Liquid foam making apparatus

A foam and liquid technology, applied in the field of liquid foam production equipment, can solve the problems of increased safety risk, liquid leakage risk, inconvenient use, etc., and achieve the effect of simple and reasonable structure, easy cleaning and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

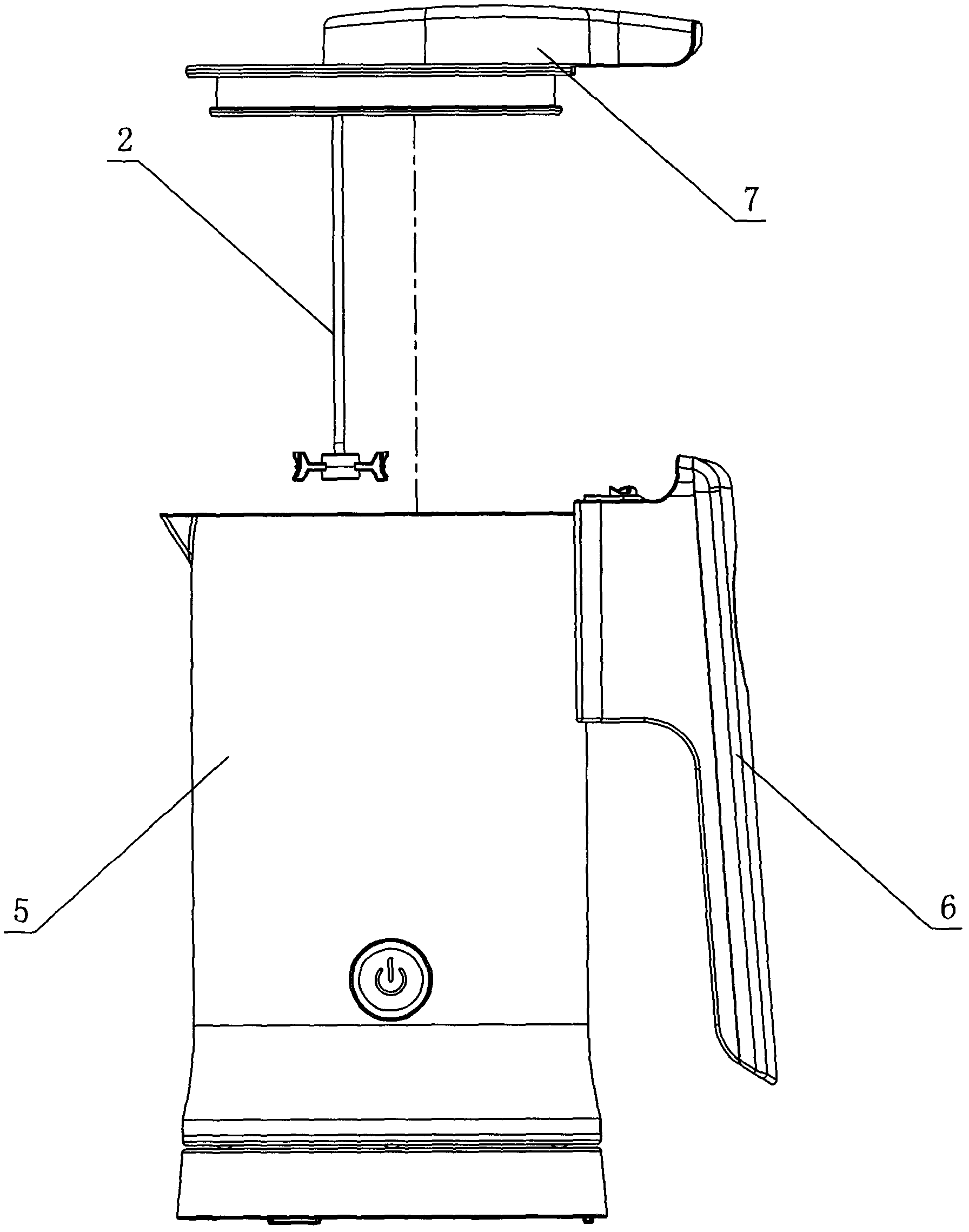

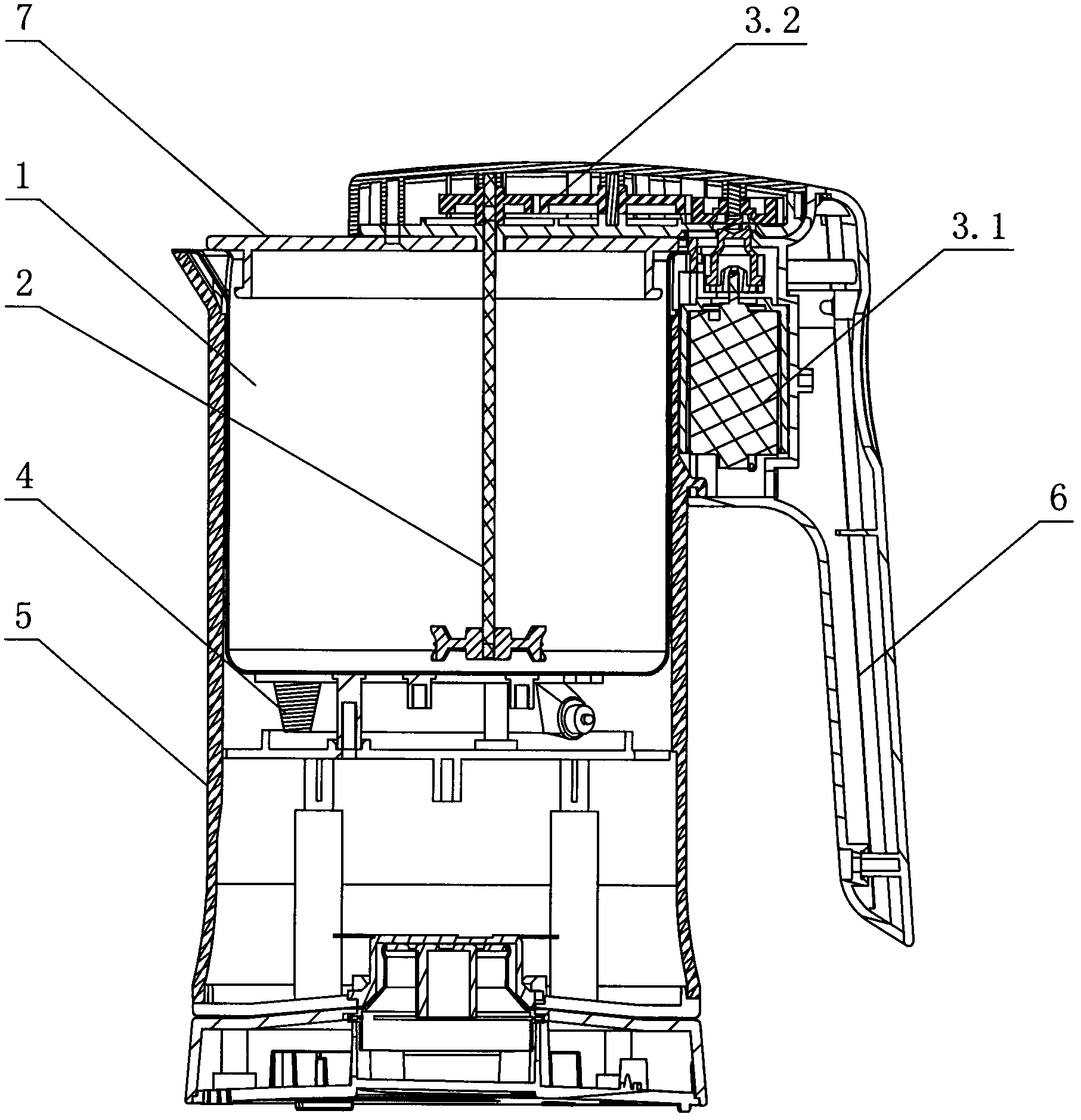

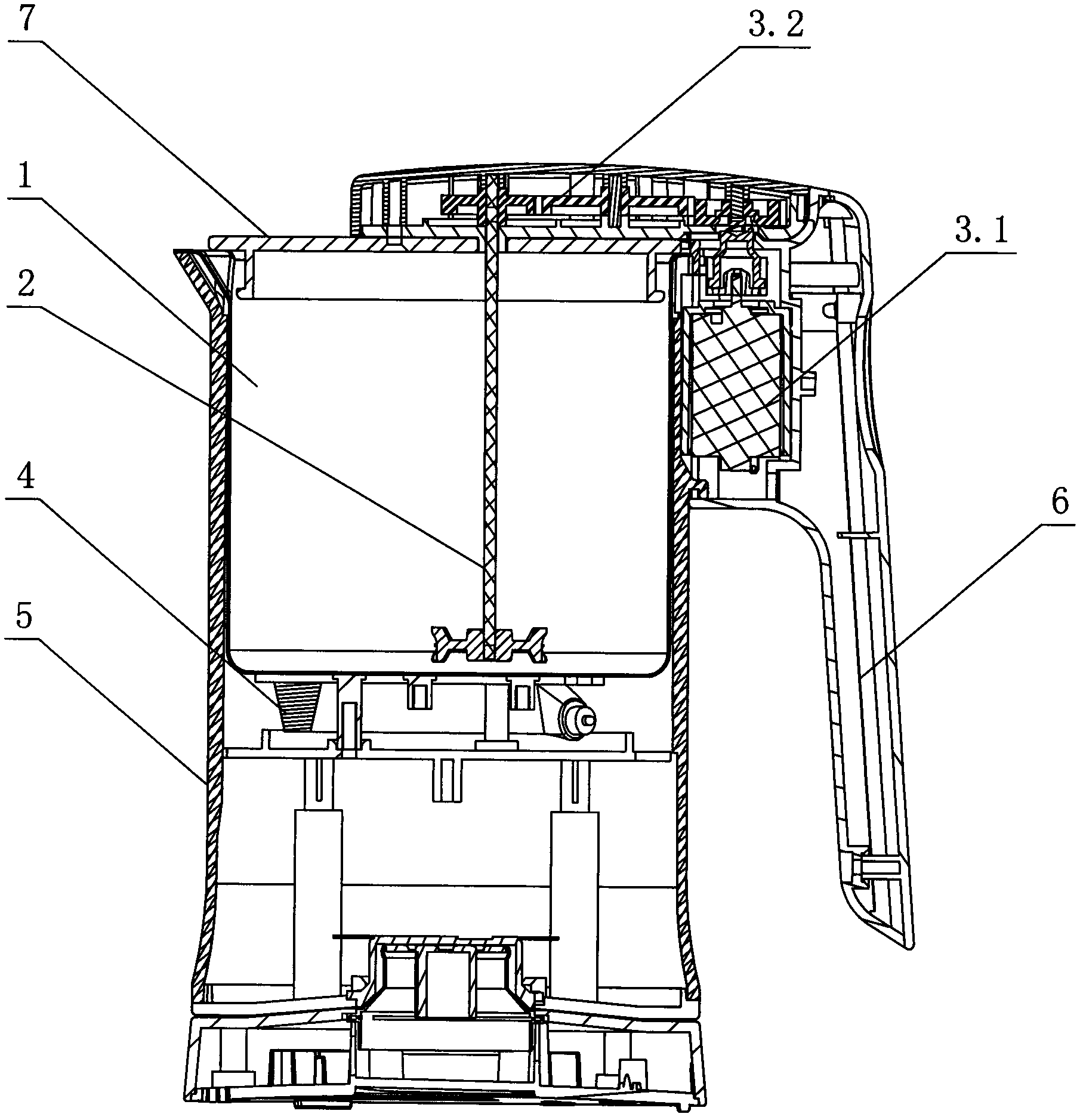

[0015] see Figure 1-Figure 2 , this liquid foam making utensil comprises cup body 5, inner cup 1, cup cover 7, stirring mechanism and driving device, and driving device is made up of motor 3.1 and transmission mechanism 3.2, and transmission mechanism is arranged in cup cover 7, and the stirring mechanism of stirring mechanism The upper end of the shaft 2 is connected to the transmission mechanism, the lower end of the stirring shaft 2 is provided with blades and extends into the lower part of the inner cup 1; the upper side of the cup body 5 is provided with a handle 6, and the motor 3.1 is arranged inside the handle 6, and the motor 3.1 and the transmission mechanism are separable , which is provided with a touch switch. The transmission mechanism is gear transmission, belt transmission or worm gear transmission. The inner cup 1 is an open cup with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com