Method for separating and purifying cordycepin by utilizing high-speed counter-current chromatography

A high-speed counter-current chromatography, separation and purification technology is applied in the field of producing cordycepin standard products by using high-speed counter-current chromatography separation and purification method, and achieves the effects of simple operation method, good peak separation effect, high cordycepin yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The practice and drugs used in the experiment are shown in Table 1

[0073] Table 1 Experimental drugs and reagents

[0074]

[0075] 1. Sample pretreatment

[0076] Take 900ml of the crude cordycepin extract, and centrifuge for 20min at a speed of 3500r / min. About 800ml of supernatant. Seal the collected supernatant and store it at low temperature for future use.

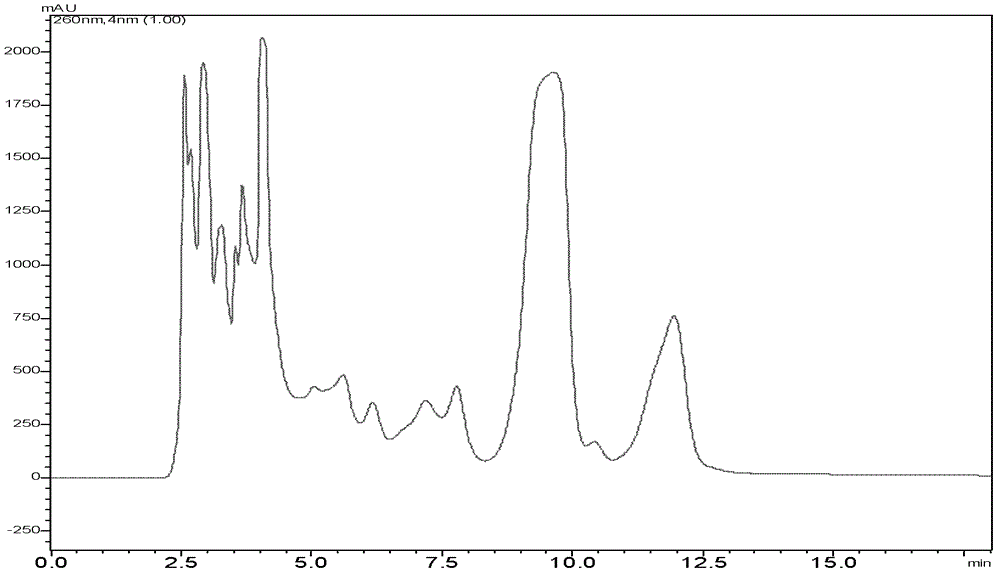

[0077] The content of cordycepin in the supernatant of the crude extract of cordycepin was determined by high performance liquid chromatography, the chromatographic conditions were: mobile phase: methanol: water=15:85 (V / V), detection wavelength: 260nm, Column temperature: room temperature, flow rate: 1ml / min, injection volume: 20μl, t R About 10min. Its chromatogram see figure 2 .

[0078] We can see from the chromatogram that the substance in the crude extract of cordycepin is very impurity, especially there are many impurity peaks in the front part of the high-performance liquid chromatogram, b...

Embodiment 2

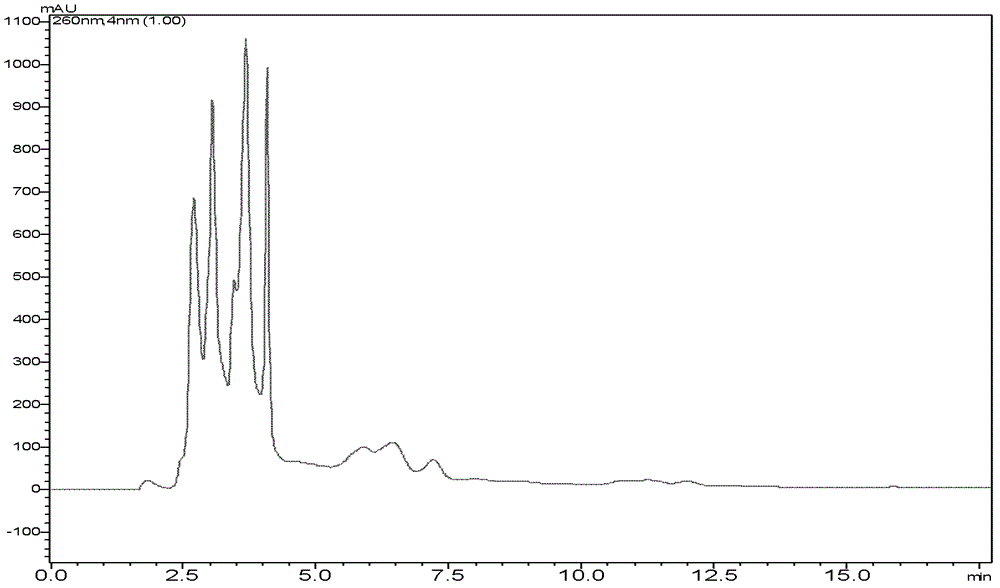

[0158] The difference from Example 1 is that the two-phase solvent system for isolating cordycepin is n-hexane: n-butanol: methanol: water=25:75:25:150, K=0.5, and the obtained mass percentage is 98.79 % pure cordycepin ( Figure 16 , t=9.81).

Embodiment 3

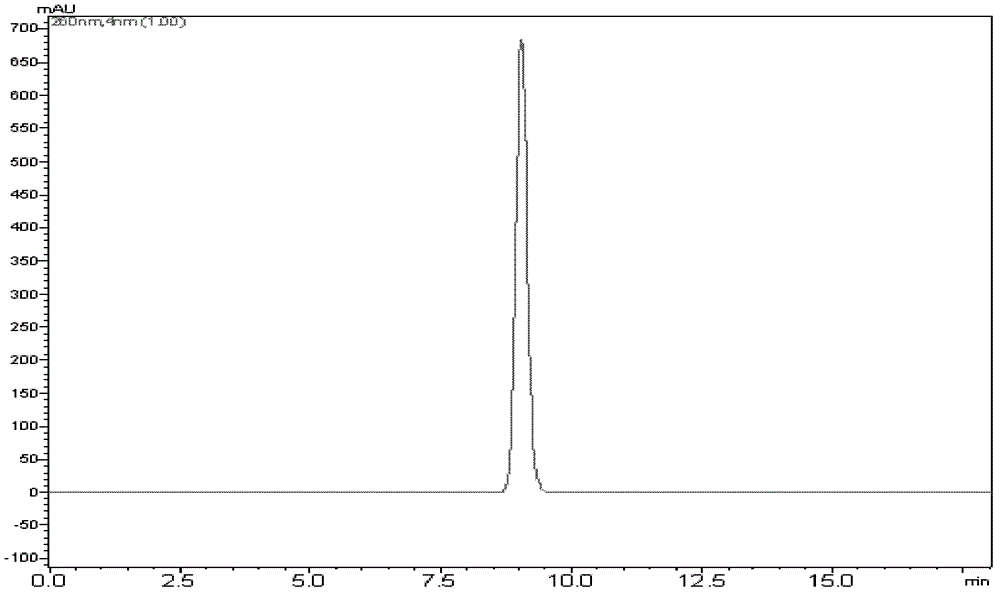

[0160] The difference from Example 1 is that the two-phase solvent system for separating cordycepin is n-hexane: n-butanol: methanol: water=25:70:28:145 (V / V), K=1.0, and the mass 99.85% pure cordycepin ( Figure 17 , t=9.79).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com