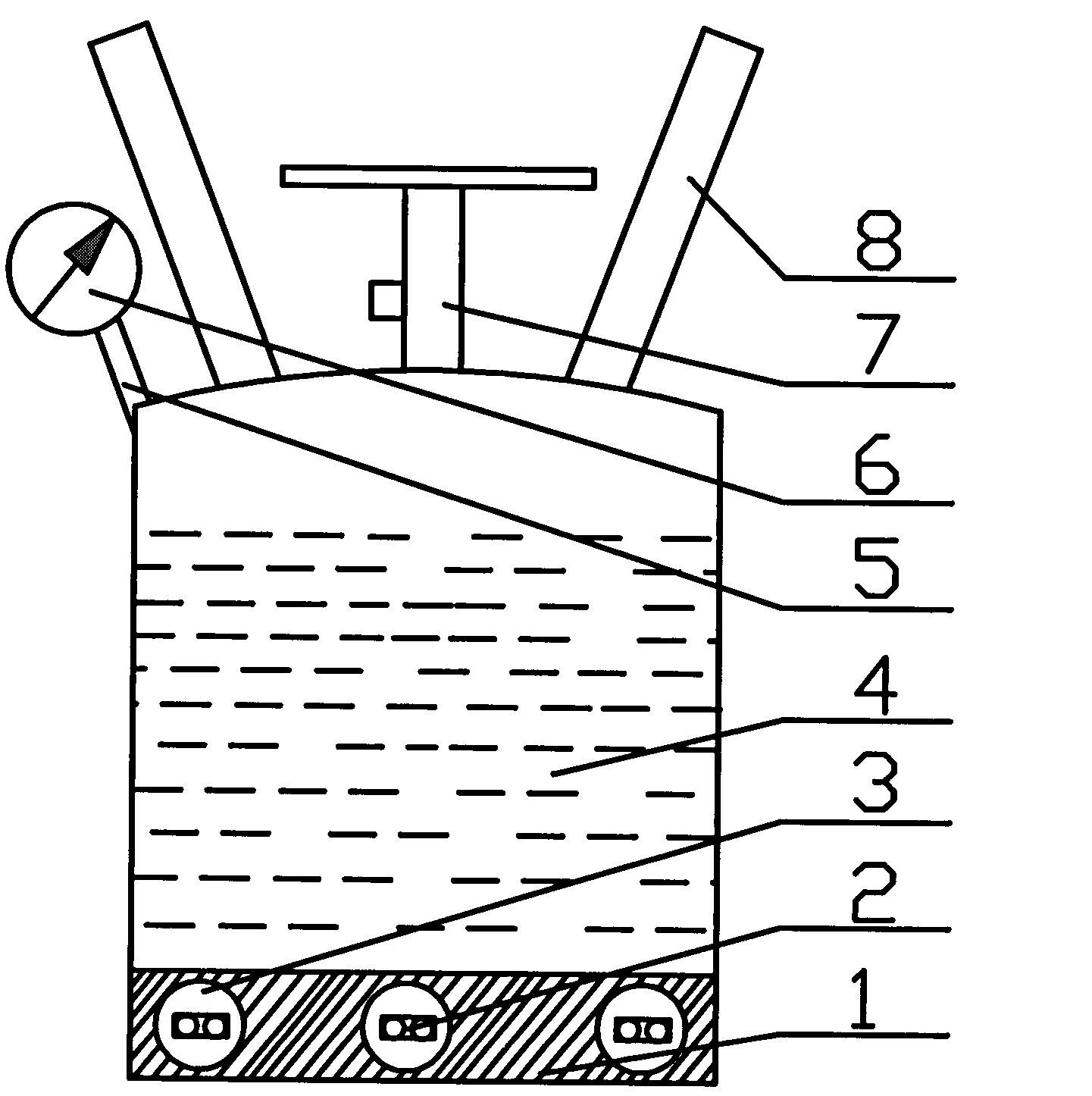

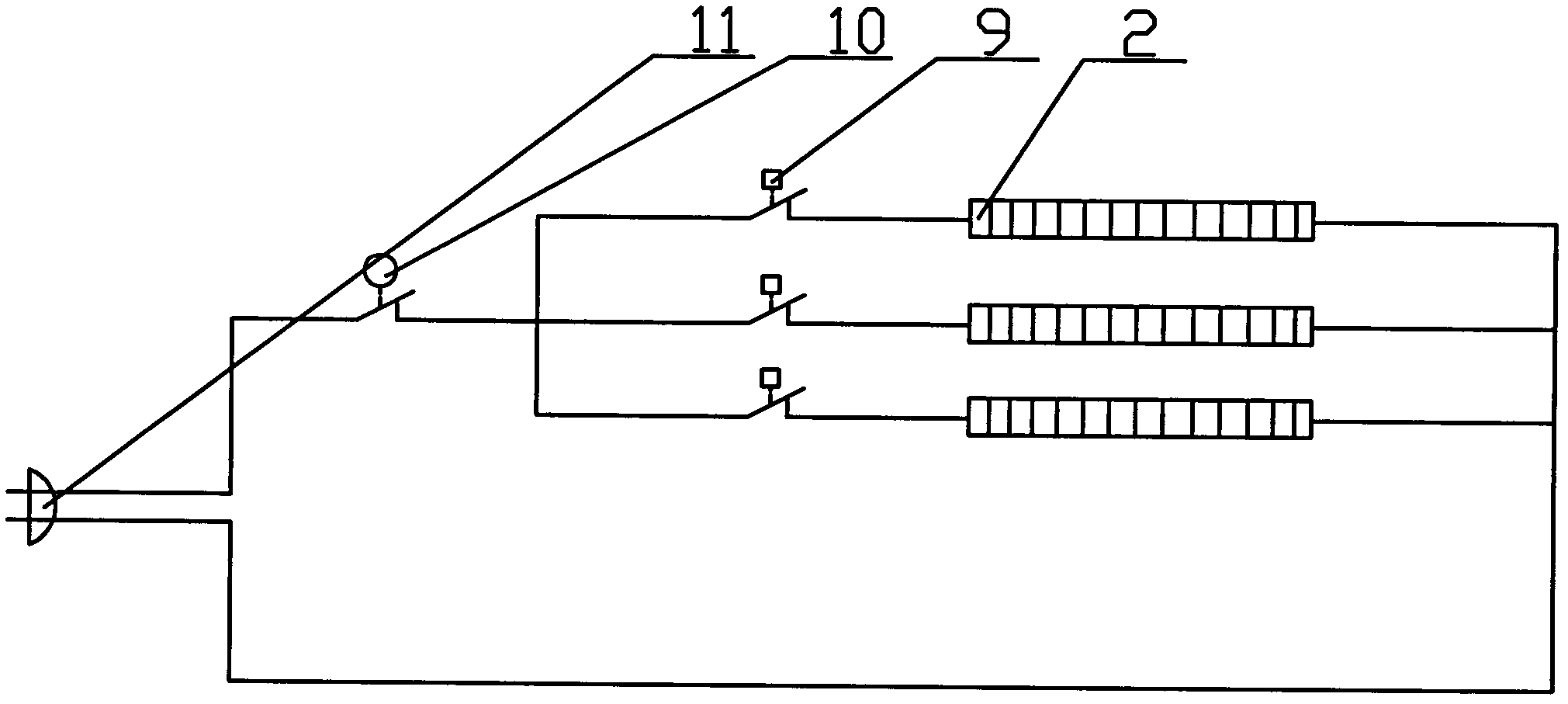

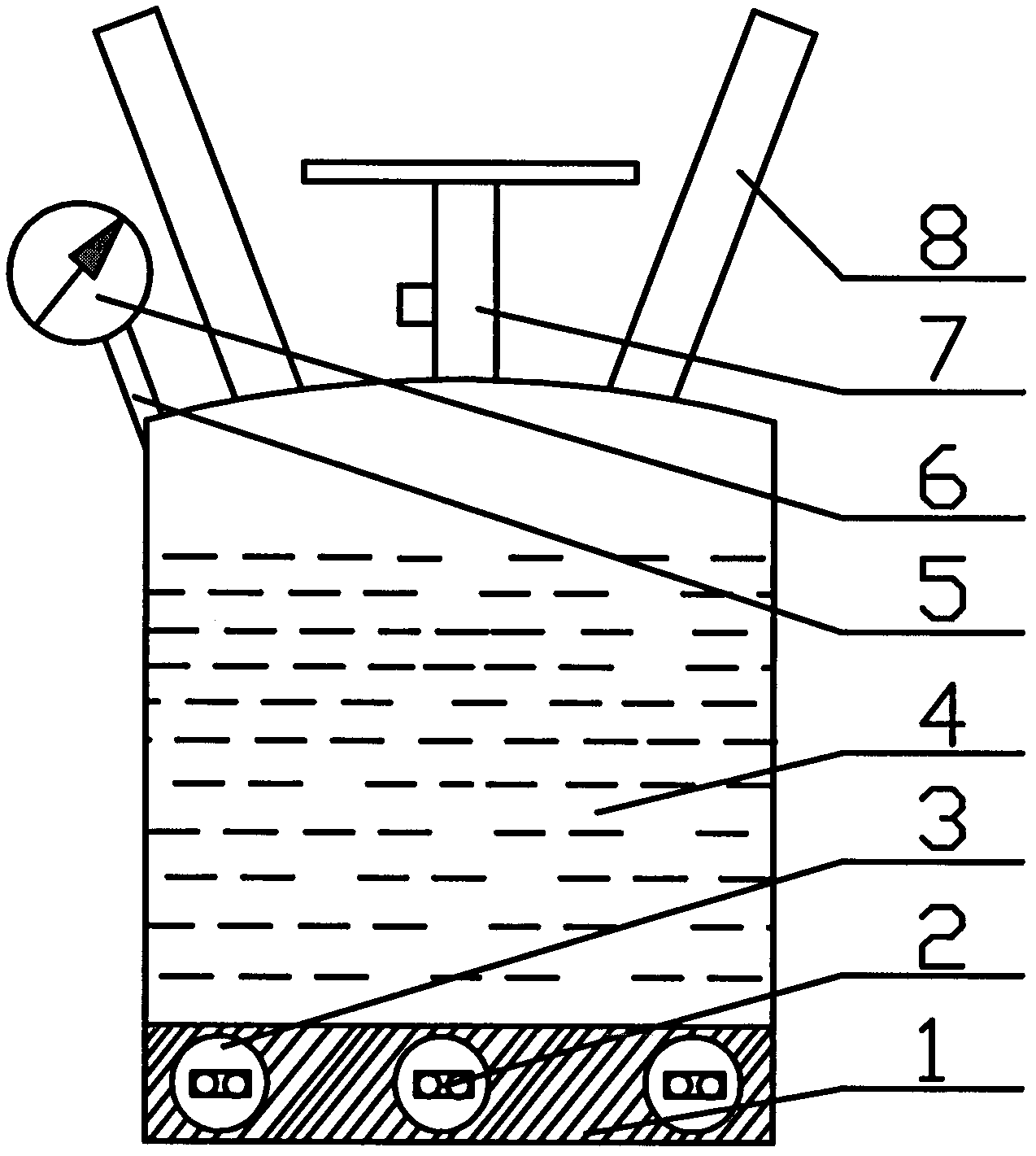

[0017] Such as figure 1 , figure 2 As shown, a steel cylinder for quickly adding refrigerant includes a heat conduction base 1, an electric heater 2, a heating hole 3, a steel cylinder 4, a connecting pipe 5, a pressure gauge 6, a filling valve 7, a handle 8, and a temperature controller 9 , pressure controller 10, plug 11, the heat conduction base 1 is arranged on the bottom of the refrigerant steel cylinder 4, there are three horizontal heating holes 3 with one end closed inside, and electric heaters are respectively installed in the heating holes 3 2.

[0018] The space between the electric heater 2 and the heating hole 3 is covered with heat-conducting glue, and a temperature controller 9 and a pressure controller 10 are connected to the circuit of the electric heater 2 .

[0019] A pressure gauge 6 is installed on the outside of the steel cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com