Method for monitoring working state of electro-hydraulic system of engineering machine

A working state monitoring, engineering machinery technology, applied in the direction of program control, computer control, general control system, etc., can solve problems such as not much help or prompts for troubleshooting, limited screen size, limited display capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

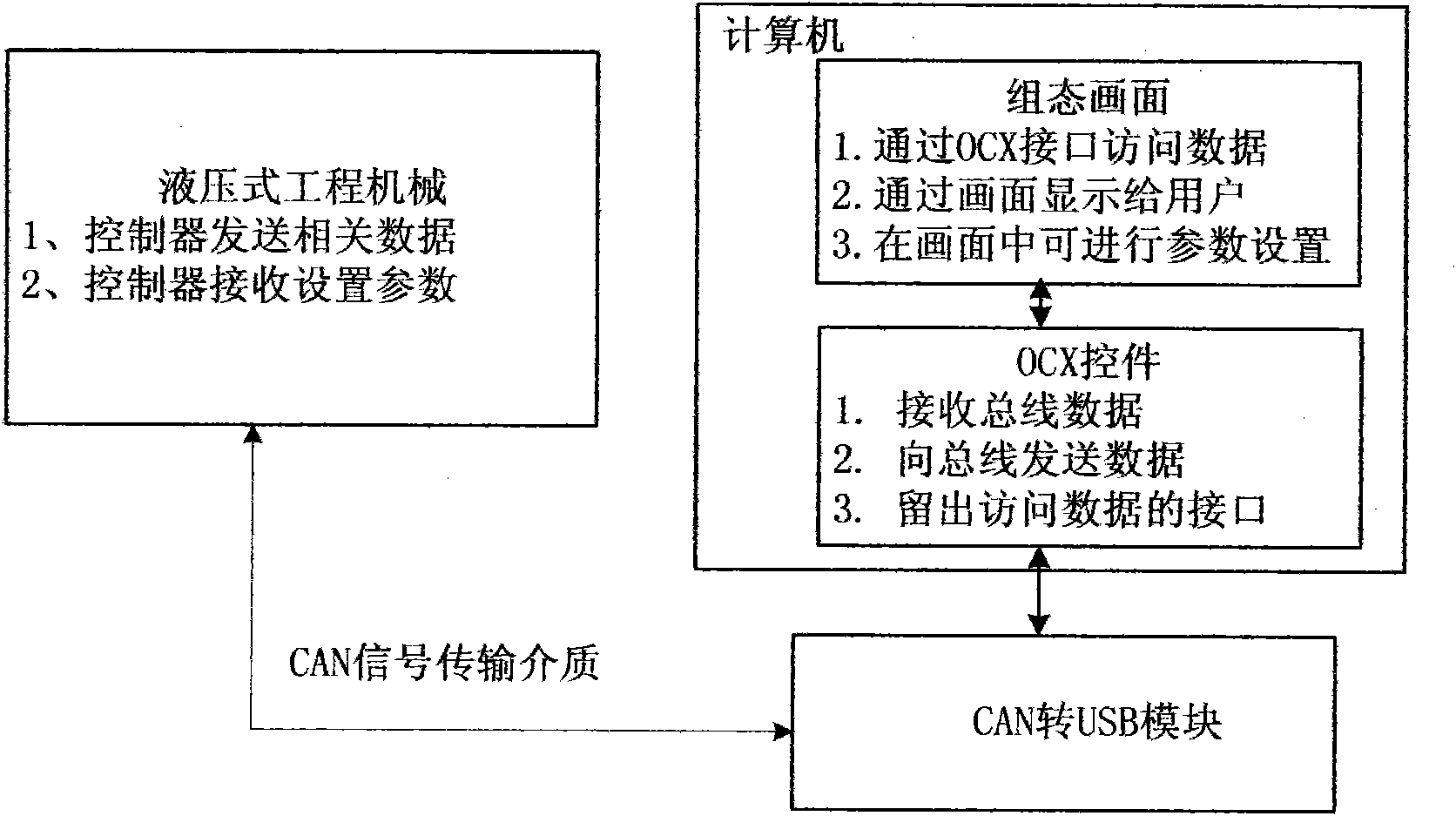

[0014] The present invention is realized by computer, Covey Provisit software, and German Sitai USB-CANmodul1 module. The implementation mode of the present invention is introduced in detail below, totally 3 steps:

[0015] 1: Install the driver program of the German Sytech USB-CANmodul1 module on the computer.

[0016] 2: Write and register the OCX control. The writing of the control is briefly introduced as follows:

[0017] First, create a new ActiveX project scp_can in Microsoft's VC, add a new class UcanIntf, this class adds the Initialize function to initialize, so that the USB to CAN module has the ability to receive and send data; this class increases the function of sending and receiving bus data; in this class After the class receives the data on the CAN bus, it sends the message "USBCAN_EVENT_RECIEVE" to the parent class.

[0018] Secondly, add two arrays, one array is used to register the bus ID, and the other array is used to analyze the specific content of all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com