Battery mounting structure of electric vehicle

An installation structure, a technology for electric vehicles, applied in vehicle components, rider drive, transportation and packaging, etc., can solve problems such as increased manufacturing cost, falling off, narrow space, etc., to facilitate repair and maintenance, reduce longitudinal height, reduce The effect of taking up space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

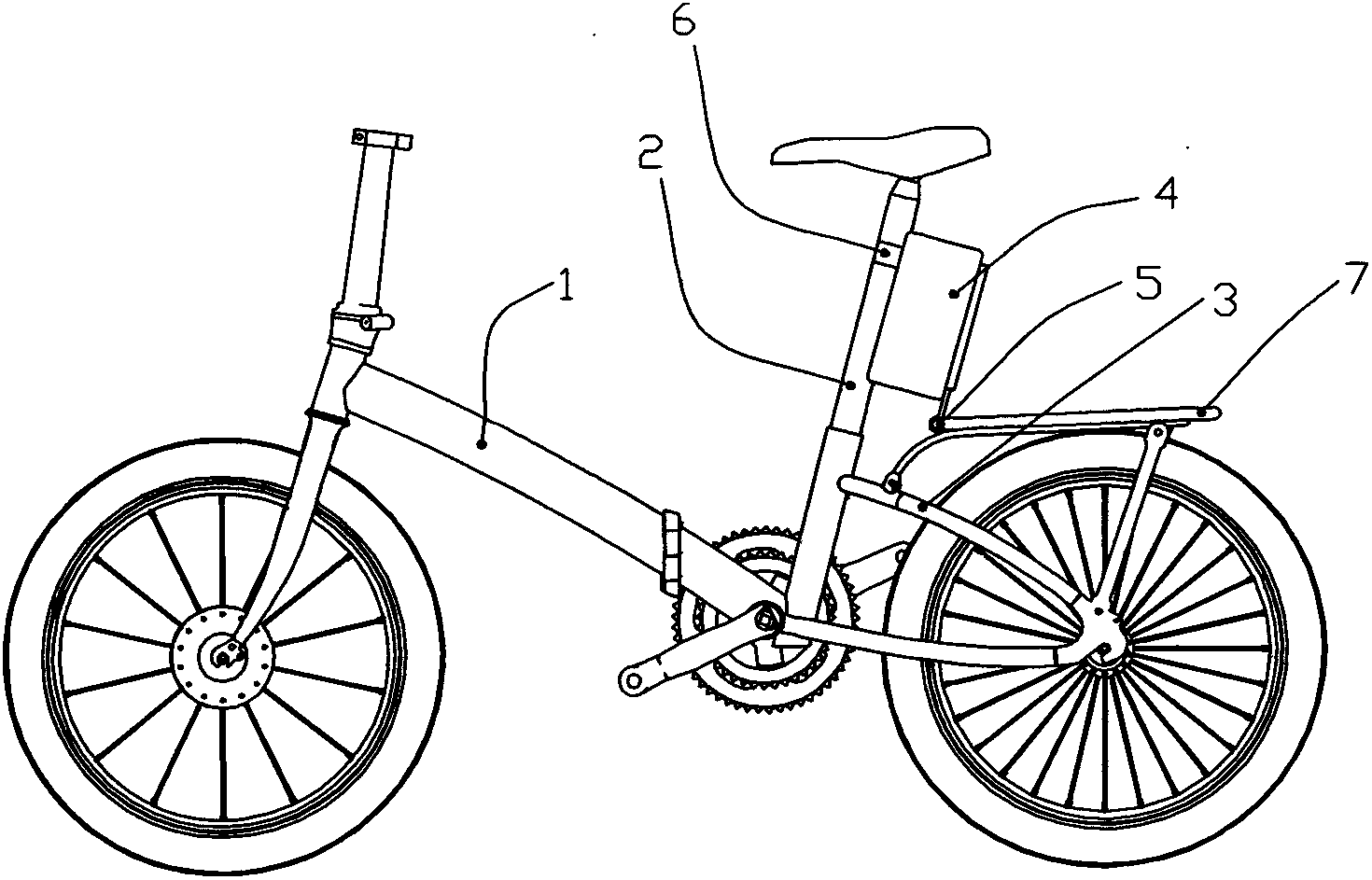

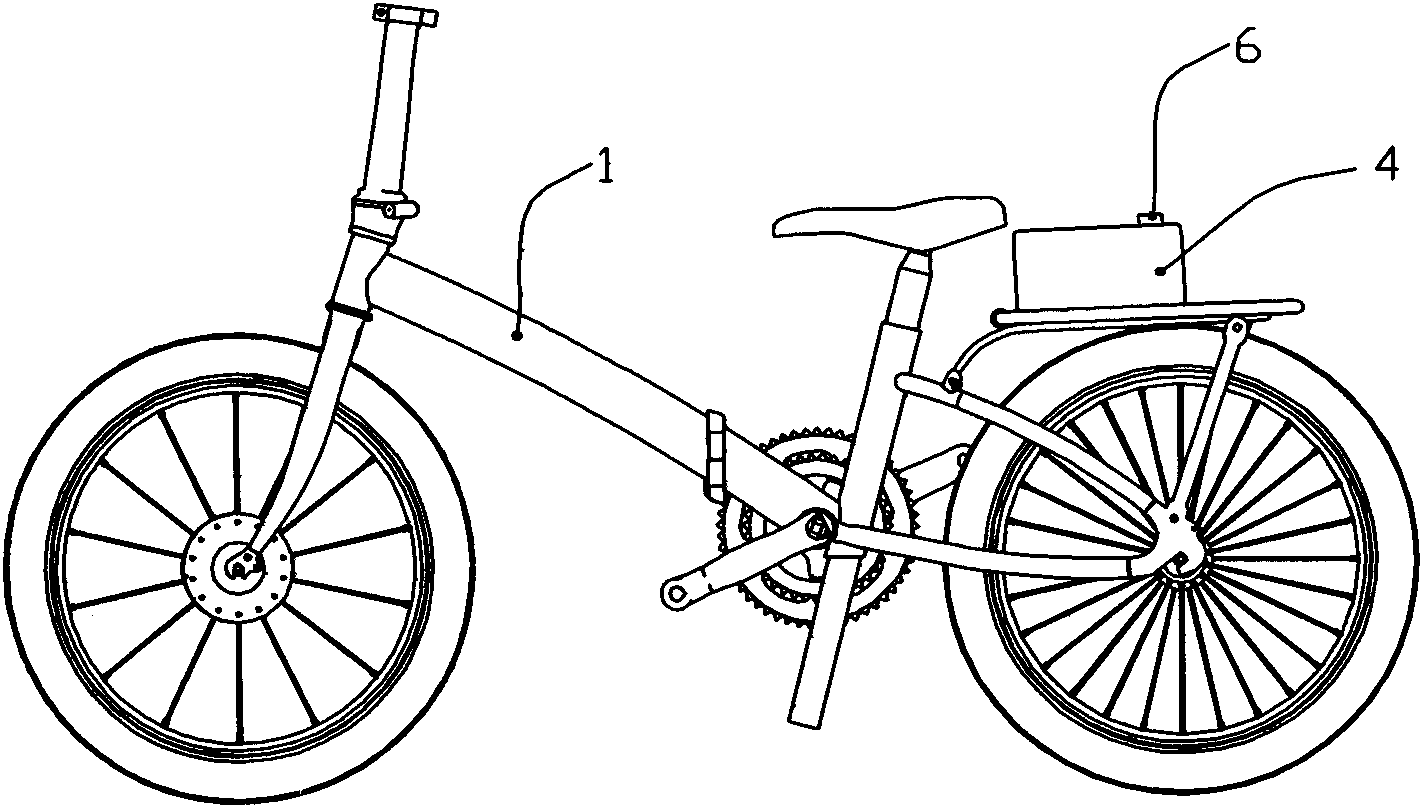

