Clutch used for tower crane lifting mechanism

A lifting mechanism and clutch technology, applied in the field of clutches, can solve problems such as short service life, achieve long service life, avoid wear or breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment

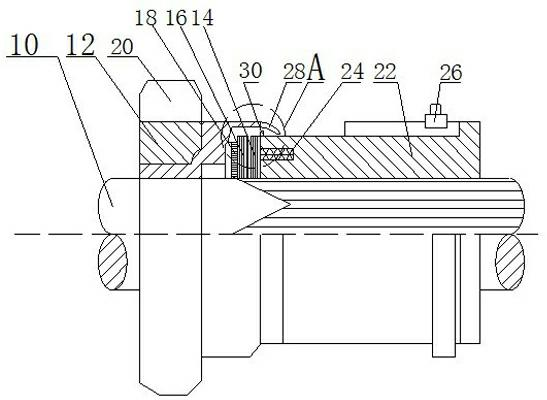

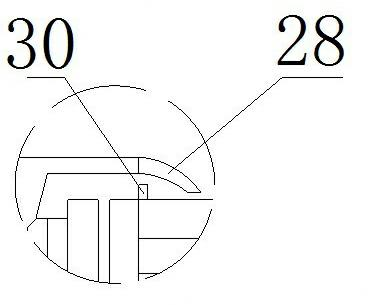

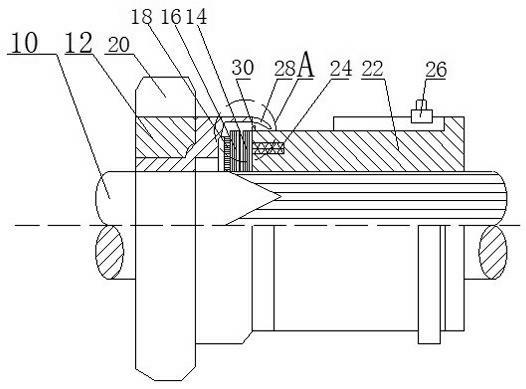

[0014] see figure 1 As shown, a clutch for the hoisting mechanism of a tower crane includes a main shaft 10, a sleeve 12, a driving friction plate 14 and a driven friction plate 16, wherein the sleeve 12, the driven friction plate 16 and the driving friction plate 14 are sequentially set on the On the main shaft 10, an armature 18 is arranged between the driven friction plate 16 and the sleeve 12. The armature 18, the driving friction plate 14 and the driven friction plate 16 are all accommodated in the sleeve 12, and the driven wheel is set on the sleeve 12. 20. An iron core 22 is also set on the main shaft 10, and a coil 24 is arranged in the iron core 22. The active friction plate 14 is in contact with the iron core 22, and a slip ring 26 is arranged on the iron core 22, and a slip ring 26 is arranged on the sleeve 12. One end of the rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com