Semiautomatic single-screen multicolor silk screen printing device

A multi-color printing, semi-automatic technology, used in screen printing machines, printing, printing machines, etc., can solve the problems of low production efficiency, only one color can be printed at a time, and increased screen production costs, so as to improve production efficiency. , The effect of saving production costs and shortening printing man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

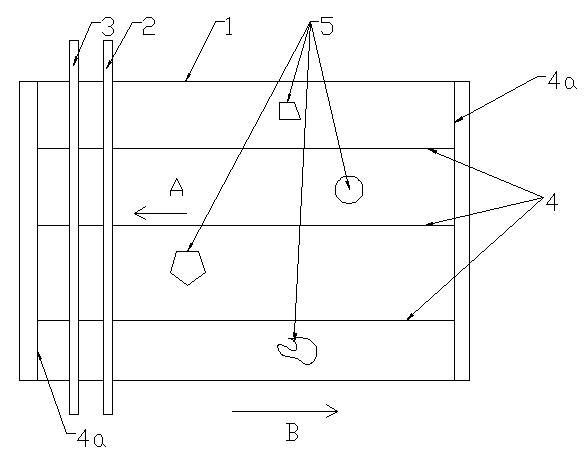

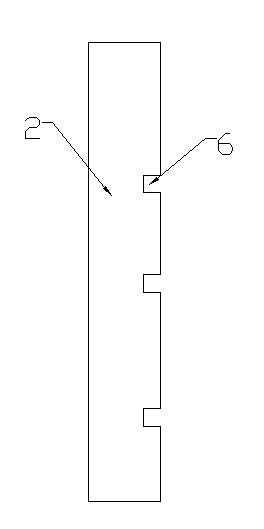

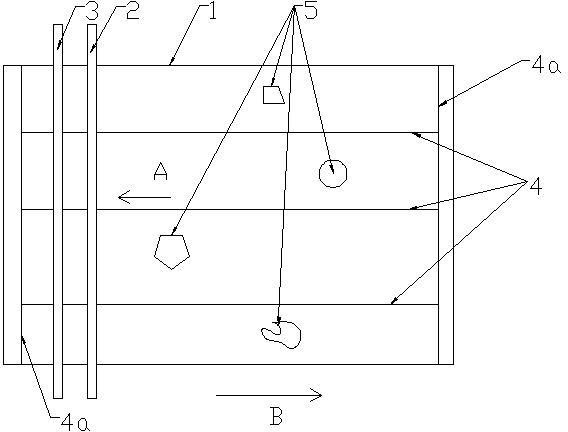

[0017] Such as figure 1 , figure 2 As shown, the semi-automatic screen single-screen multi-color printing device of the present invention includes a screen plate 1, a doctor blade 2, an ink return blade 3, and spacers 4, 4a.

[0018] In the screen plate 1, three spacers 4 are set in parallel in the printing direction, and the three spacers are set at a certain distance, and the screen plate 1 is divided into 4 areas, and inks of different colors are poured into the 4 areas, which can be printed separately 5 color products into 4 colors of graphic parts. The separation bar 4 is set to isolate the colors in different regions, and the colors will not be mixed, so as to ensure the purity of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com