Heat-push bending method for producing pipe fittings with equal diameters and equal wall thicknesses

A production method and a technology of equal wall thickness, which is applied in the field of hot push bending production of wall thickness pipe fittings, can solve the problems of easy concave deformation, poor appearance quality, and inability to take out the inner core at the two ports of the elbow, and achieves small size deviation, Beautiful appearance and the effect of improving the overall stress condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

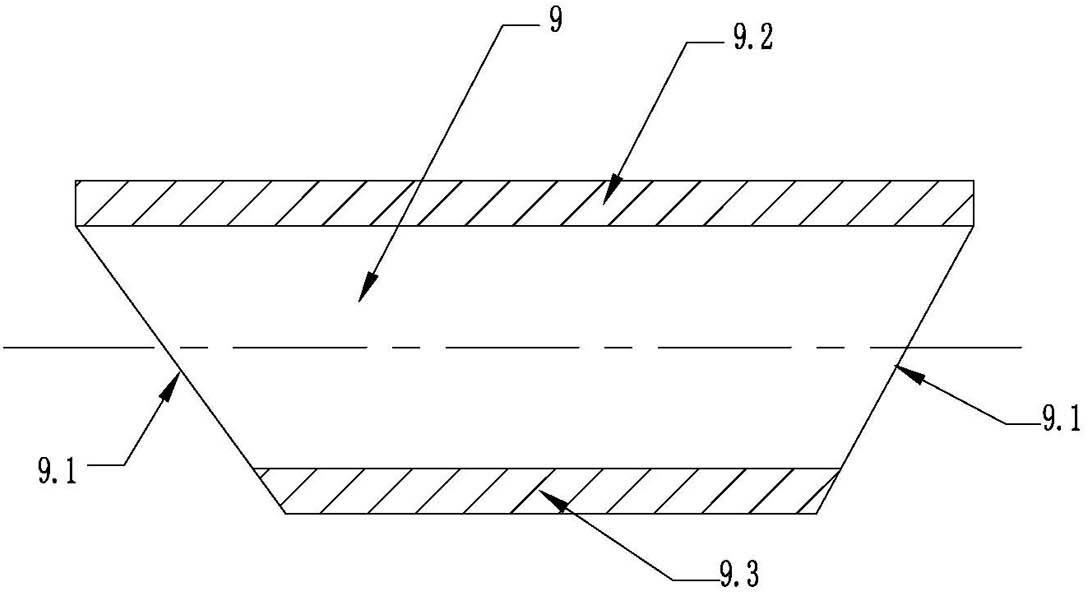

[0024] Example 1. Production of elbows with pipe fitting specifications of φ508*50, 1.5D

[0025] 1. Cut the elbow pipe fitting blank with a steel pipe with a specification of φ508*50, so that the two ends of the elbow pipe fitting blank are obliquely shaped, and the length of the long section of the elbow pipe fitting blank is the outer arc length of the finished elbow pipe fitting to be produced , The length of the short section of the elbow pipe fitting blank is the inner arc length of the finished elbow pipe fitting to be produced; the length of the long section is 1600mm, and the length of the short section is 900mm;

[0026] (2) Put the cut elbow pipe blank into the heating furnace, and heat the elbow pipe blank to 950°C;

