Hybrid optical cable

A hybrid and optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of inconspicuous number of optical fibers and limited fiber core density of optical cables, and achieve the effect of small outer diameter of optical cable, stable and reliable optical performance, and large core density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

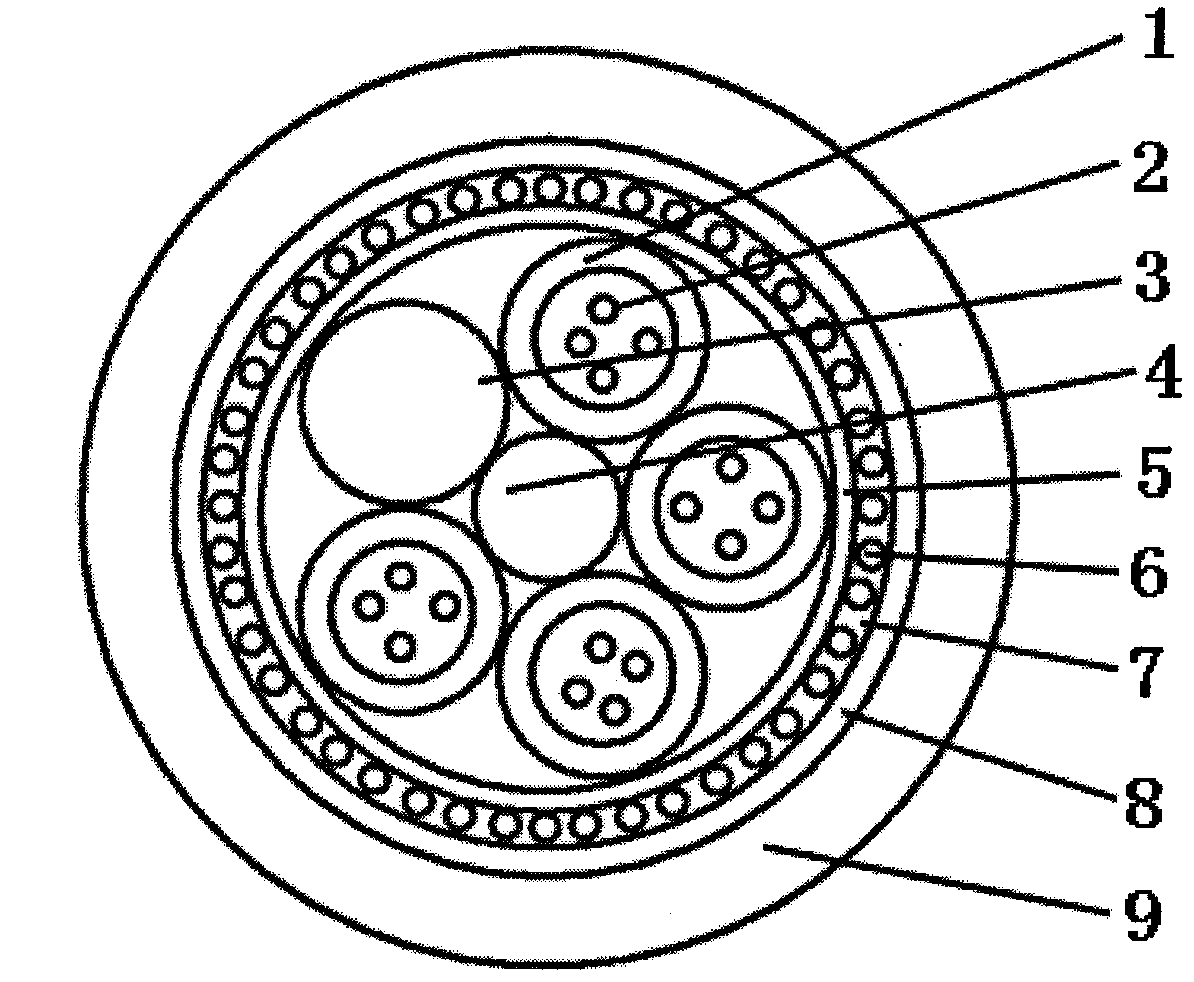

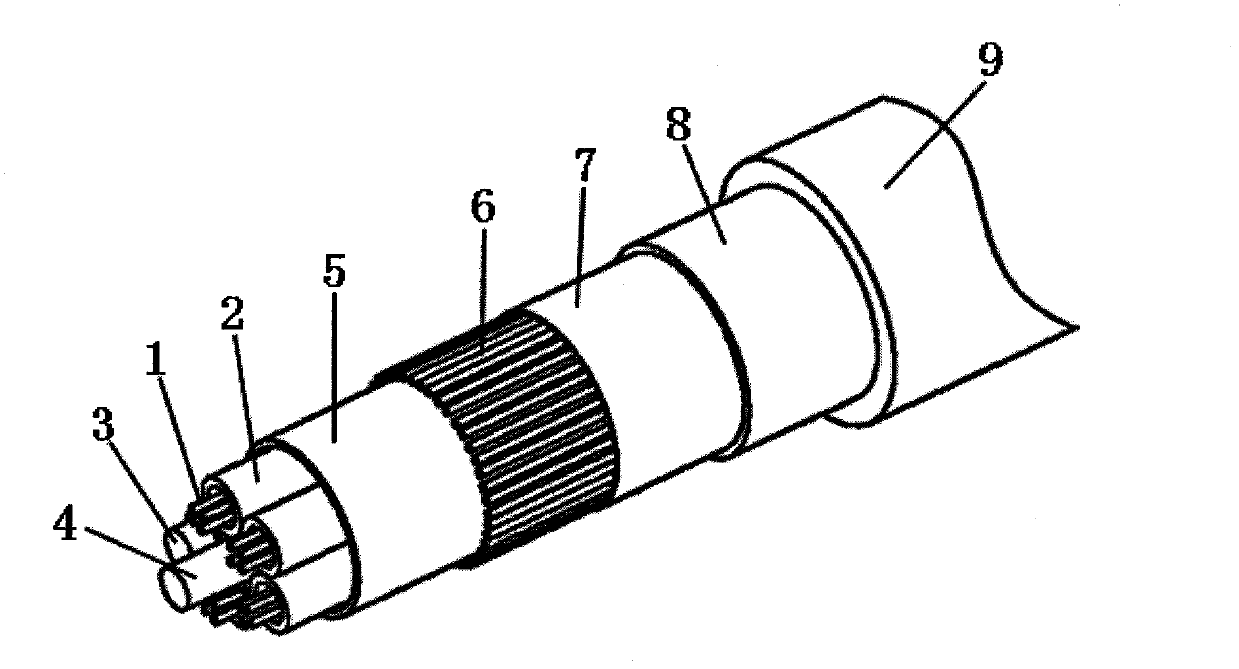

[0031] See figure 1 and figure 2 , a hybrid optical cable, is characterized in that it comprises a center strength member 4 in the center, a plurality of strands twisted around the center strength member SZ or unidirectional helical stranding distribution, and coated on the outside of the strands The isolation layer 5, the optical fiber ribbon 7 longitudinally coated on the isolation layer, the protective layer 8 wrapped on the optical fiber ribbon, and the sheath layer 9 extruded on the protective layer; 4 of the twisted parts are inner A loose tube 1 containing a plurality of optical fibers 2; the twisted part except the loose tube is a solid filling rope 3; the optical fiber ribbon contains a plurality of optical fibers 6 placed parallel to each other; the optical fiber The axis of the fiber is parallel to the axis of the central strength member; the optical fiber ribbons are connected end to end but not connected; the central strength member is steel wire; the material o...

