Single-control thermostatic cartridge and mixer faucet including such a cartridge

A technology of constant temperature components and core parts, which is applied in the directions of temperature control, transportation and packaging, non-electric variable control, etc., and can solve problems such as large space, occupation, and incompatibility of the structural restrictions of constant temperature core parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

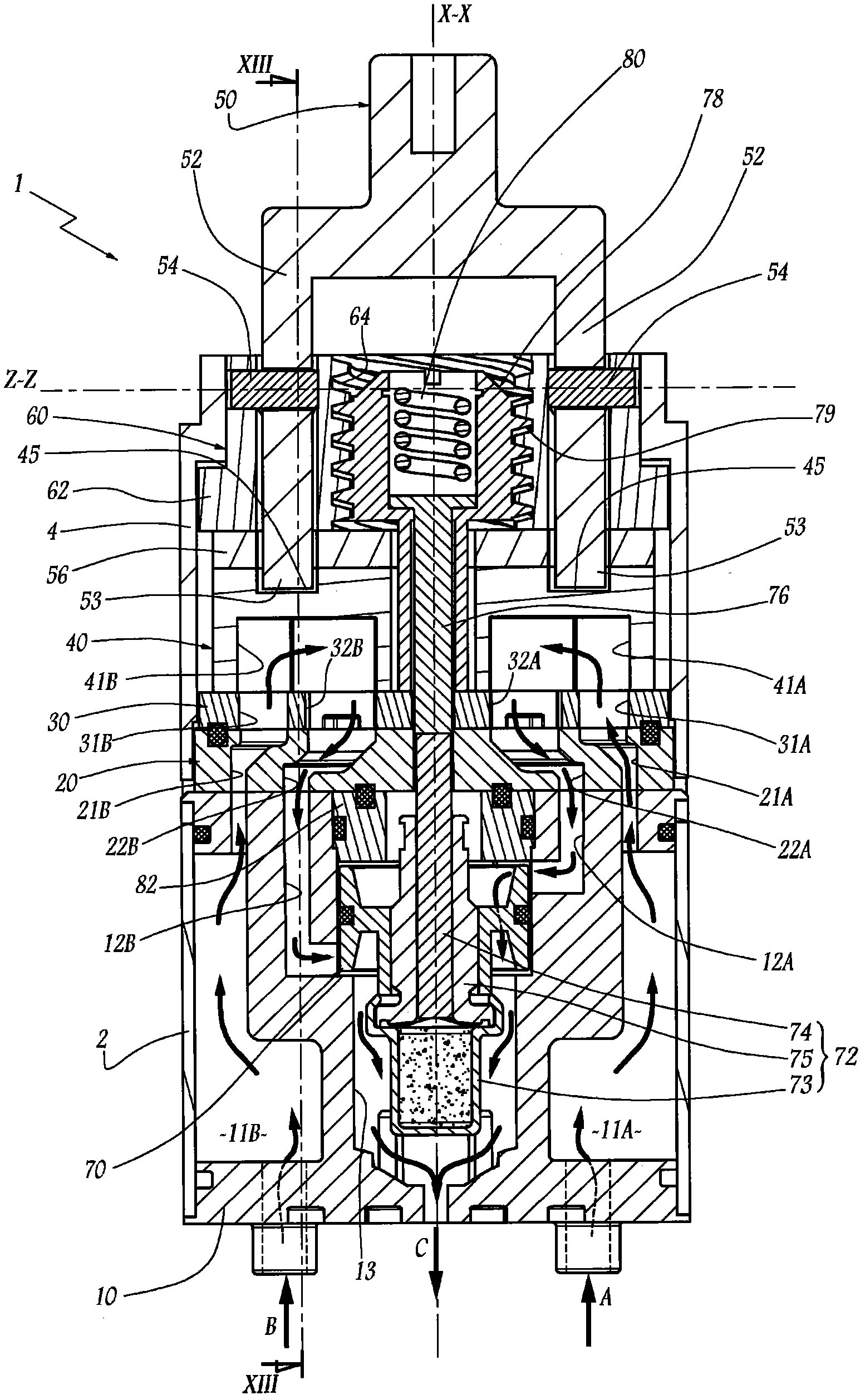

[0025] figure 1 In is shown a thermostatic core 1 extending longitudinally about a central axis X-X and intended to equip a mixing tap for water. The following instructions are based on the figure 1 The lower part of the core piece shown in the lower part was made.

[0026] The core 1 has an upper tubular casing 2 and a lower tubular casing 4 centered on the axis X-X and fixed coaxially to each other.

