Multi-terminal heating and cooling control method based on total current control

A refrigeration control, multi-terminal technology, applied in the direction of program control, computer control, general control system, etc., can solve problems such as blindness, insecurity and inconvenience, and excessive current load, so as to ensure safety and avoid unsafe Events, Guaranteed Operational Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

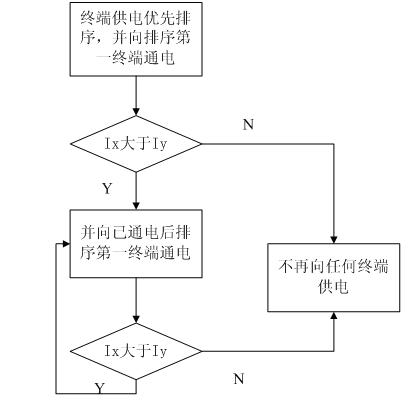

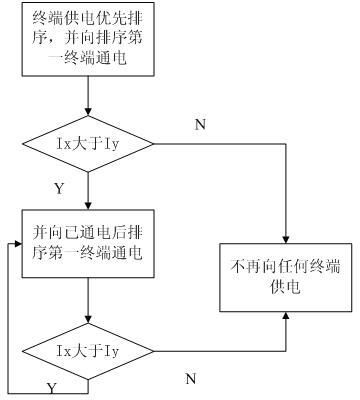

Image

Examples

Embodiment

[0012] The maximum current allowed by the default incoming line is I=40 amperes, and the working currents of heating terminals A, B, C, D, E, F, G, H, and J are respectively I a =10, I b =13, I c =8, I d =11, I e =12, I f =13, I g =13, I h =12, I j =12 amps, , The heating period of a day is divided into six periods, namely 5:30~8:00, 8:00~11:30, 11:30~13:30, 13:30~17:30, 17:30~21:30 , 21:30~5:30. Now take the 5:30~8:00 heating period as an example, the system setting is shown in Figure (1). When the system is working, it first determines that the current date is Tuesday, and then determines that it is currently in the 5:30~8:00 heating period and the period The priority numbers corresponding to all heating terminals in the interior are A-5, B-2, C-6, D-4, E-1, F-3, G-7, H-9, J-8, and the central processing The device sends a power-on command to the sorting No. 1 terminal E, and the central processing unit detects that the incoming bus current=I e =12 amperes b +I ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com