High-power solar assembly with dual junction boxes and production method thereof

A technology of solar modules and double junction boxes, which is applied in the manufacture of electrical components, semiconductor devices, and final products. It can solve problems such as inability to make higher power components, affect product yield, and poor components, and reduce welding cracks. , increase power, reduce the effect of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

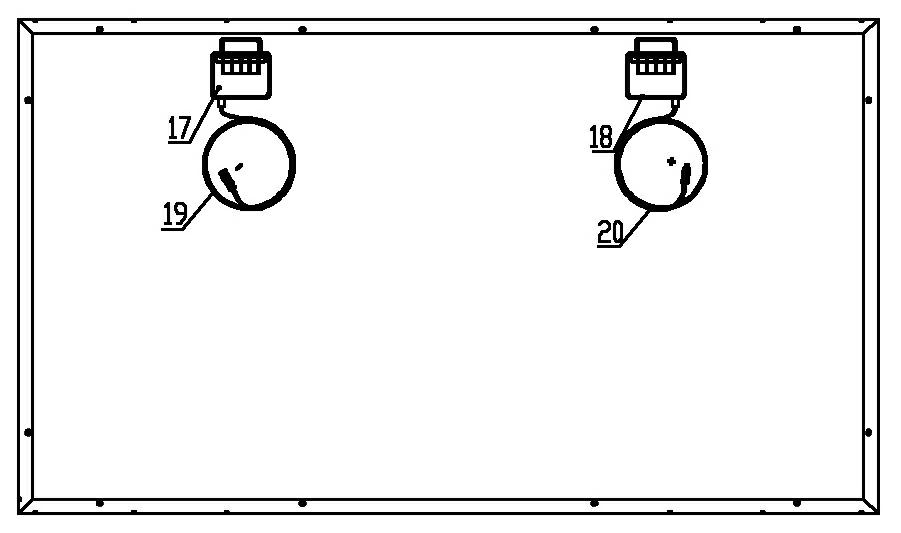

[0029] Embodiment: According to the following steps, double junction box high-power solar modules are produced:

[0030] (1) Cell sorting: Sorting the appearance of cells, picking out defective products, and classifying them according to different color grades;

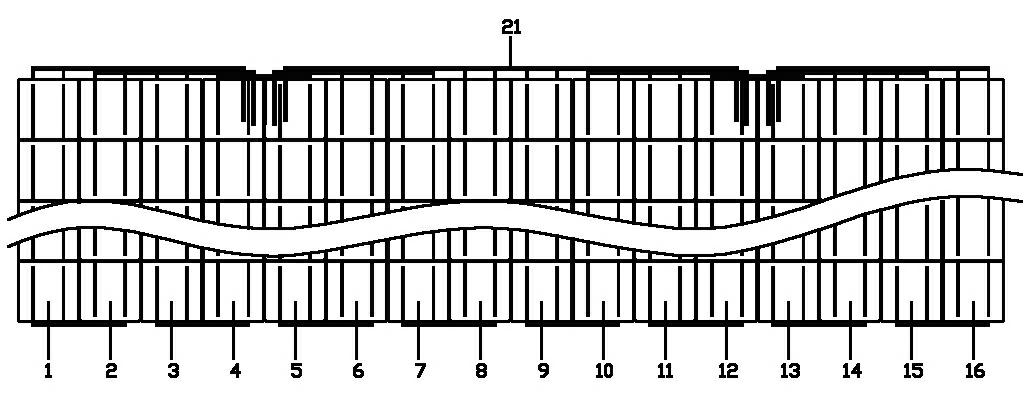

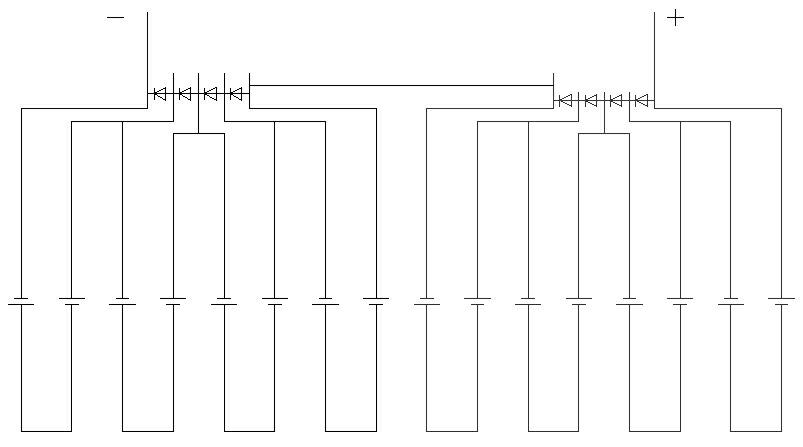

[0031] (2) Material preparation: including cutting of welding strips, confluence strips, TPT, EVA, soaking and drying of welding strips; according to figure 2 The stackup diagram of the double junction box solar module, calculate the actual length of the used ribbon and busbar, and cut the ribbon and busbar according to the size, so as to facilitate the lamination without cutting;

[0032] (3) Battery string welding: such as Figure 4 , Use the string welding template with the engraved line 22 to accurately position the ribbon, and the solar cells are welded into a battery string at a temperature of 320-330°C through the ribbon;

[0033] (4) Lamination: such as figure 2 , firstly, the battery strings are arranged...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap