Infrared thermal image-based thermos cup tester and testing method thereof

An infrared thermal imaging and thermos cup technology, applied in the field of infrared temperature measurement, can solve the problems of unrealistic reaction thermos insulation performance, affecting measurement accuracy, easy oxidation, etc., and achieves a friendly human-computer interaction interface and strong interface expansion capabilities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

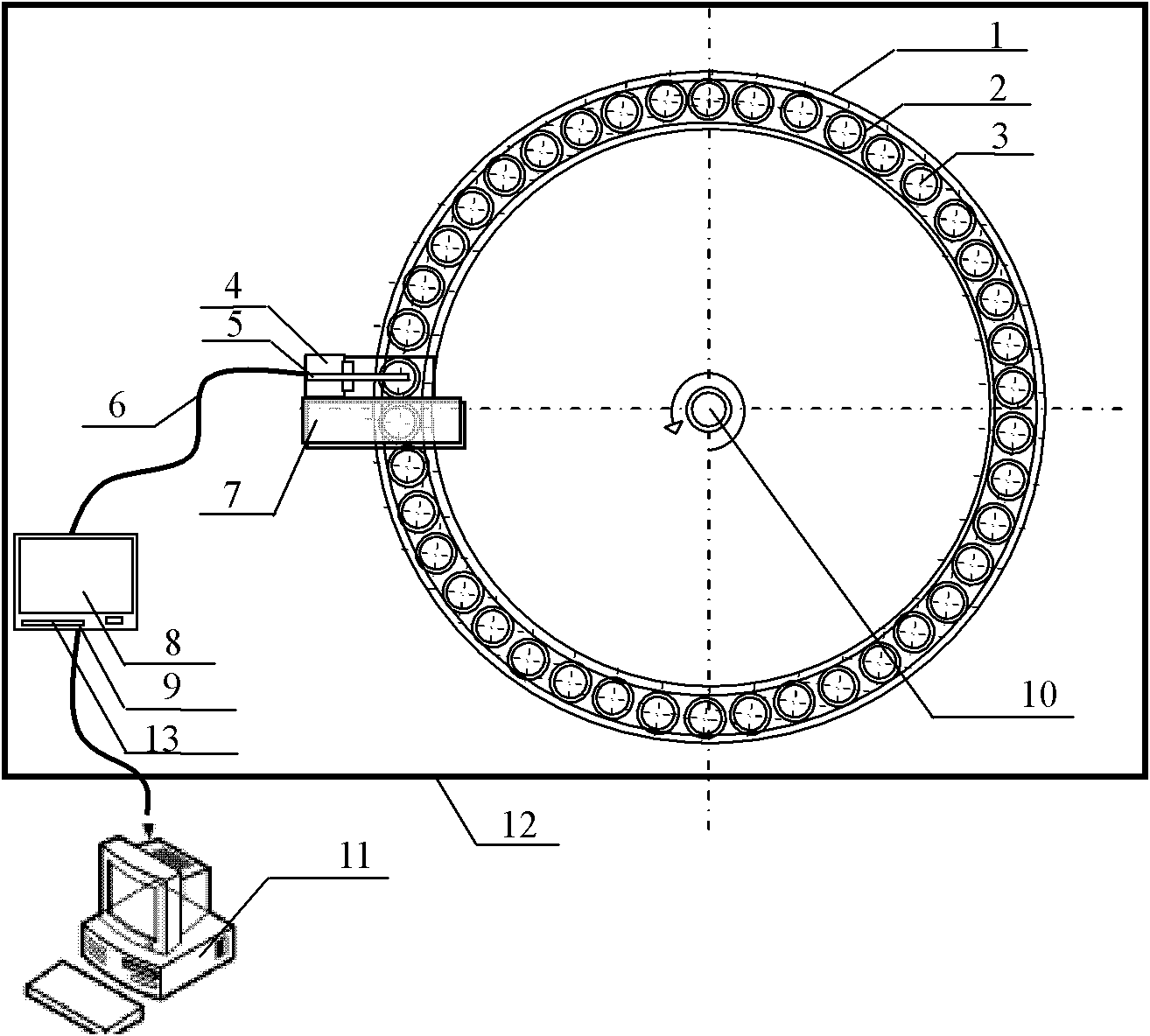

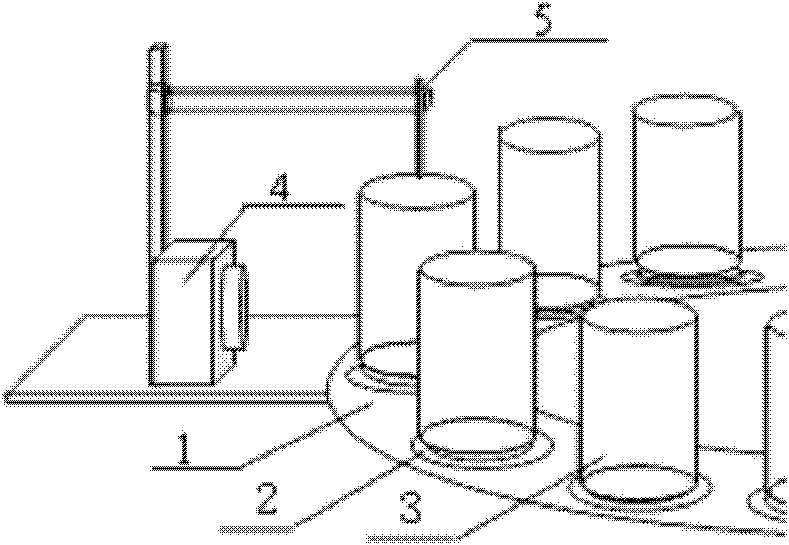

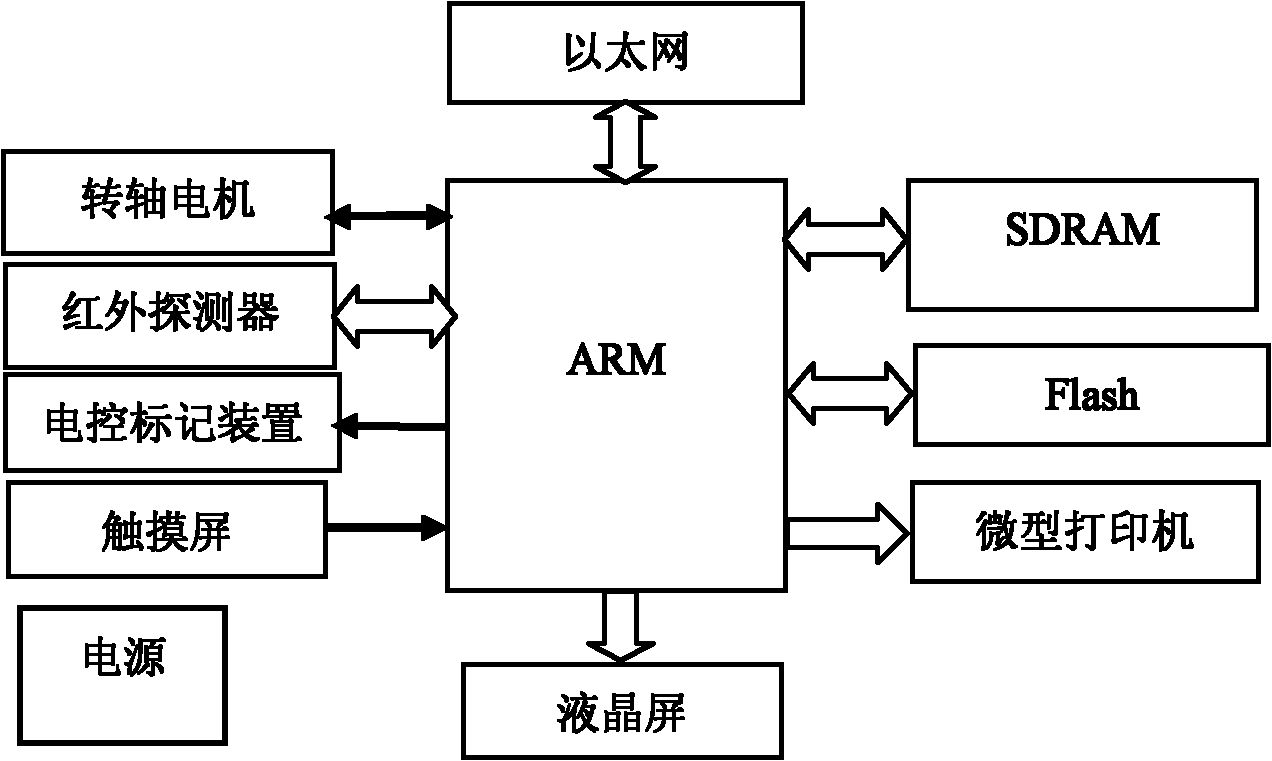

[0022] Such as figure 1 with figure 2 As shown, the thermos cup testing machine based on infrared thermal images of the present invention includes: a box frame 12, a sample turntable 1, a rotating shaft 10 driven by the center of the sample turntable to rotate counterclockwise, and a thermos cup installed on the sample turntable 1. 3 sealing plug 2, infrared detector 4, signal transmission line 6, high temperature gas injection device 7, main control processing board 9 and liquid crystal screen 8 with touch screen.

[0023] Multiple sample thermos cups 3 can be placed on the sample carousel 1 at the same time, the high-temperature gas injection device 7 and the infrared detector 4 are fixed on the box frame 12, and the position of the high-temperature gas injection device 7 corresponds to the standard thermos cup on the sample carousel 1 The position of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com