Steel tube end plate welding machine

A welding machine and steel pipe technology, applied in the field of machine tools, can solve the problems of high processing cost, low welding quality, low welding qualification rate, etc., and achieve the effects of improving welding processing efficiency, reducing welding processing cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

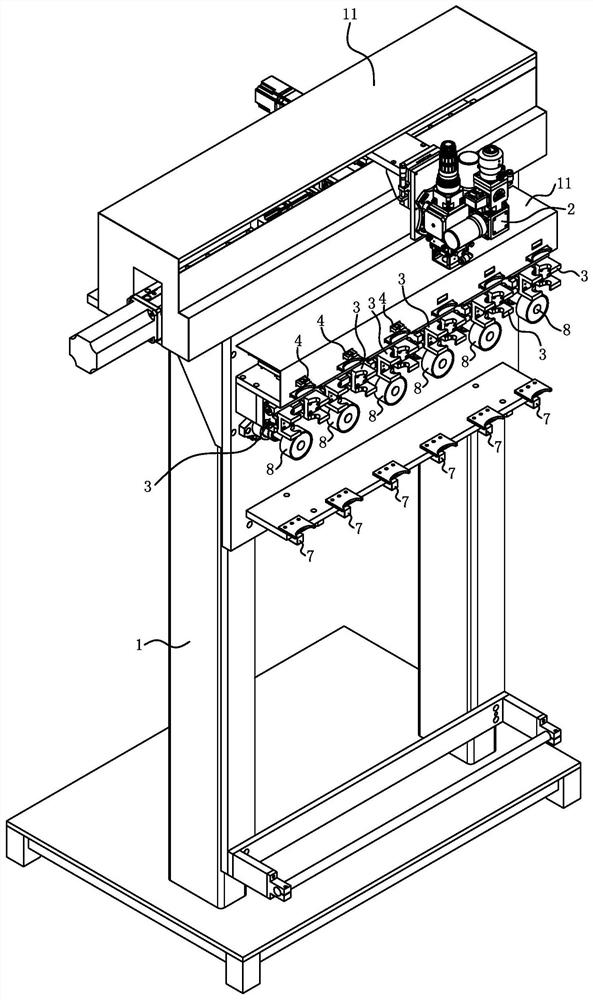

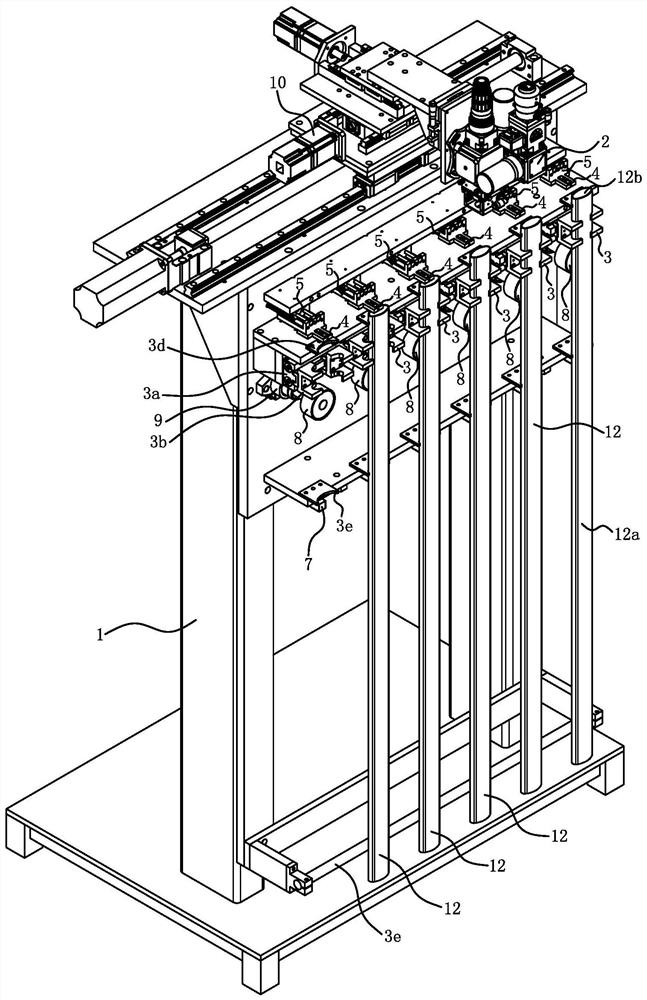

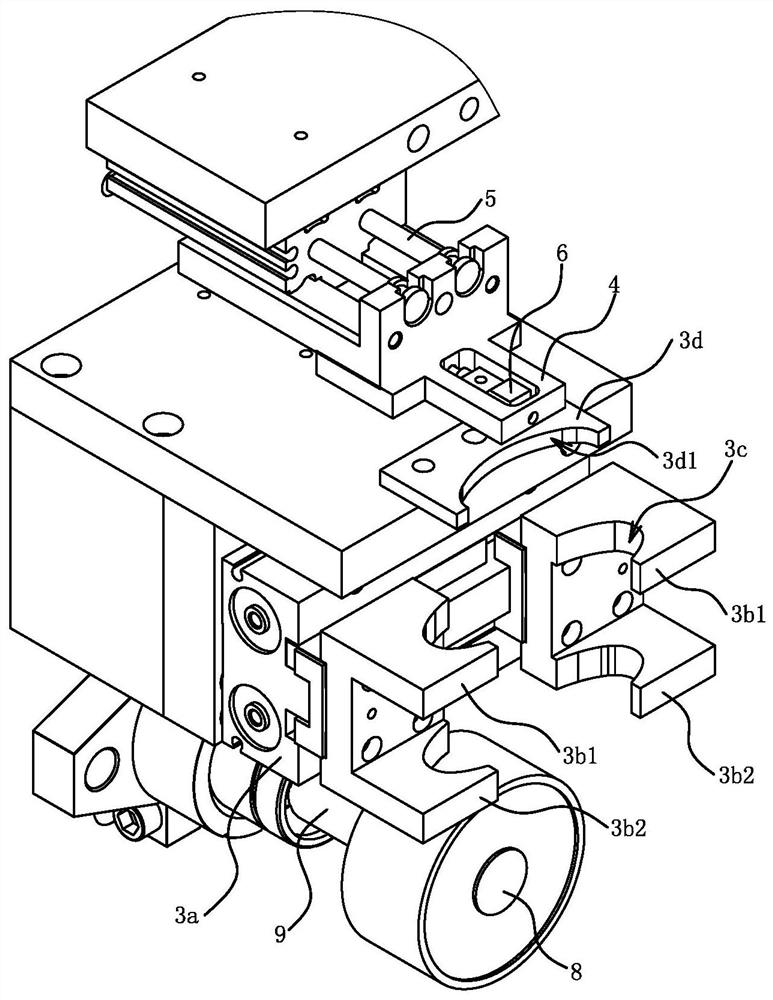

[0024] Embodiment one: if Figure 1 to Figure 4 As shown, a steel pipe end plate welding machine includes a frame 1 , a set of welding operation components 2 , multiple sets of clamping and positioning components 3 and a plurality of top surface positioning backers 4 .

[0025] The steel pipe 12 includes a pipe body 12a and an end plate 12b. The steel pipe end plate welding machine clamps and positions the pipe body 12a first, and then welds the end plate 12b to the pipe body 12a. The number of clamping and positioning components 3 is the same as the number of top positioning backers 4, and the clamping and positioning components 3 and the top positioning backers 4 are set in one-to-one correspondence, thus forming a plurality of welding stations, and the plurality of welding stations are relative to the frame 1 Arranged left and right; multiple processes such as installing the steel pipe 12, removing the steel pipe 12 and welding the steel pipe 12 can be carried out at the sa...

Embodiment 2

[0039] Embodiment 2: The structure and principle of this embodiment are basically the same as those of Embodiment 1. The basic similarities will not be described redundantly, and only the differences will be described. The difference lies in: the clamping and positioning assembly 3 includes a rear positioning backer And the front side pressure head, the rear side positioning backer is fixed on the frame 1, and the rear side positioning backer is provided with a positioning groove matching with the steel pipe profile, and the cylinder connected to the front side pressure head is installed on the frame 1. When the steel pipe is embedded in the positioning groove and the piston rod of the cylinder retracts, the front pressure head can press the steel pipe on the rear positioning backer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com