In-cylinder direction injection gasoline engine and control method thereof

A technology of in-cylinder direct injection and control method, which is applied in the direction of engine control, fuel injection control, electrical control, etc. It can solve the problems of increased hydrocarbon and soot emissions, increased NOx emissions, and poor fuel atomization, etc., to reduce Air intake density, reducing throttling loss, and avoiding the effect of wet wall phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

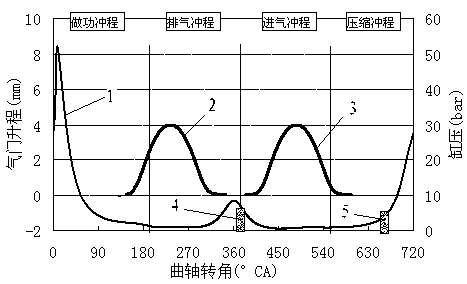

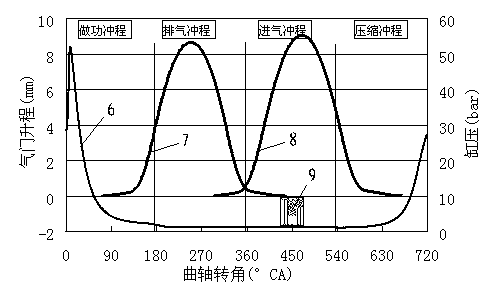

[0019] In this embodiment, the in-cylinder direct-injection gasoline engine includes an electronic control unit, a valve mechanism, and an in-cylinder fuel injector, and the electronic control unit is connected to the fuel injector and the engine control system respectively. Each cylinder block is provided with an intake valve consisting of a first intake valve and a second intake valve, and an exhaust valve consisting of a first exhaust valve and a second exhaust valve. Camshaft control, the exhaust valve is controlled by the exhaust camshaft, the first intake valve and the second intake valve are respectively controlled by two cams with different lift ranges arranged on the intake camshaft, so The first exhaust valve and the second exhaust valve are respectively controlled by two cams with different lift ranges arranged on the exhaust camshaft, and the electronic control unit controls the intake camshaft and the exhaust camshaft through the transmission mechanism. The cams o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com