Miniature multi-section magnetic ring coiling machine

A wrap-around, small-scale technology, applied in the field of small magnetic ring processing equipment, can solve the problems of high labor cost, low operation efficiency, and limited machine processing range, etc., and achieve the effect of low labor cost, high processing efficiency, and reduced labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

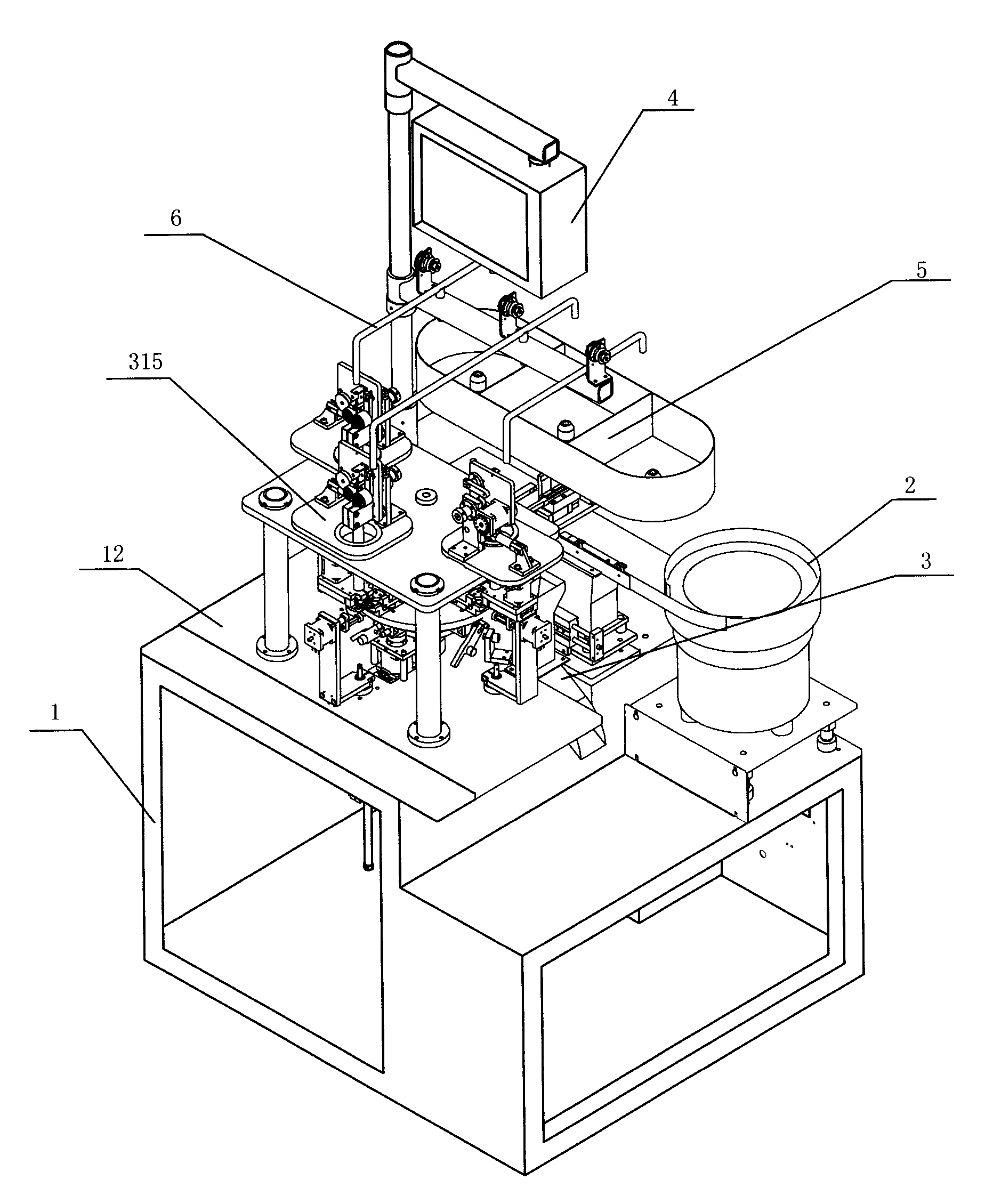

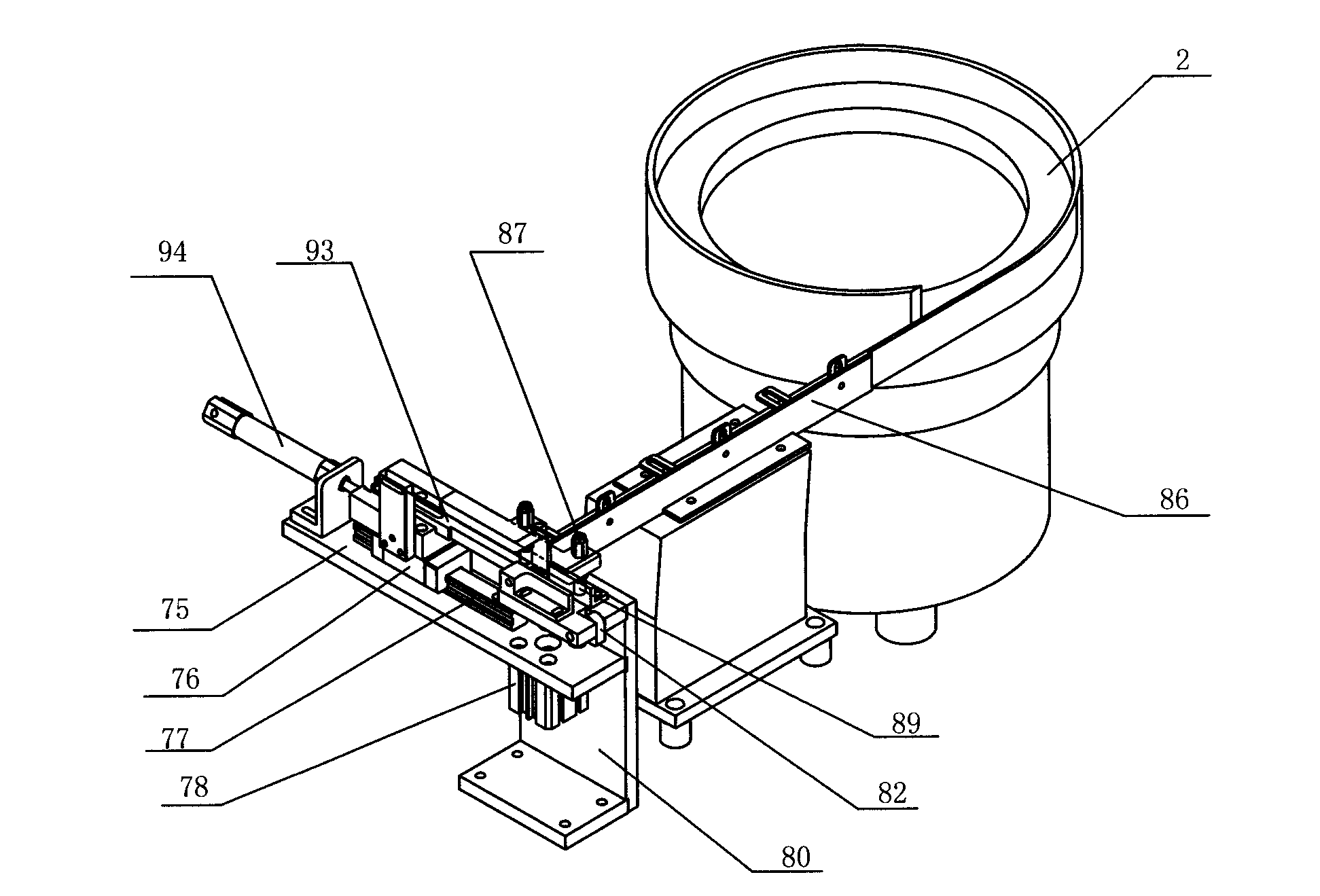

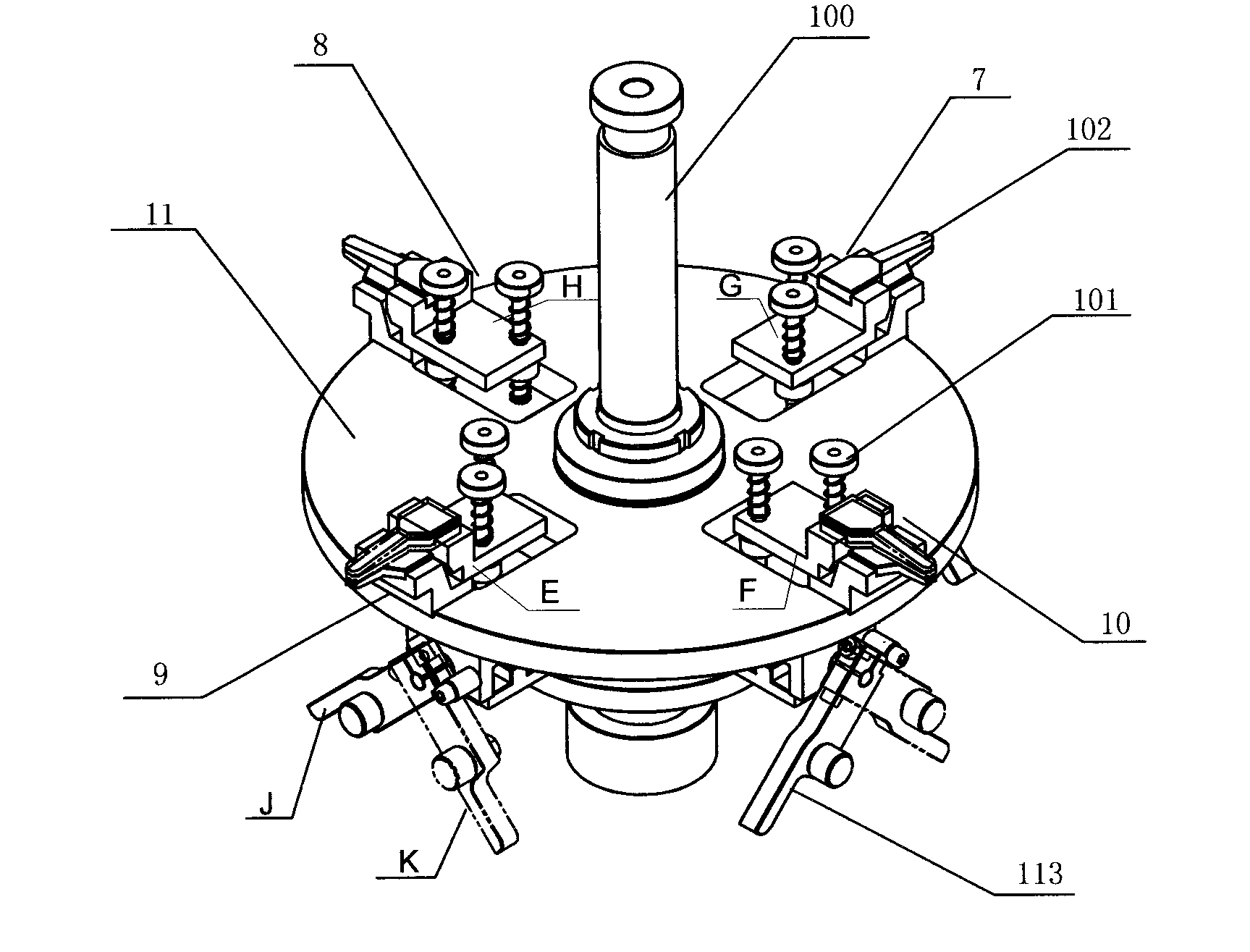

[0029] Embodiment: With reference to the accompanying drawings, a multi-stage small-scale magnetic winding machine includes a bottom plate 12, a circular working turntable 11, a main shaft 100, a vibrating hopper 2, a dropping hopper 3, an operation box 4, and a material filling machine on a frame 1. Frame 5 and wire frame 6, wire feeding mechanism, winding mechanism, and a workpiece clamping device is provided every 90° on the working turntable 11, and each workpiece clamping device corresponds to respectively: feeding station 7, first winding Line station 8, second winding station 9, third winding station 10; each workpiece clamping device is provided with an upper part pressing plate 102 and a lower part pressing plate 104, and the lower part pressing plate 104 passes through the lower part pressing plate The seat 105 is connected on the working turntable 11, the upper part pressing plate 102 is connected on the upper part pressing plate seat 103 with the guide rod 101, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com