Lens unit, aligning method, image pickup device and method for manufacturing image pickup device

A lens unit, camera device technology, applied in installation, electrical components, optical components, etc., can solve the problems of difficult optical axis alignment, difficulty, etc., and achieve the effect of good optical axis accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

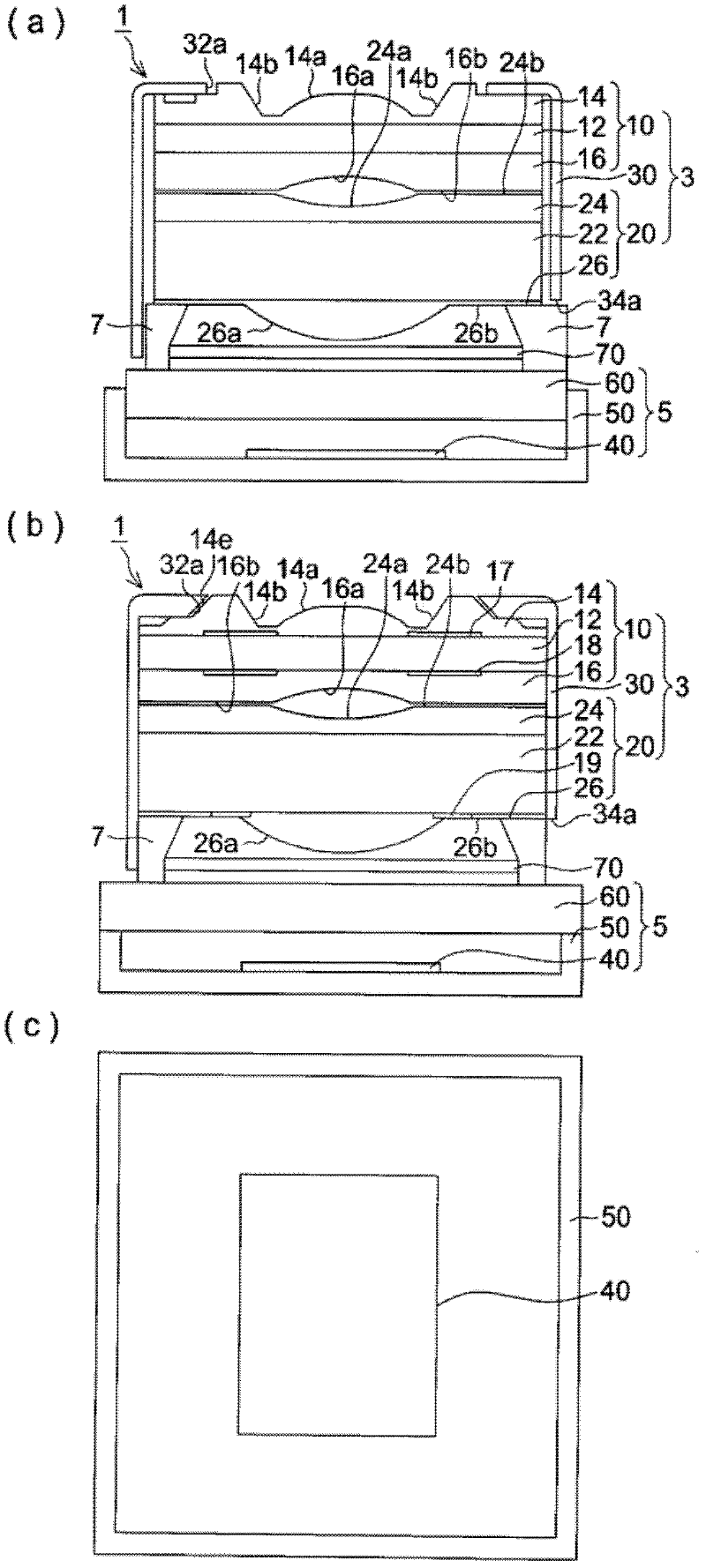

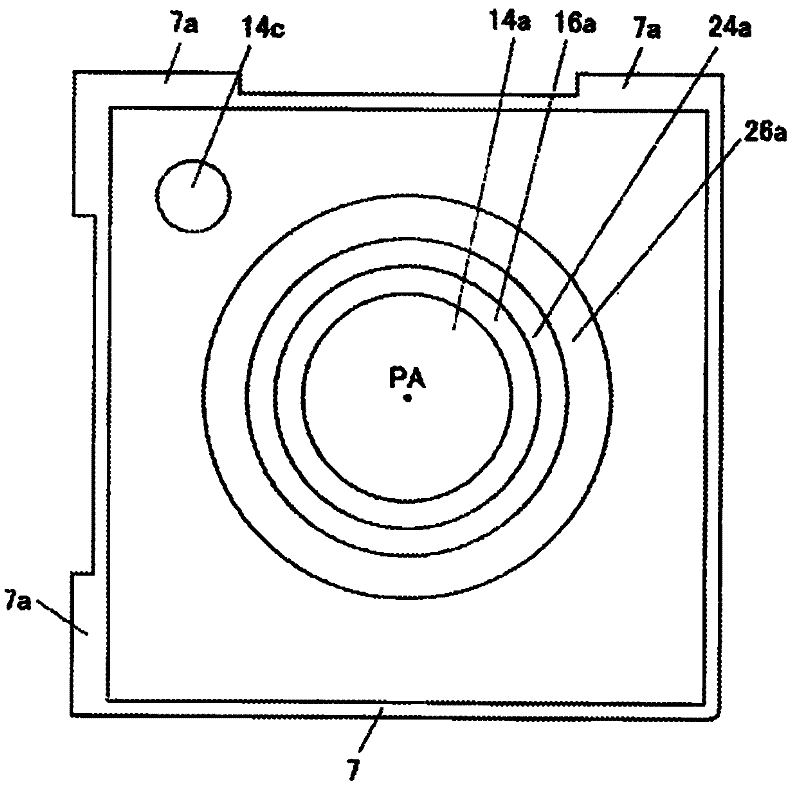

[0062] like figure 1 As shown in (a), the imaging device 1 of the preferred embodiment 1 of the present invention is mainly composed of a lens unit 3, a sensing unit 5, and a spacer 7, and the spacer 7 is interposed between the lens unit 3 and the sensing unit 5. structure.

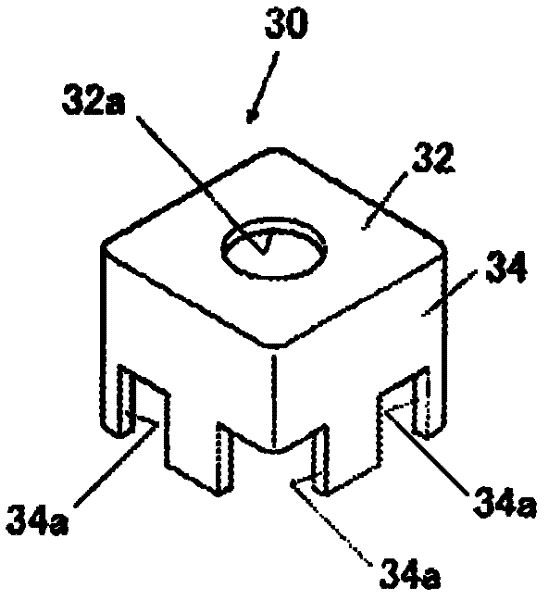

[0063] The lens unit 3 has wafer lenses 10 , 20 and a cover case 30 , and the wafer lenses 10 , 20 are covered by the cover case 30 in a state where the wafer lens 10 is laminated and bonded to the wafer lens 20 .

[0064] The wafer lens 10 has a flat glass substrate 12 . A molded portion 14 is formed on the upper surface of the glass substrate 12 , and a molded portion 16 is formed on the lower surface of the glass substrate 12 .

[0065] A convex lens portion (hereinafter also referred to as a convex lens portion) 14a is formed in the center of the molding portion 14, and an inclined portion 14b is formed on the molding portion 14 to incline upward from the convex lens portion 14a toward the outer per...

Embodiment 2

[0127] The main points different from Embodiment 1 in Embodiment 2 are as follows, and the others are the same as Embodiment 1.

[0128] like Figure 9 , Figure 10 As shown, in the imaging device 2 of the present embodiment 2, the inclined portion 14b and the spacer 7 (including the IR blocking filter 70) on the molding portion 14 of the wafer lens 10 are not provided, and as a structure replacing them, the molding of the wafer lens 20 A spacer portion 26c is formed on the portion 26 .

[0129] like Figure 9 , Figure 11 As shown, the spacer part 26c is composed of an inner inclined part 26d, a bonding part 26e, and an outer inclined part 26f, and is higher than the thickness of the convex lens part 26a.

[0130] The inner inclined portion 26d is inclined downward from the convex lens portion 26a toward the outer periphery. The bonding portion 26 e is flat and is a bonding surface to be bonded to the cover glass 60 of the sensor unit 5 . The outer inclined portion 26f ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com