Dual-layer collective liquid distributor with lateral line withdrawal function

A liquid distributor and side line extraction technology, which is applied in the field of liquid distributors and collecting liquid distributors, can solve the problems of large space height, achieve good effect, simple structure, and save space and height in the tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

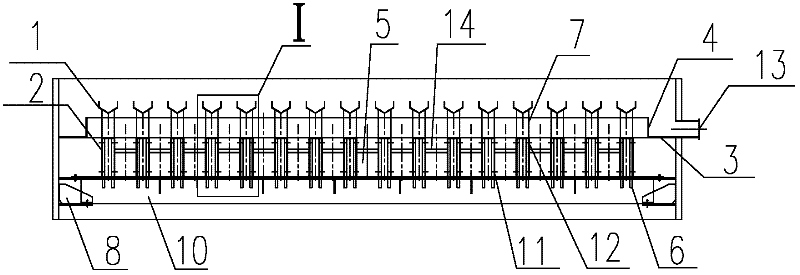

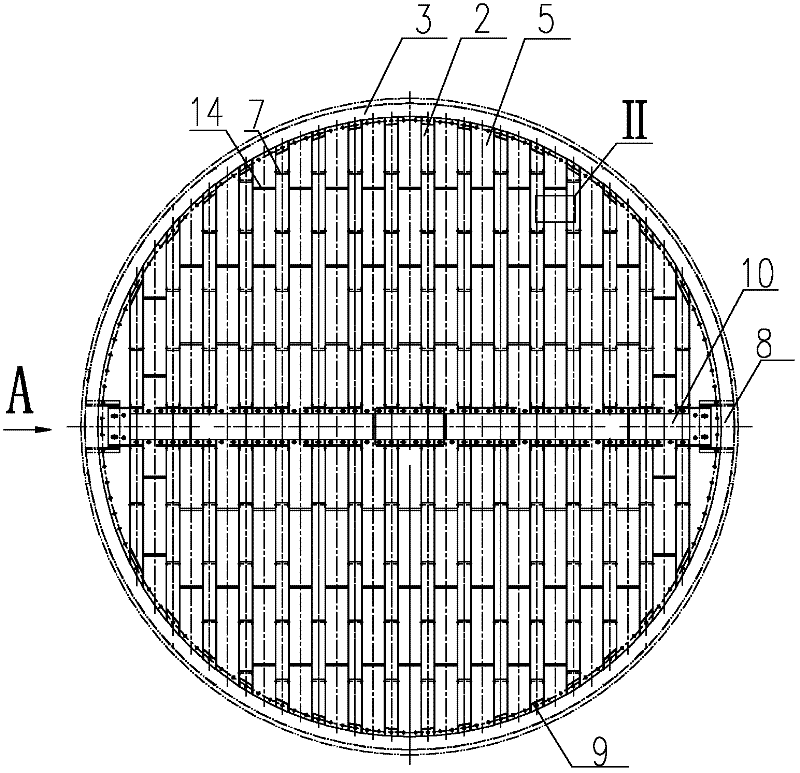

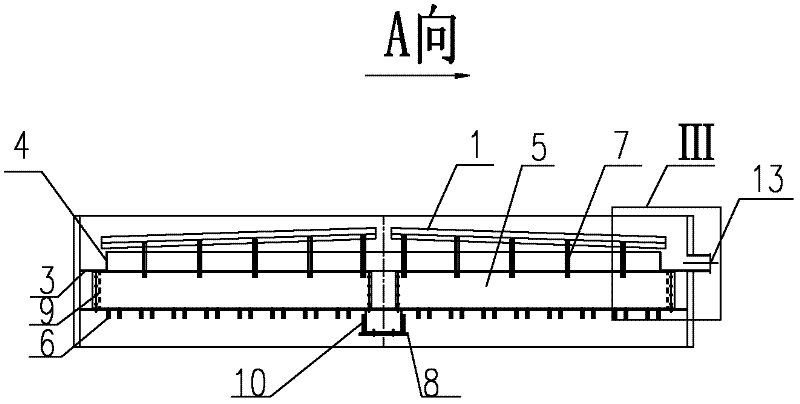

[0026] Such as Figure 1~6 As shown, the lifting cap 1 of the double-layer collecting liquid distributor with side line extraction is connected to the lifting cylinder 2 through the connecting plate 7, with the liquid collecting channel 10 as the central axis, the height of the connecting plate 7 is along the central axis of the tower wall The two sides are successively lowered to form an inclined lift cap 1, such as image 3 and Figure 6 As shown, the inclination direction of the air lift cap from high to low is the flow direction of the liquid, so that the liquid collected on the air lift cap 1 flows smoothly into the liquid collection ring 3; the air lift tube 2 can be a cylinder, a square tube, or a rectangular tube etc., the present embodiment is a rectangular inflator; the liquid collection ring 3 is welded to the tower wall, and the vertical ring 4 is welded on the liquid collection ring 3. The position of the side line extraction pipe 13 can be determined according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com