Lifting device for coke furnace cover

A coke oven and furnace cover technology, applied in coke oven, coke oven heating, coke oven parts, etc., can solve the problems of temperature measurement equipment and other equipment interference on the furnace roof, and achieve stable posture, low height, and large lift The effect of the itinerary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

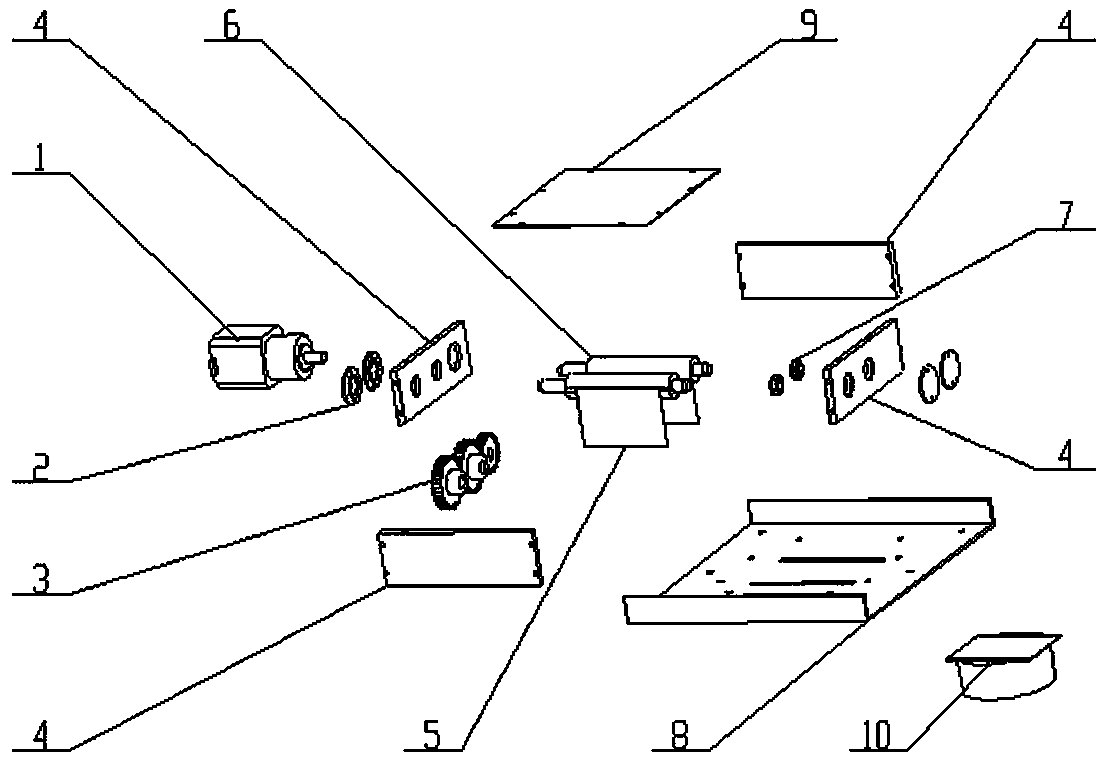

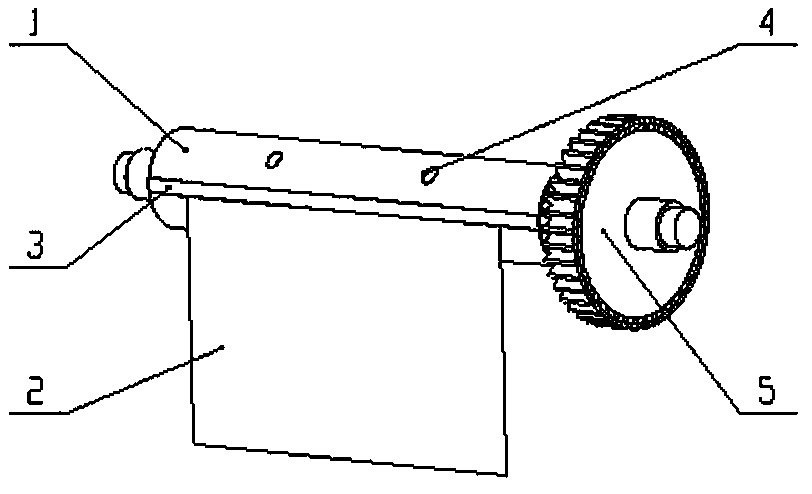

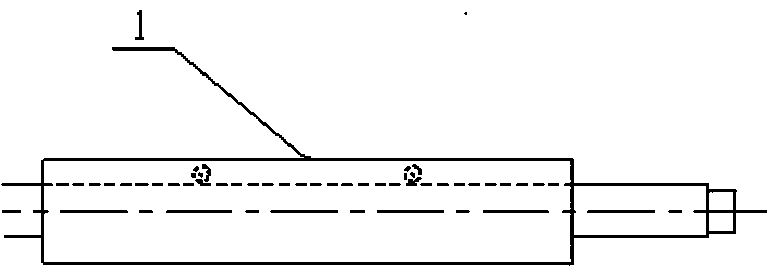

[0032] Such as figure 1 , the coke oven cover lifting device is mainly composed of a servo motor 1, including a bearing end cover 2, a cylindrical spur gear 3, a frame 4, a lifting steel belt 5, a lifting spindle 6, a bearing 7, a lower bottom plate 8, an upper cover plate 9 and an electromagnetic Iron 10 Composition. The two hoisting spindles in the hoist are arranged in parallel. During the operation, the hoisting spindles wind the steel belt at the same time, driving the electromagnet or the combination of the electromagnet and the furnace cover to move up and down. During the working process of the hoist, the spatial position of each part of the hoist will not change, and will not interfere with other equipment.

[0033] Such as figure 1 as well as Figure 6 As shown, the box body of the hoist is divided into two parts, the frame and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com