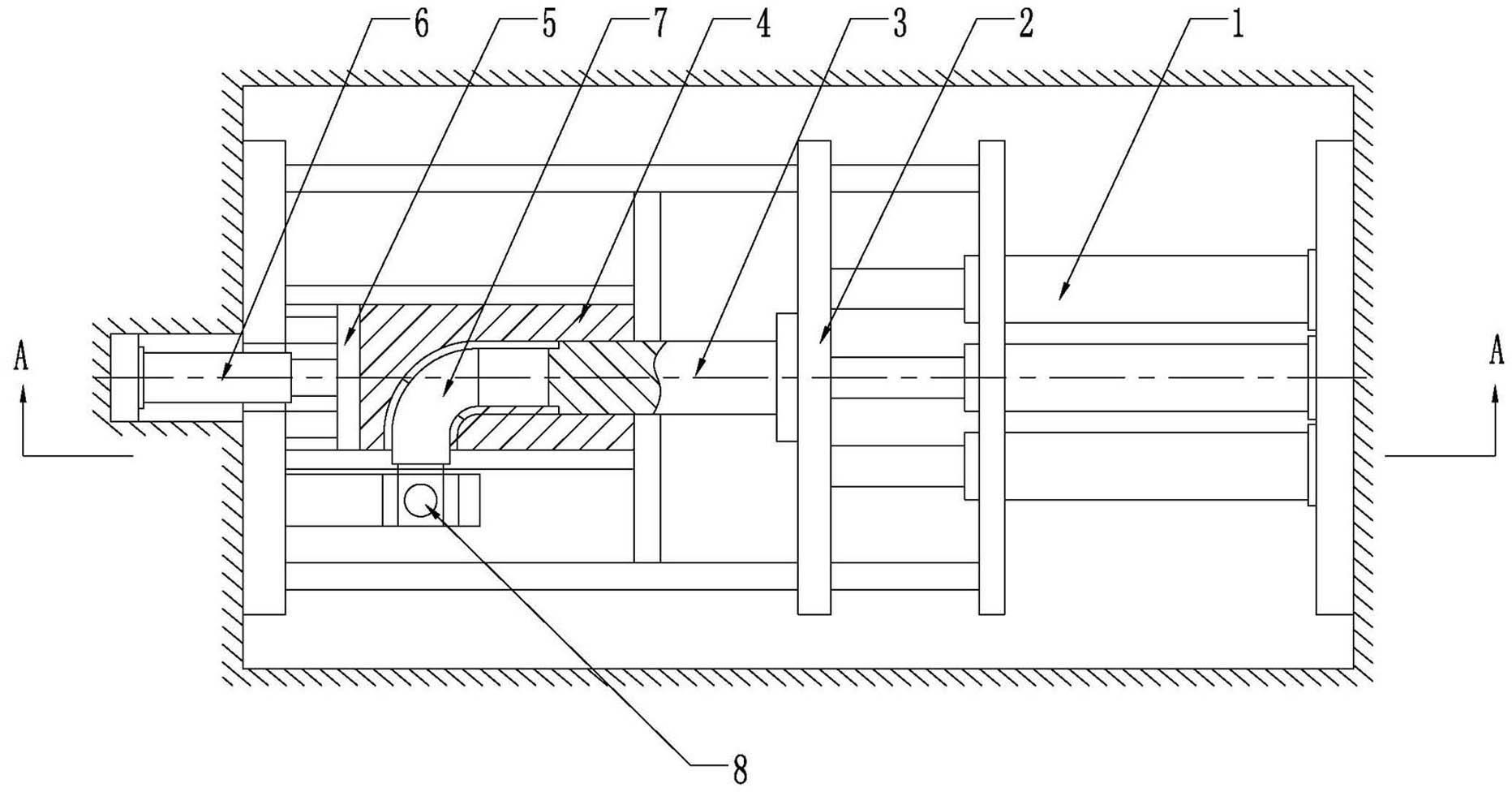

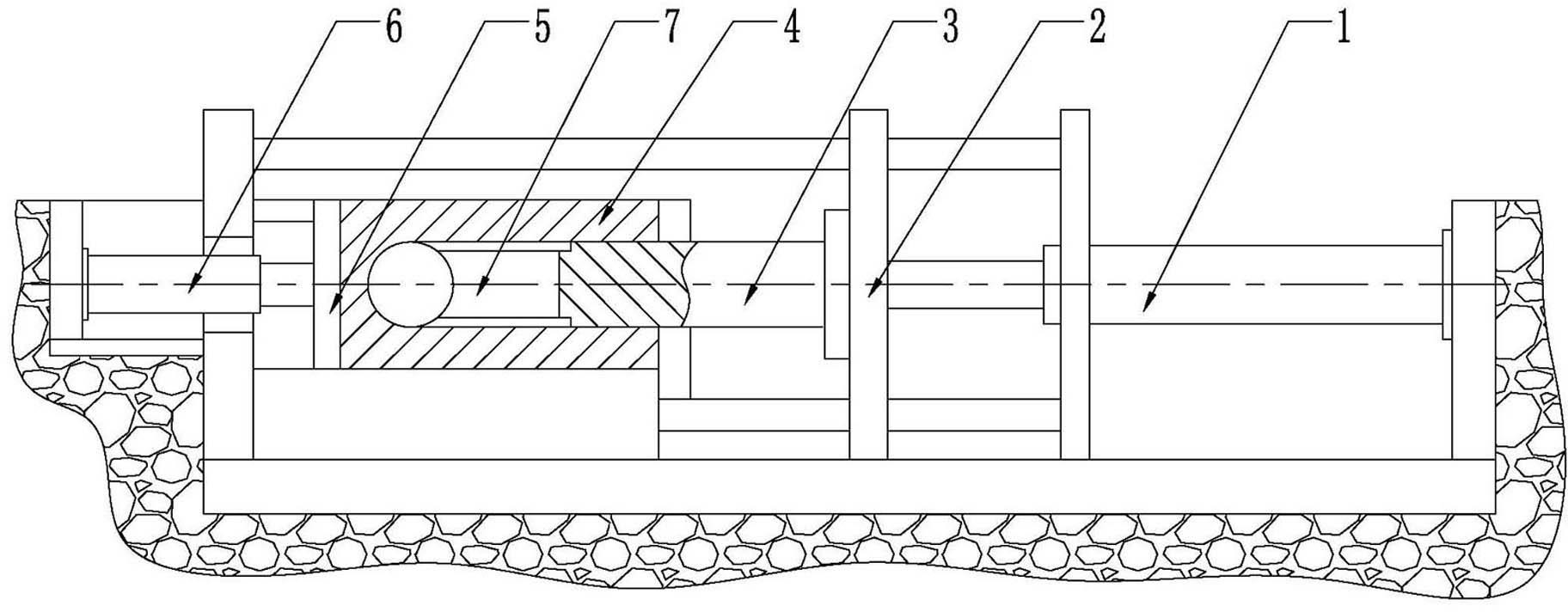

[0027] (3) Put the heated elbow pipe fitting blank into the hot push bending device of equal-diameter and equal-wall-thick pipe fittings to push the pipe fitting. Specifically, put the heated elbow pipe fitting blank into the combination mold 4 first,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com