Gear-box hanger

A gearbox and spreader technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of poor safety, heavy gearbox weight, inconvenient operation, etc., and achieve simple structure, stable lifting connection, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

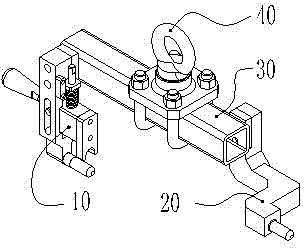

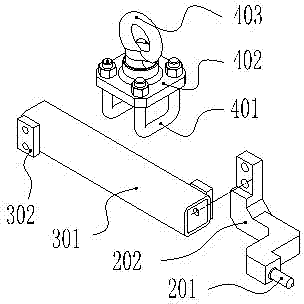

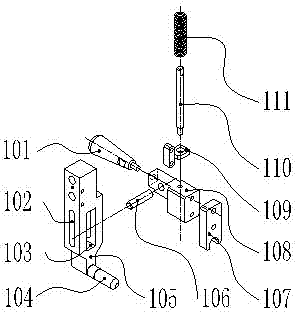

[0021] Such as figure 1 , 2 , 3, the gearbox hanger of the present embodiment includes a crossbeam assembly 30 and a suspension ring assembly 40 installed on the crossbeam assembly 30, the front end of the crossbeam assembly 30 is provided with a front hook 20, and the crossbeam assembly 30 The rear end of the hook is provided with a rear hook 10; the front hook body 202 is provided with a first latch 201 facing forward, the rear hook body 105 is provided with a second latch 104 facing forward, the first latch 201, the second The bolts 104 are arranged horizontally and are all lower than the plane where the beam body 301 is located; a locking device is arranged in the rear hook.

[0022] Such as figure 2 As shown, the front hook body 202 is bent to avoid interference and ensure the lifting center of gravity, and the first bolt 201 is made of 40Cr steel. The upper end of the front hook body 202 is provided with two through holes; the diameter of the first pin 201 is slightl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com