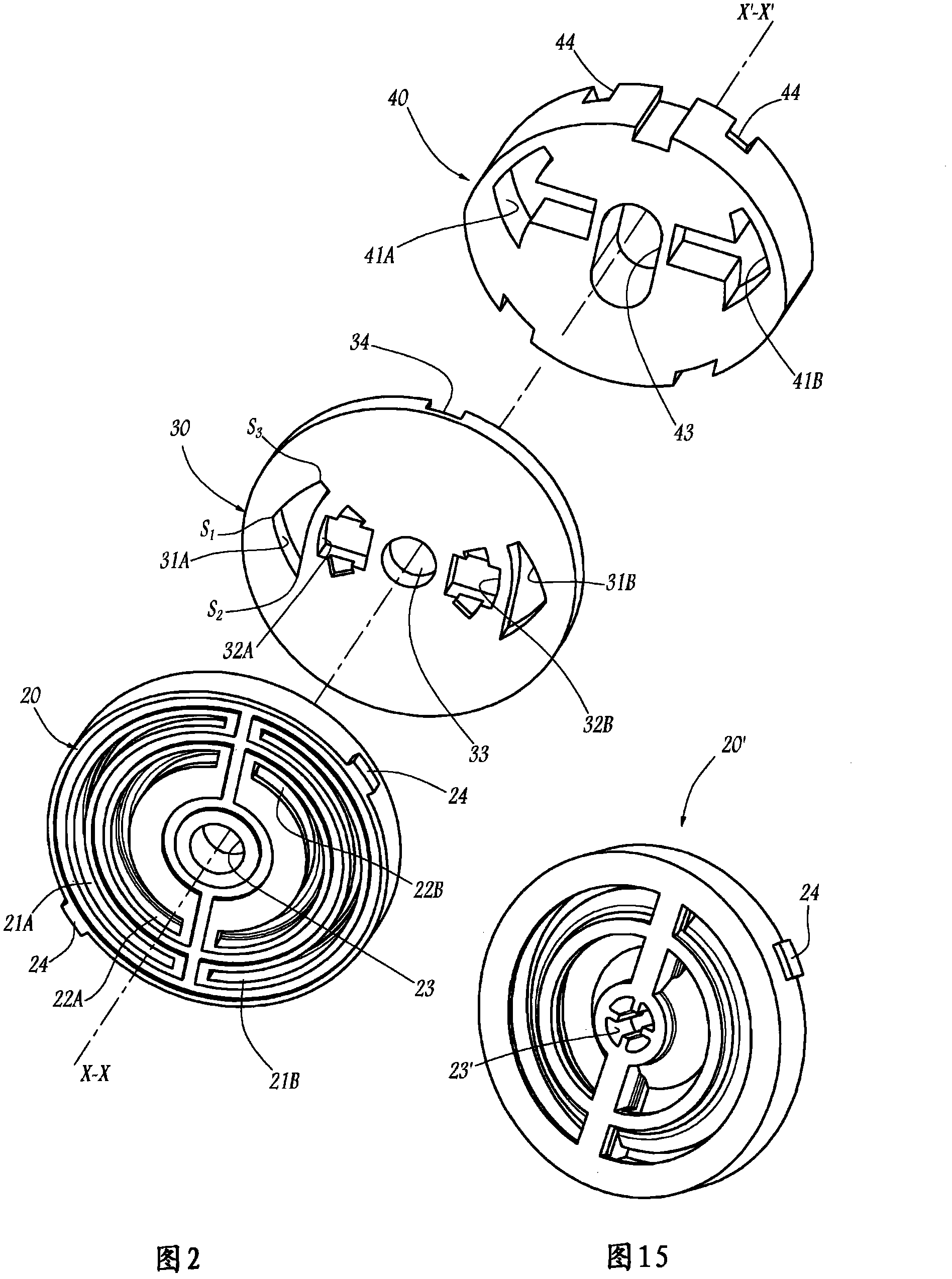

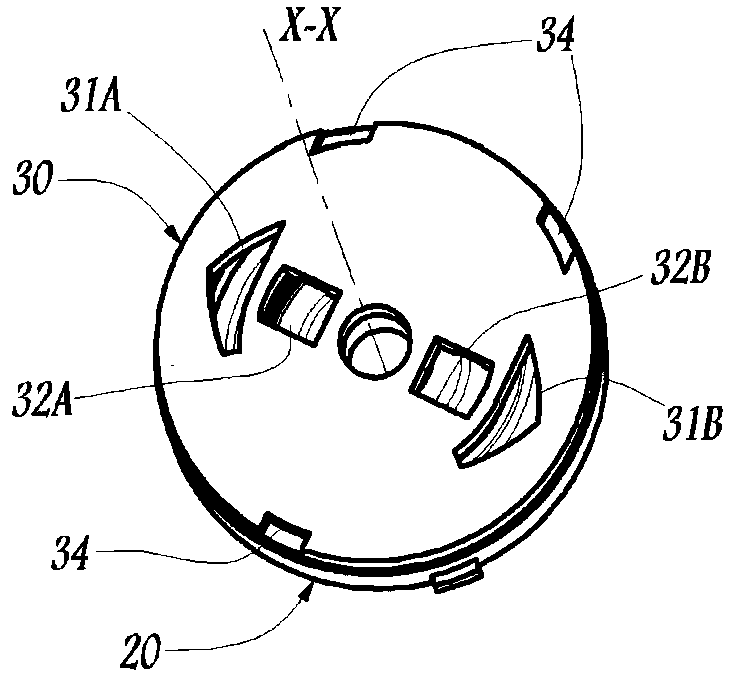

[0027] Housed inside the housing 2 is a core body 10 having an overall cylindrical shape around the axis X-X, with a circular base. The core body 10 defines a cold water introduction duct 11A and a hot water introduction duct 11B over its entire length, ie along the axis X-X direction. The core body 10 also defines, just on its upper part, a cold water return conduit 12A and a hot water return conduit 12B, which open at their lower end into a mixing chamber 13 centered on the axis X-X. The ducts 11A, 11B, 12A and 12B are positioned angularly and radially relative to the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com