Embodiment 2

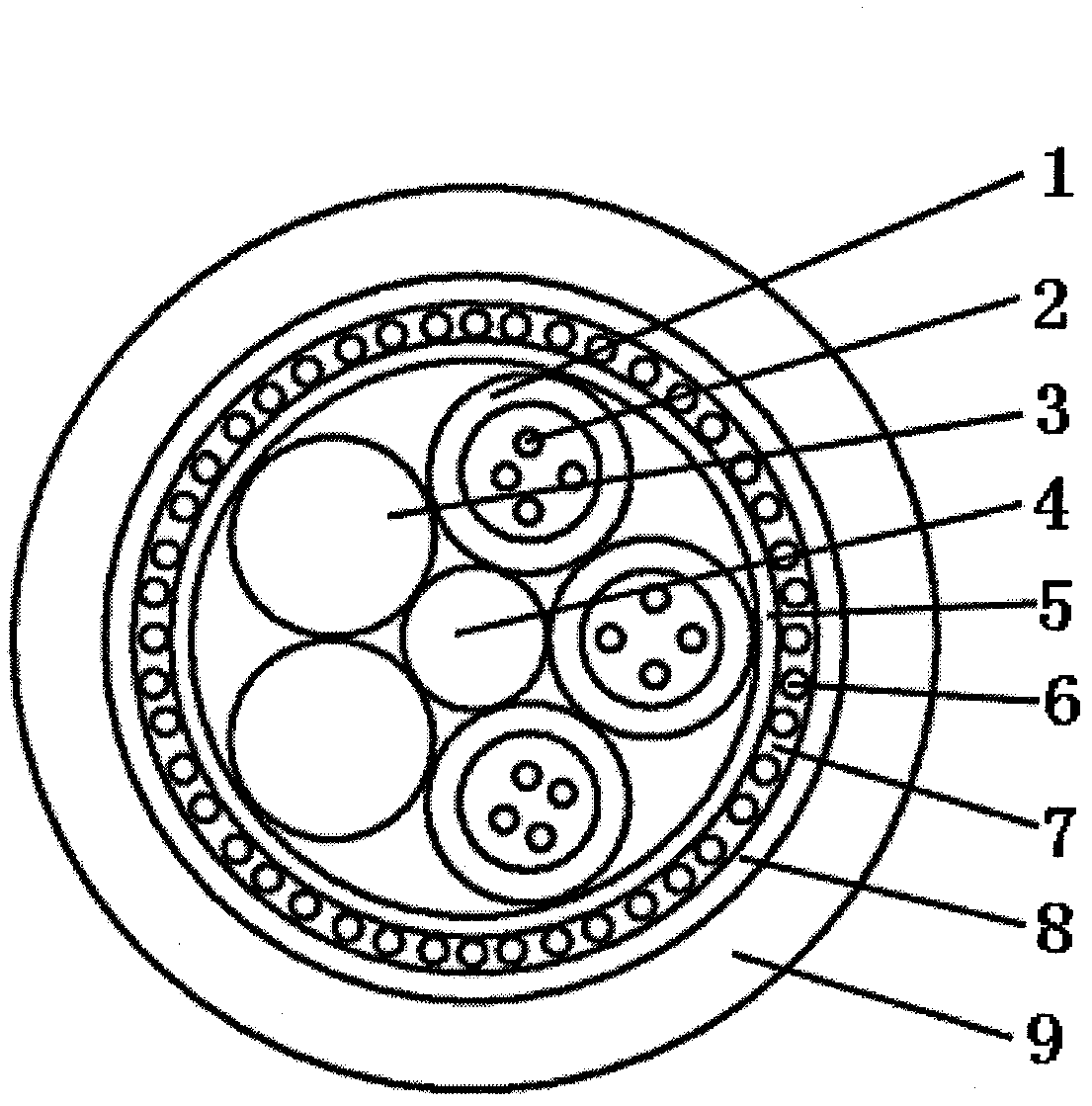

[0033] please see image 3 and refer to figure 2 , a hybrid optical cable, is characterized in that it comprises a center strength member 4 in the center, a plurality of strands twisted around the center strength member SZ or unidirectional helical stranding distribution, and coated on the outside of the strands The isolation layer 5, the optical fiber ribbon 7 longitudinally coated on the isolation layer, the protective layer 8 wrapped on the optical fiber ribbon, and the sheath layer 9 extruded on the protective layer; 3 of the twisted parts are inner A loose tube 1 containing a plurality of optical fibers 2; the twisted parts except the loose tube are two solid filling ropes 3; the optical fiber ribbon contains a plurality of optical fibers 6 placed parallel to each other; the optical fiber The axis of the fiber is parallel to the axis of the central strength member; the optical fiber ribbons are connected end to end but not connected; the central strength member is a gla...

Embodiment 3

[0035] please see Figure 4 and refer to figure 2 and image 3 , a hybrid optical cable, basically the same as the implementation example 2, the difference is that: the three loose tubes are separated by two filling ropes, one is one and the other is two, so that the optical cable The weight is more balanced.

[0036] Of course, the hybrid optical cable described in any of the above implementation examples is characterized in that the optical fiber ribbon can be multiple, the head end of the next optical fiber ribbon is connected to the tail end of the previous optical fiber ribbon, and the last optical fiber ribbon The tail end of the ribbon is connected to the beginning and end of the first optical fiber ribbon.

[0037] Of course, the hybrid optical cable described in any of the above implementation examples is characterized in that the central strength member is a steel wire or a steel strand or a glass fiber reinforced plastic rod.

[0038]Of course, the hybrid optic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com