Deep cycle-resistant lead-acid storage battery plate and manufacturing method

A lead-acid battery, deep cycle technology, applied in the direction of lead-acid battery electrodes, electrode carriers/collectors, etc., can solve the problems of long formation time, no antimony effect on the positive plate, sulfation effect on the negative plate, etc., and achieve short cycle time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

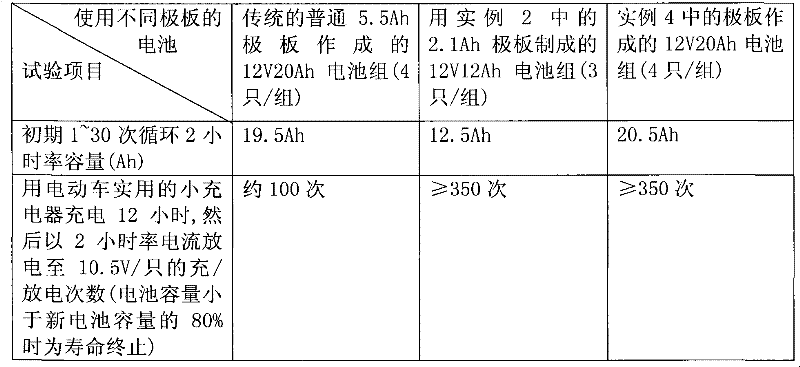

Examples

Embodiment 1

[0038] A kind of manufacture method of deep-cycle lead-acid storage battery polar plate, it comprises the steps:

[0039](1) Preparation of large positive electrode grids: casting large positive electrode grids with alloy material Pb-Ca-Sn-Al, each large positive electrode grid weighs 145-155 grams, of which the components of the Pb-Ca-Sn-Al alloy material The percentage by weight of Sn is: 1.25-1.35% for Sn, 0.05-0.07% for Ca, 0.03-0.035% for Al, and the balance is Pb and unavoidable impurities;

[0040] (2) Preparation of large-scale negative electrode grids: the alloy material Pb-Ca-Sn-Al is used to make large-scale negative electrode grids, and the weight of each large negative electrode grid is 95 to 105 grams; wherein each group of Pb-Ca-Sn-Al alloy materials The weight percent of the component is: Sn 0.15-0.25%, Ca 0.07-0.09%, Al 0.025-0.035%, and the balance is Pb and unavoidable impurities;

[0041] (3) Making lead paste:

[0042] (3.1) Preparation of positive plate...

Embodiment 2

[0052] A deep-cycle resistant lead-acid storage battery pole plate, which comprises a positive pole plate and a negative pole plate, the positive pole plate and the negative pole plate are made by the method of embodiment 1.

Embodiment 3

[0054] A kind of manufacture method of deep-cycle lead-acid storage battery polar plate, it comprises the steps:

[0055] (1) Preparation of large positive electrode grids: casting large positive electrode grids with the alloy material Pb-Ca-Sn-Al, each large positive electrode grid weighs 180-190 grams, of which the components of the Pb-Ca-Sn-Al alloy material The percentage by weight of Sn is: 1.25-1.35% for Sn, 0.05-0.07% for Ca, 0.03-0.035% for Al, and the balance is Pb and unavoidable impurities;

[0056] (2) Preparation of large-scale negative electrode grids: the alloy material Pb-Ca-Sn-Al is used to make large-scale negative electrode grids, and the weight of each large negative electrode grid is 105 to 125 grams; wherein each group of Pb-Ca-Sn-Al alloy materials The weight percent of the component is: Sn is 0.15-0.25%, Ca is 0.07-0.09%, Al is 0.025-0.035%, and the balance is Pb and unavoidable impurities;

[0057] (3) Making lead paste:

[0058] (3.1) Preparation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com