Yarn cleaning device of yarn feeding device for automatic winding machine

An automatic winder and yarn clearer technology, which is applied in transportation and packaging, textiles and papermaking, and conveying filamentous materials, etc. It can solve the problems of a large number of manpower/working hours, increased hairiness, and reduced production efficiency, etc., and achieves improvement. Effects of production working environment, change of wire path travel resistance, and improvement of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

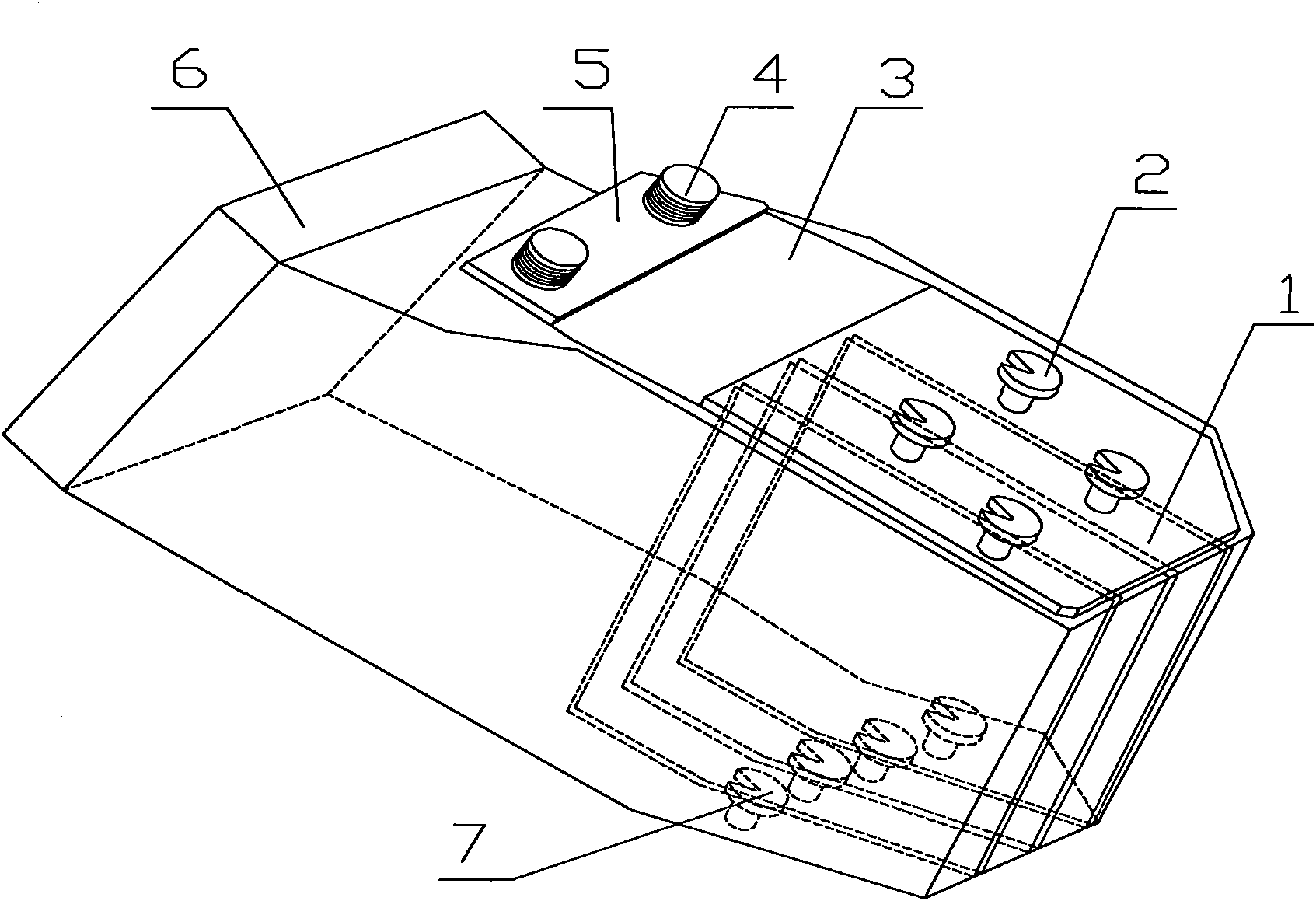

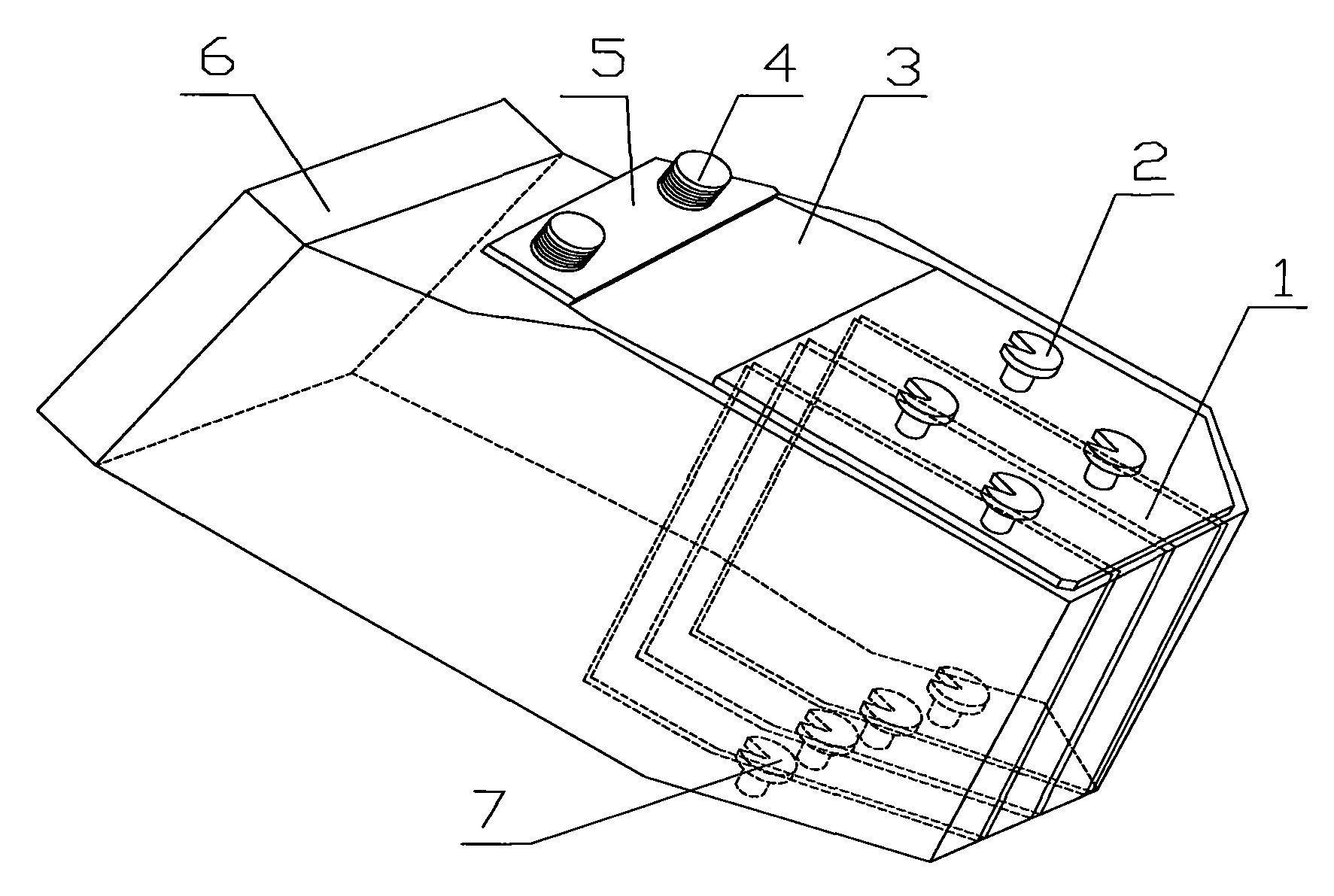

[0012] Such as figure 1 The yarn clearer of the automatic winder yarn feeding device shown includes a hollow yarn clearer body, and an air suction device 6 is provided at one end of the yarn clearer body; a yarn clearer body is also provided with a Sealing rubber cover 3, a plurality of upper yarn clearer yarn guide tile inlets 2, a plurality of lower yarn clearer yarn guide tile outlets 7 and a yarn compartment 1; the sealing rubber cover 3 is arranged on the yarn clearer body On the top, a plurality of upper yarn clearer yarn guide tile inlets 2 and a plurality of lower yarn clearer yarn guide tile outlets 7 are respectively arranged on the sealing rubber cover 3 and the bottom of the yarn clearer body, and the yarn compartment 1 are arranged in the hollow cavity of the yarn clearer body in a one-to-one correspondence from the yarn guide tile inlet 2 of the upper yarn cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com