Acoustic processing panel, more particularly adapted for an air intake in an aircraft nacelle

An engine compartment and acoustic treatment technology, which is applied in the direction of machine/engine, power plant air intake combustion, thin material treatment, etc., can solve the problems of turbulent flow and destruction of acoustic treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

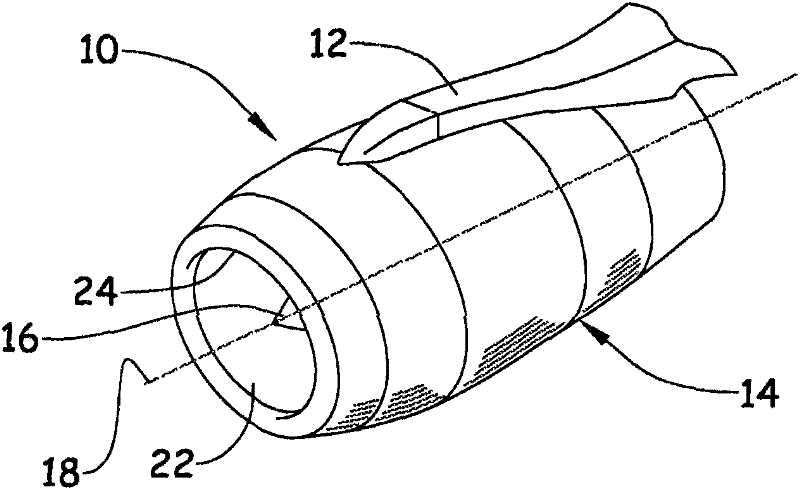

[0026] exist figure 1 Above, the entire propulsion device 10 of the aircraft is shown connected under the wing by means of wing struts 12 . But this whole propulsion unit can be connected to other areas of the vehicle.

[0027] This whole propulsion unit consists of a nacelle 14 in which is arranged substantially concentrically a motor driving a fan (nacelle booster) mounted on its shaft 16 . In the present description, the longitudinal direction corresponds to the reference axis 18 of the nacelle. The plane perpendicular to the longitudinal direction is called the cross-sectional plane.

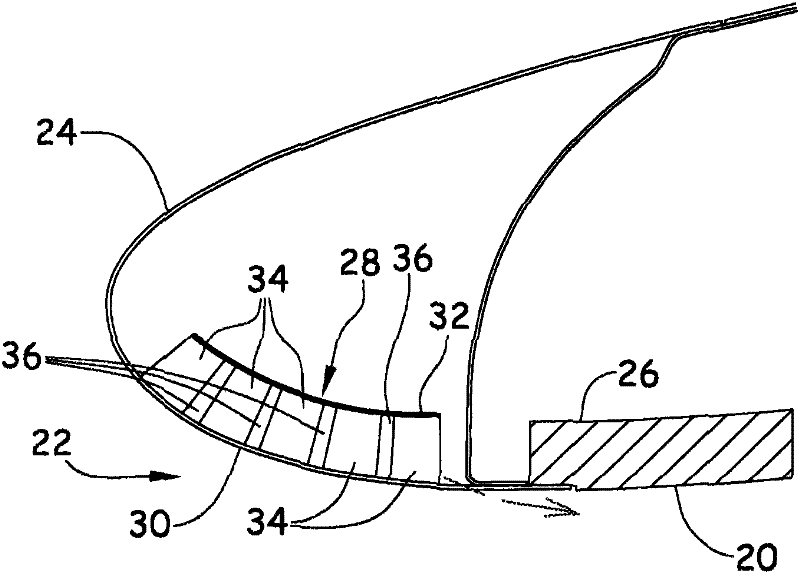

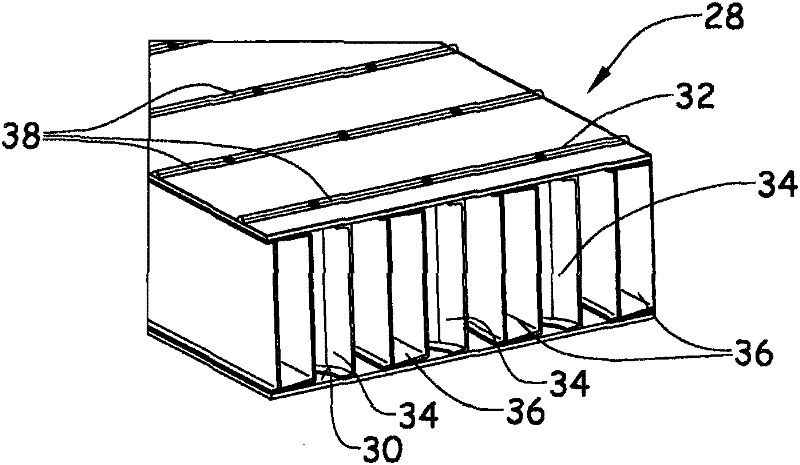

[0028] The nacelle 14 comprises a wall 20 delimiting at the front a duct with an air inlet 22, the first part of the incoming air flow, called the main air flow, driven by the ventilator (nacelle booster), penetrates the motor so as to participate in The second part of the combusted air flow, called the secondary air flow, exits in the annular duct defined by the inner wall 20 of the nace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com