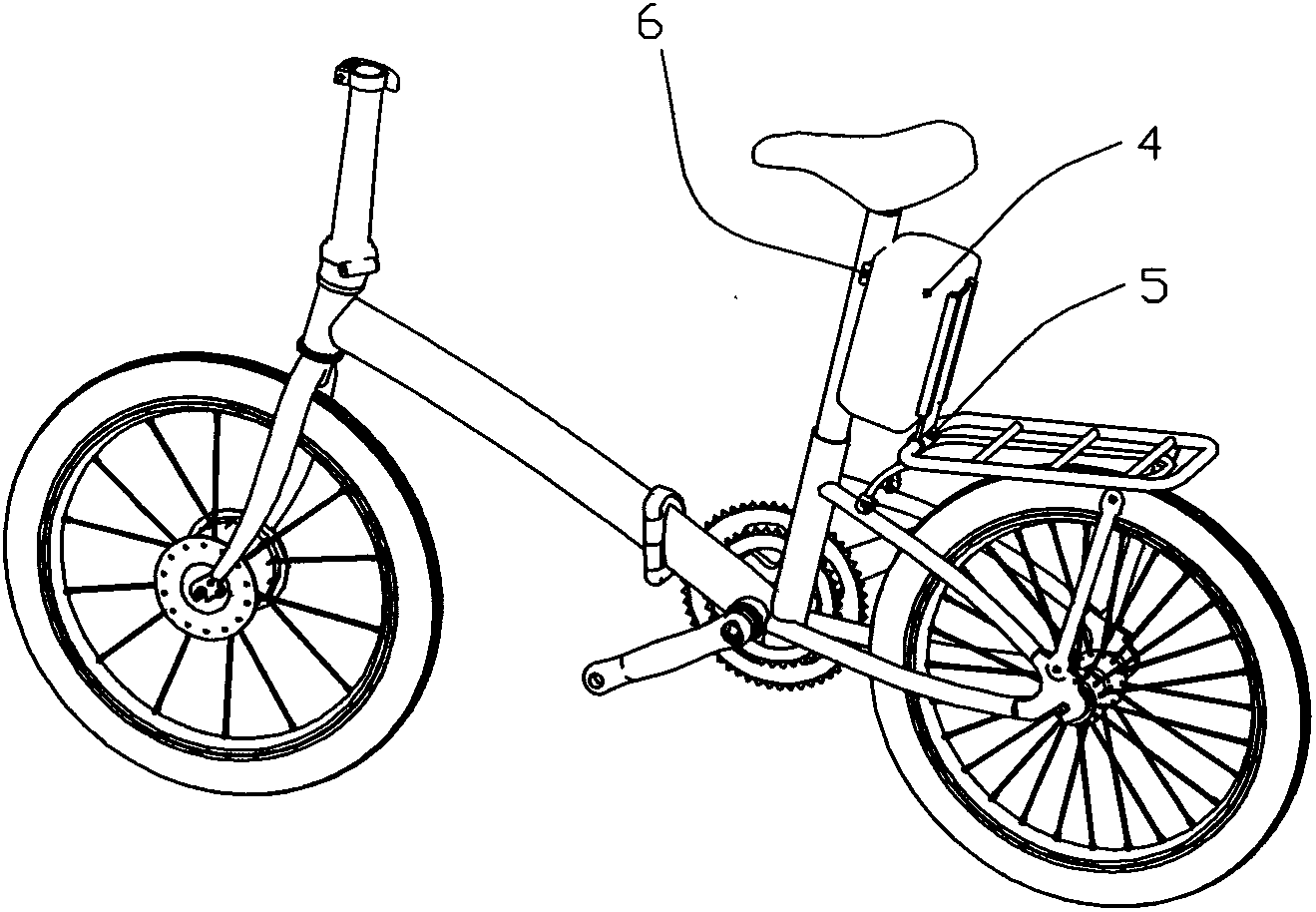

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

[0036] Electric vehicle comprises vehicle frame 1, front tube, front fork, seat tube 2, rear fork 3, front wheel, rear wheel, electric motor and battery, and battery installation structure disclosed by the present invention comprises a seat body 4 that accommodates battery, can adopt battery Pack the batteries in the box and put them into the base 4. The battery can be directly loaded into the base 4. In a word, the battery can be disassembled in the base 4 at will for replacement, repair and maintenance. One end of the base 4 is provided with The pivoting part 5 is rotatably connected to the supporting member provided on the electric vehicle.

[0037] Such as Figure 1-6 As shown, the rear fork 3 of the electric vehicle is provided with a bracket supporting the pivoting portion 5, the bracket is the support member, the pivoting portion 5 is arranged on the bracket, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com