A test method for plastic composite pipe with steel mesh skeleton

A technology for composite pipes and testing methods, which is applied in the direction of applying stable tension/pressure to test material strength, measuring devices, and analyzing materials, and can solve problems such as failure to perform composite layer pressure testing, waste of electric heating pipe fittings, and unstable sealing performance. , to achieve ideal test results, easy operation and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for testing the bonding strength of the outer bonding resin layer of a steel mesh skeleton plastic composite pipe, comprising the following steps:

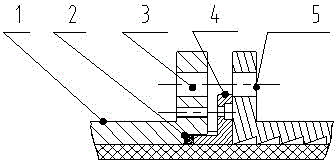

[0026] (1) Prepare a test fixture consisting of fixture base 1, rubber seal 2, connecting bolt 3, sealing pressure plate 4, fastening jaw 5, sealing pressure plate fastening screw 7, and end support block 10. The fastening jaw 5 There are serrated claws on the inner side.

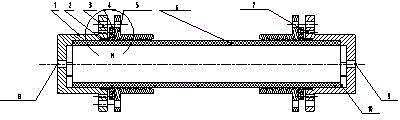

[0027] (2) Install the test fixture prepared in step (1) on both ends of the pressure test pipe to be tested, and 5 sets of fastening claws are stuck on the outer circumference of the pressure test pipe end. The fixture base 1 is sealed by fastening claws 5 and rubber seals. 2. The sealing pressure plate 4 is installed on the pipe end of the pressure test pipe 6, the rubber seal 2 is arranged between the fixture base 1 and the pressure test pipe 6, and the sealing pressure plate 4 is arranged between the fixture base 1 and the fastening claw 5, ...

Embodiment 2

[0030] A test fixture for the bonding strength of the outer bonding resin layer of the steel mesh skeleton plastic composite pipe, which consists of a fixture base 1, a rubber seal 2, a connecting bolt 3, a sealing pressure plate 4, a fastening claw 5, and a sealing pressure plate fastening screw 7. The end surface support block 10 is installed and composed of 5 sets of fastening claws that are stuck on the outer circumference of the pressure test pipe end. The fixture base 1 is installed on the pressure test pipe 6 through the fastening claws 5, rubber seal 2, and sealing pressure plate 4. The rubber seal 2 is set between the fixture base 1 and the pressure test pipe 6, the sealing plate 4 is set between the fixture base 1 and the fastening jaw 5, and the rubber seal 2 is squeezed between the fixture base and the pressure test pipe Between it and the sealing pressure plate, the fastening claw 5 is connected and fixed to the fixture base 1 by fastening bolts. The clamp base 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com