An insulating sleeve for high-voltage cable connectors

A high-voltage cable and connector technology, applied in the electrical field, can solve the problems of short distance, inability to cooperate with transformers, and creepage, etc., so as to increase the surface distance and prevent creepage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

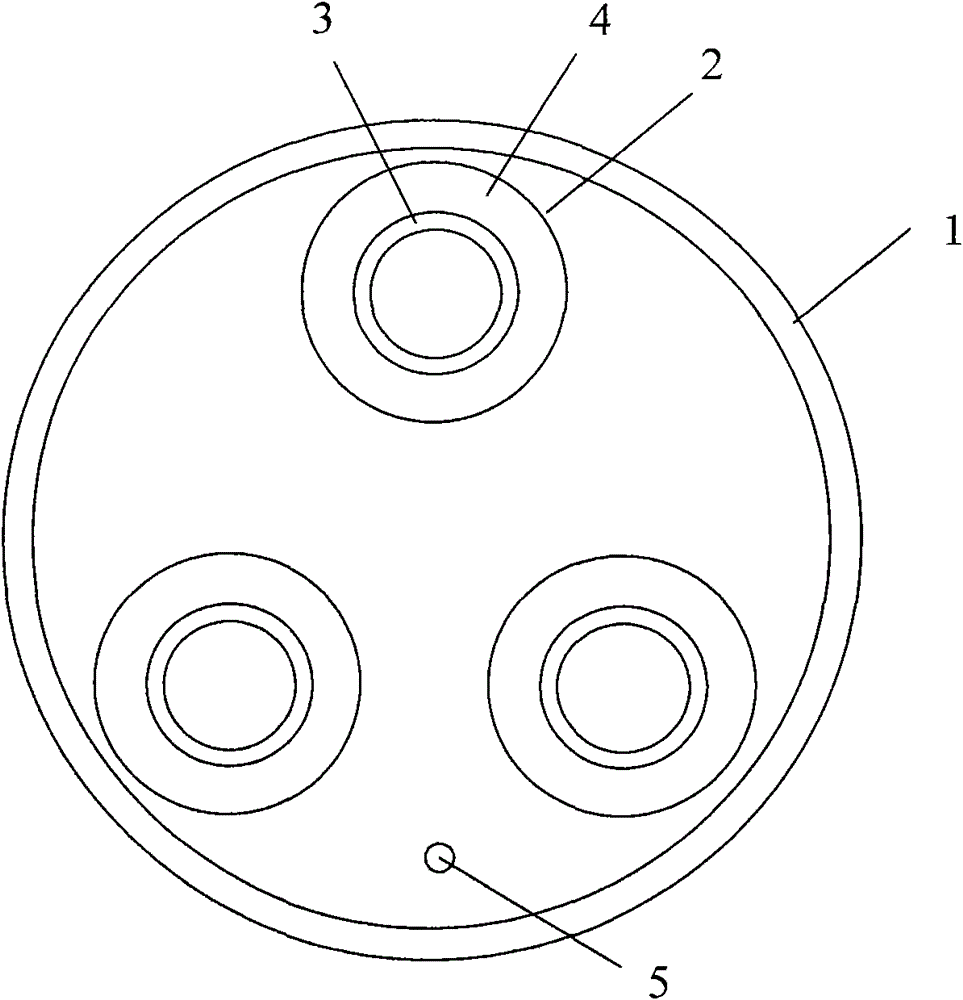

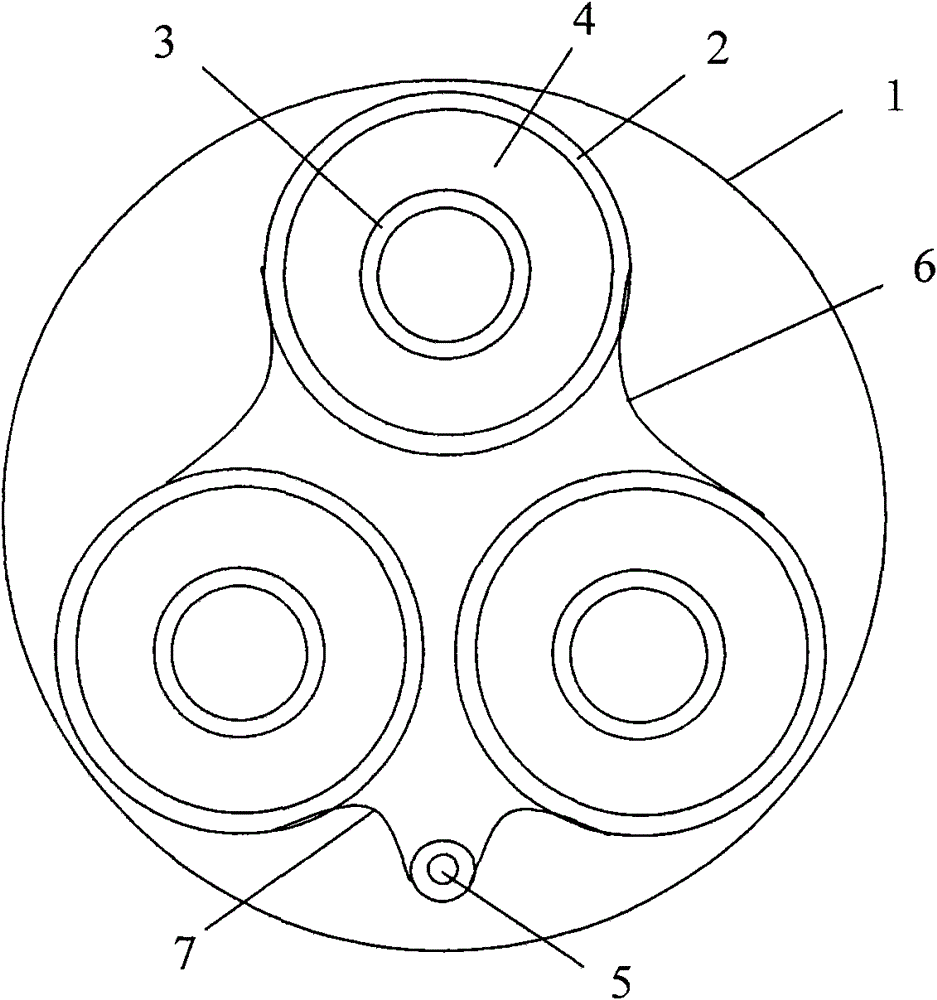

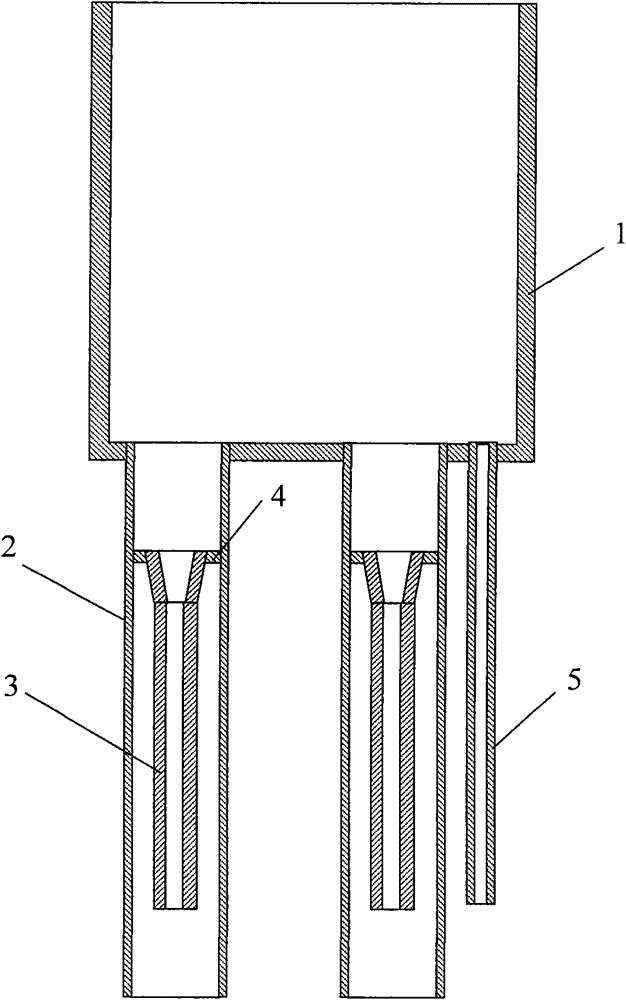

[0016] Such as figure 1 , figure 2 with image 3 As shown, the insulating sleeve used for high-voltage cable connectors of the present invention is composed of an insulating shell 1, wherein the insulating shell 1 is cylindrical, the top surface of the insulating shell 1 is open, and the insulating shell 1 There are three insulating tubes 2 extending downwards from the bottom surface of the housing. The axial direction of any one of the insulating tubes 2 is parallel to the axial direction of the insulating housing 1. Each insulating tube 2 is provided with an insulating inner tube 3. Any one of the insulating inner tubes 3 is coaxial with the insulating tube 2, the length of the insulating inner tube 3 is less than the length of the insulating tube 2, the outer diameter of the insulating inner tube 3 is smaller than the inner diameter of the insulating tube 2, any insulating tube 2 is provided with a radial partition 4 on the inner side of the upper part, the radial partit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com