Umbrella water remover and hydro-extracting mechanism thereof

A dewatering machine and water throwing technology, which is applied to the types of dry products, dry solid materials, walking sticks, etc., can solve the problems of affecting dewatering efficiency, unsafe, wasting time, etc., and achieve the effects of easy removal, reduced vibration and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention are described in detail below.

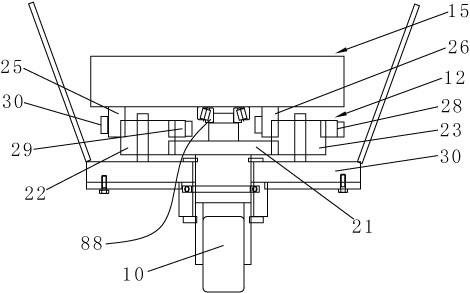

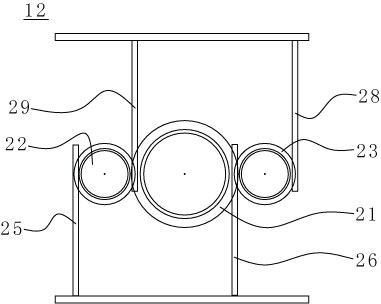

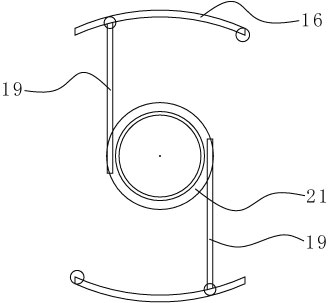

[0030] refer to figure 1 , figure 2 Shown, a kind of water throwing mechanism of the present invention is used for having main motor 82 (referring to Figure 7 as well as Figure 9 Shown) in the umbrella dewatering machine, the umbrella is clamped for water rejection, and the water rejection mechanism includes a long or circular support member 15 for supporting the umbrella, and a shaft connected to the output shaft of the main motor for The push-pull support device 12 that supports the support member 15, the two clamping end caps 16 that are arranged at both ends of the support member 15 and can be tightened equidistantly and reversely, the push-pull support device 12 and the clamp The holding end cover 16 is connected and the clamping end cover 16 can be tightened under the driving of the main motor, and then the supporting member 15 can be driven to rotate, and the clamp can be automatically pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com