Ventilation system and method for subway equipment room

A ventilation system and equipment technology, applied in ventilation systems, air conditioning systems, mechanical equipment, etc., can solve problems such as poor comfort, reduce the scale of civil works, and reduce the height of space, achieve precise control of room air environment, optimize subway ventilation systems, reduce The effect of space height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

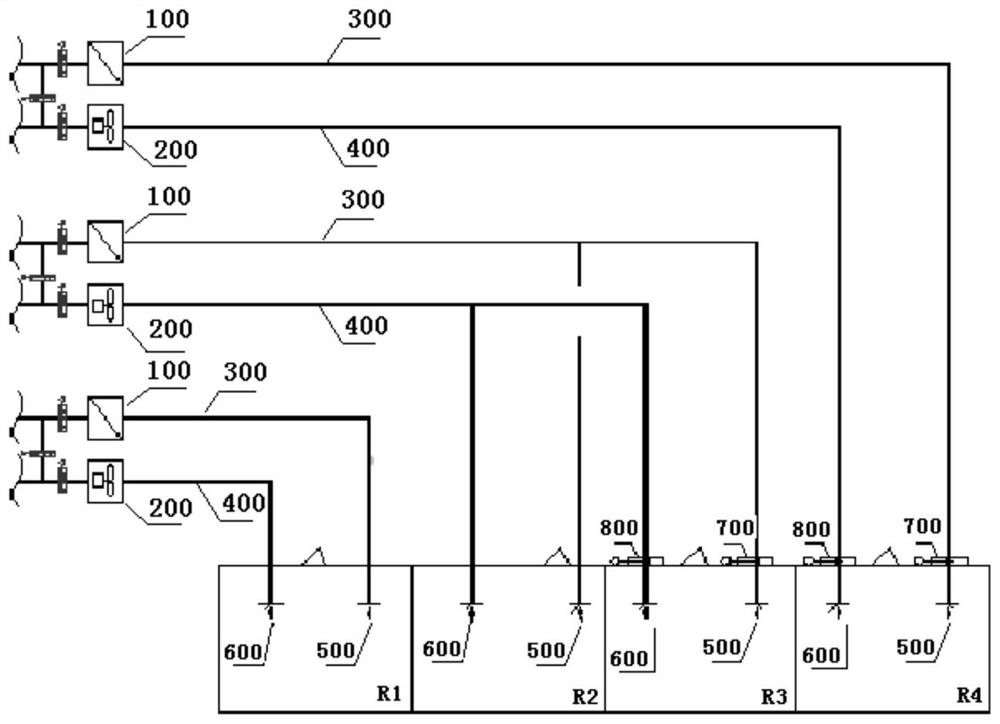

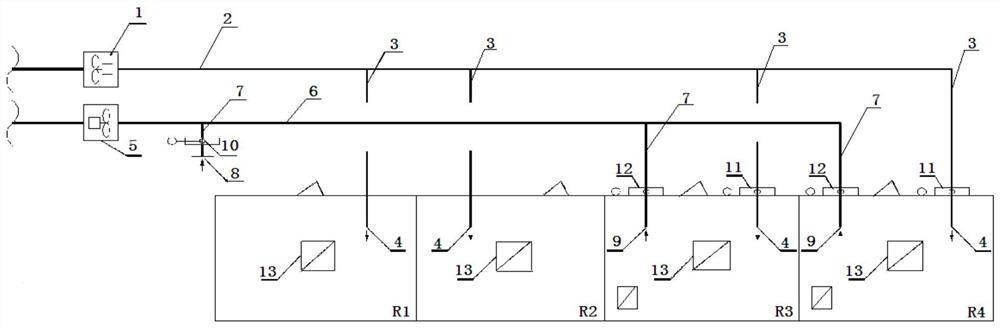

[0042] This embodiment provides a ventilation system for subway equipment rooms, such as figure 2 As shown, considering that there are many subway equipment rooms in the actual situation, it cannot be completely drawn in the figure, so four rooms represent four types of equipment rooms as an example, and R1 is the management room that runs for 18 hours (generally including : station master's room, conference room, police room, rest room, shift room, changing room, work area office, security inspection room, etc.); R2 is an equipment room that operates 24 hours without a gas fire extinguishing system, and the indoor design temperature is 27 ℃; R3 is an equipment room with a gas fire extinguishing system running for 24 hours, and the indoor design temperature is 27°C; R4 is an equipment room with a gas fire extinguishing system running for 24 hours, and the indoor design temperature is 36°C.

[0043] The ventilation system includes fresh fan 1, air supply main pipe 2, air suppl...

Embodiment 2

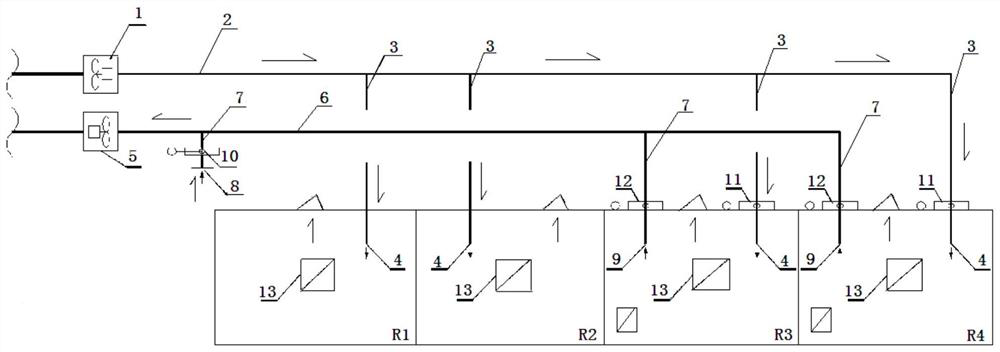

[0048] This embodiment discloses a ventilation method for subway equipment rooms, such as image 3 , Figure 4 As shown, the ventilation method is realized by the subway equipment room ventilation system provided in embodiment 1, and the method includes:

[0049] Under normal conditions, such as image 3 shown, including the following steps:

[0050] Step S101, turn on the fresh air fan, the exhaust fan, and the electric on-off valve.

[0051] The electronically controlled on-off valve can be realized by an electric smoke-proof fire damper and / or an electric air volume regulating valve, and the electrically-controlled on-off valve is installed at the air supply branch pipes and the air exhaust of the spare room R3 and R4 of the subway spare room R3 and R4 provided with a gas fire extinguishing system. The branch pipes and the centralized air outlet of the corridor are respectively the air supply electric control on-off valve, the exhaust air electric control on-off valve an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com