Bonding bolt mechanism for fixing automotive wiring harness bonding terminal

A technology for terminal fixing and automotive wiring harness, which is applied in the direction of screws, connecting components, mechanical equipment, etc., can solve the problems of poor reliability, time-consuming and labor-intensive, etc., and achieve the effect of solving time-consuming and labor-intensive work, ensuring work reliability and simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

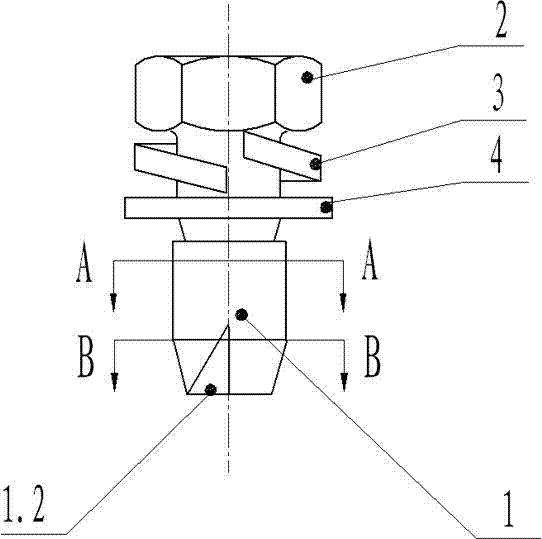

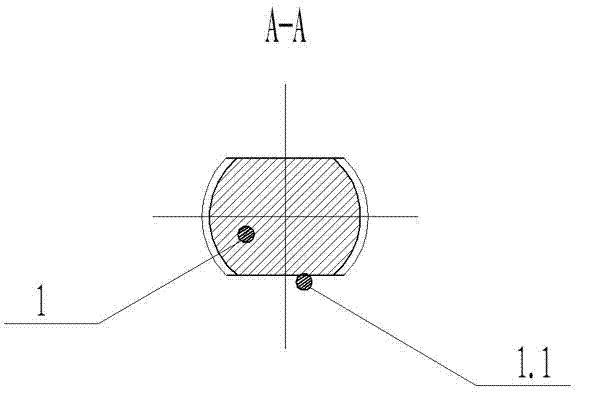

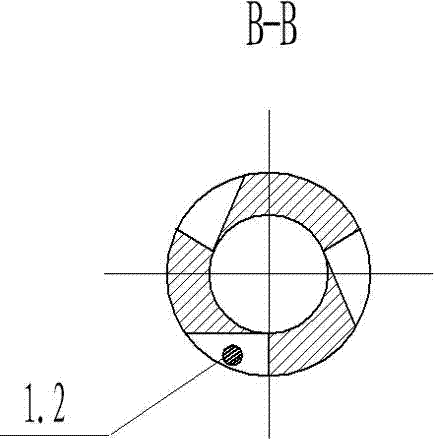

[0015] see figure 1 , the grounding bolt mechanism used for fixing the grounding terminal of the automobile wiring harness includes a grounding bolt, the upper part of the grounding bolt is a nut 2, the middle part is a shaft, and the lower part is a stud 1, and the middle shaft is covered with a spring washer 3 Peace washers4. The axially symmetrical sides of the stud 1 are flattened planes 1.1, see figure 2 , the diameter of the stud 1 is 12mm, and the width between the flattened planes on both sides of the stud is 10mm; the lower end of the stud is an inverted cone, and three oblique The mouth groove 1.2 and the oblique groove 1.2 are axial grooves, and are trumpet-shaped grooves with a small upper part and a larger lower part, see image 3 , three oblique slots 1.2 form a reamer shape.

[0016] see Figure 4 , when assembling, first se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com