Automatic coiler feeding machine

A blanking machine and automatic technology, applied in the direction of pipe shearing device, shearing machine accessory device, shearing device, etc., can solve the problems of labor-intensive, low production efficiency, and coil production quality cannot be effectively guaranteed, and achieve saving Labor force, high production efficiency, and the effect of realizing mechanical automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] With reference to the drawings, the present invention will be further explained:

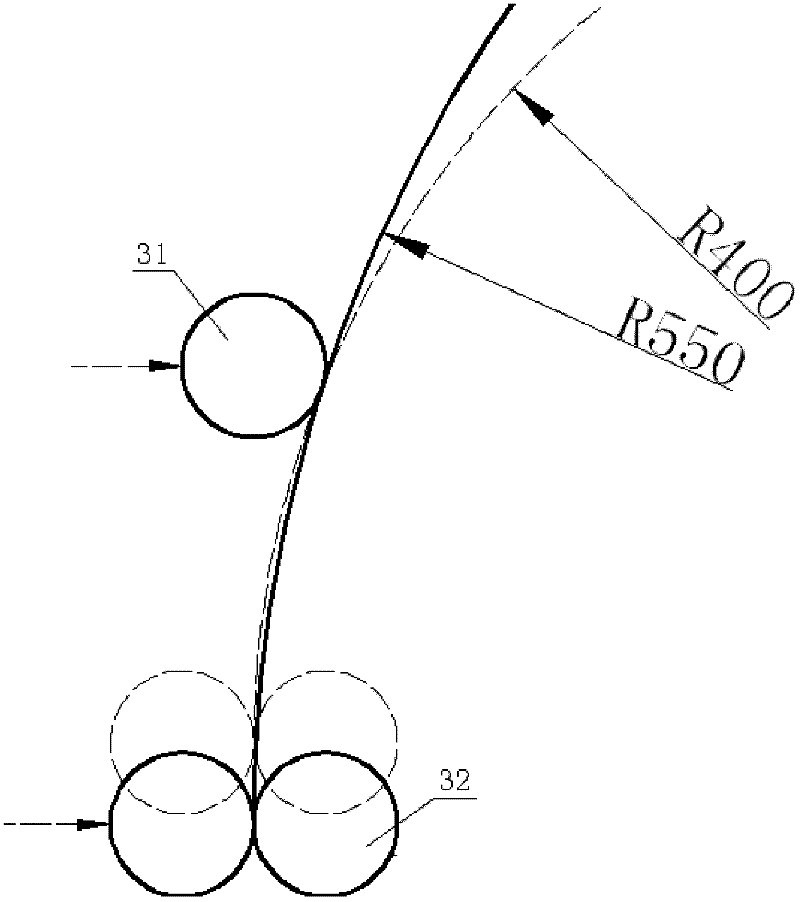

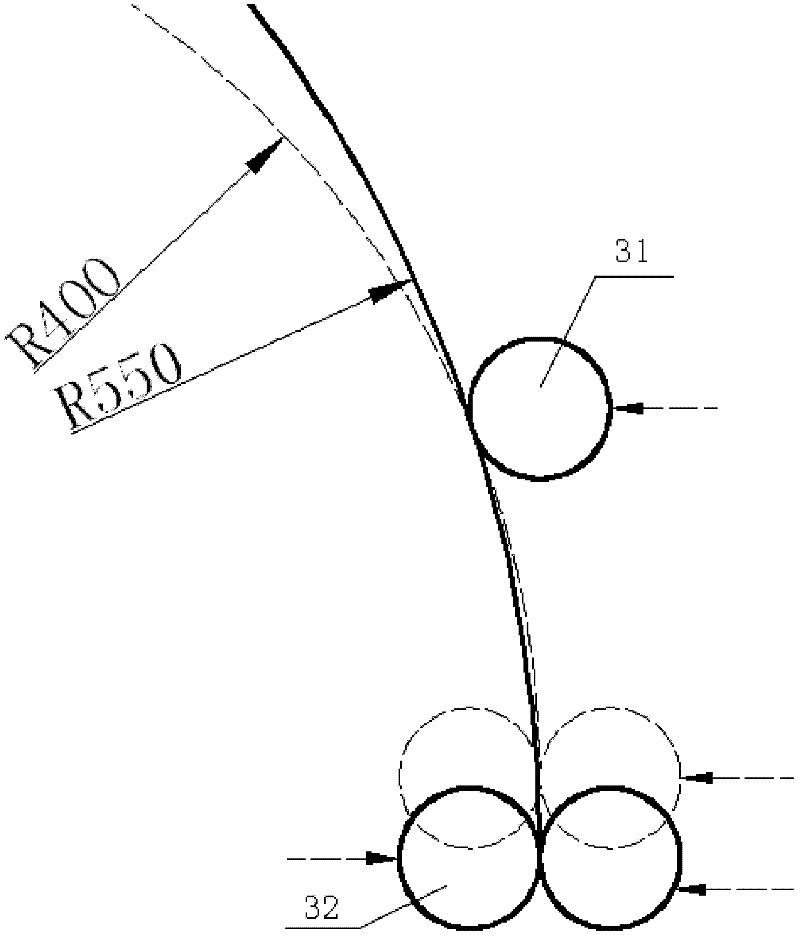

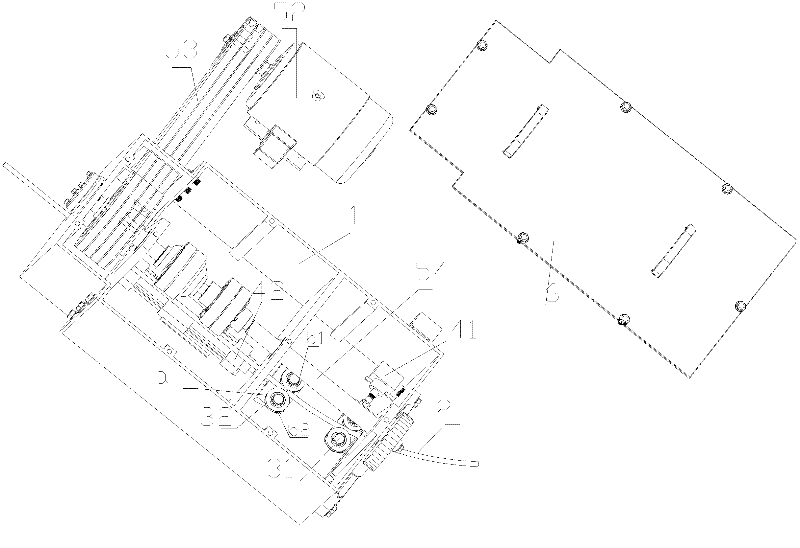

[0027] The automatic coil tube blanking machine includes a frame 1. One end of the frame 1 is a pipe feeding end 11, and the other end is a discharge end 12. The inlet 11 and the discharge end 12 are arranged in sequence There are a second guide wheel group 32 and a first guide wheel group 31 for bending the pipe 2, a second guide wheel group 32 close to the feeding end 11 and a longitudinal cylinder 42 that pushes the second guide wheel group 32 along the forward direction of the pipe The first guide wheel group 31 is connected to the transverse cylinder 41 that pushes the first guide wheel group 31 in a direction orthogonal to the forward direction of the pipe. The guide wheel group includes a bottom bracket a and is symmetrically installed on the The pair of guide wheels b1, b2 on the bottom support, the base a is provided with guide wheel mounting posts corresponding to the guide wheels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com