Patents

Literature

39results about How to "Improve the production working environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

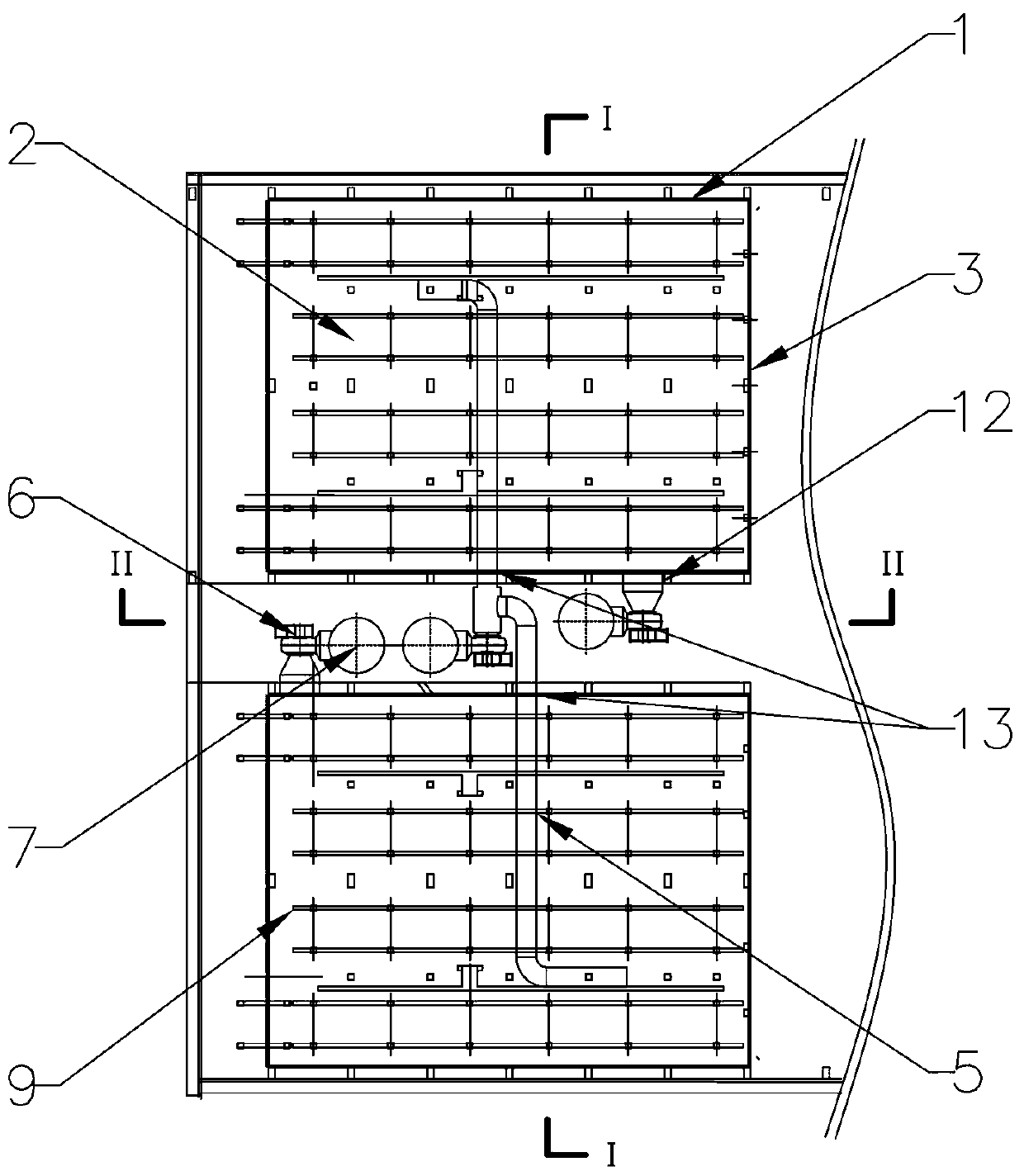

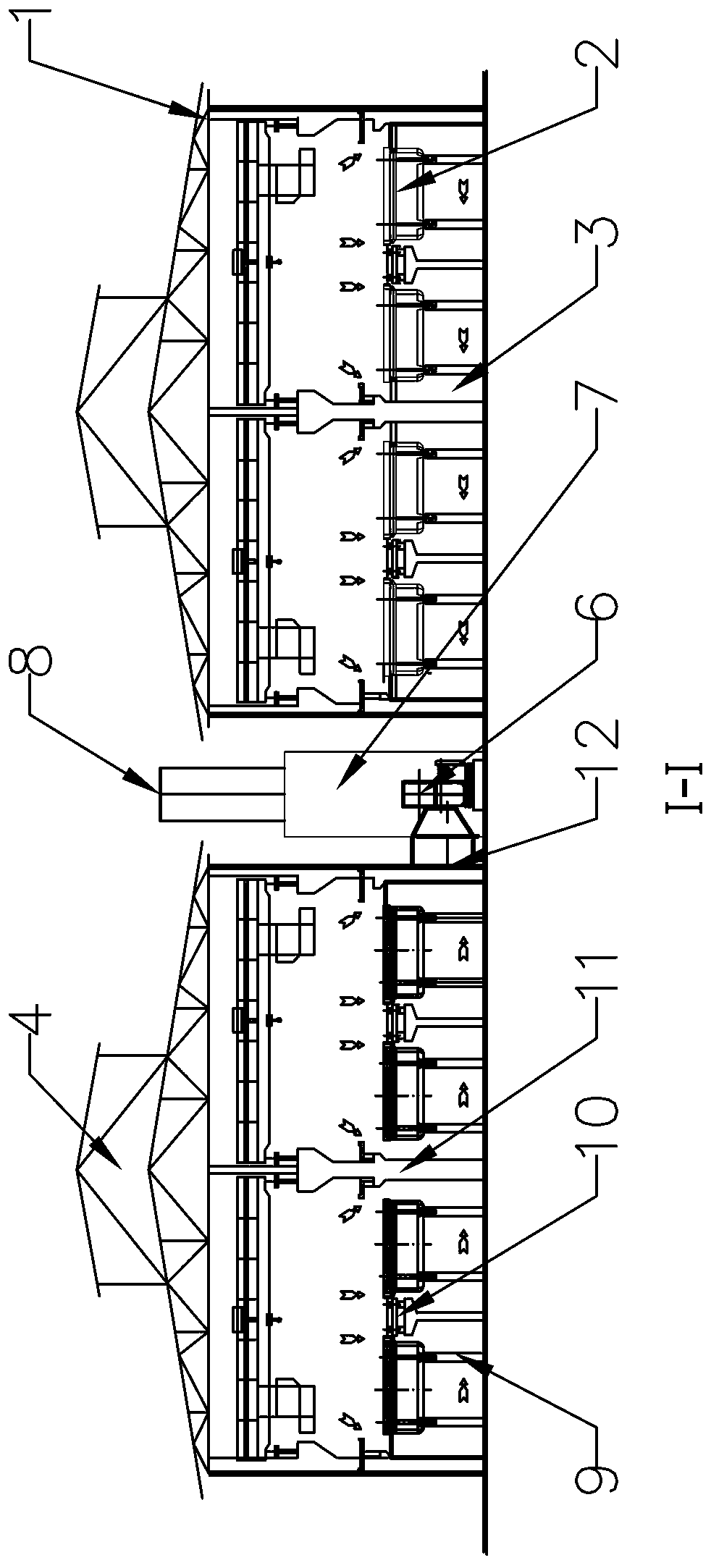

Automatic assembly production method and assembly production line of combination fireworks

InactiveCN103512435AImprove securityHigh degree of automationFireworksInformatizationTransport system

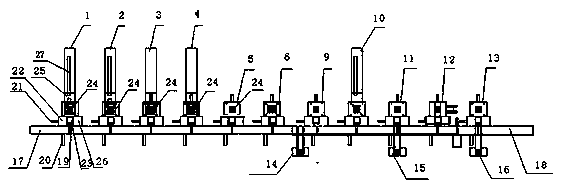

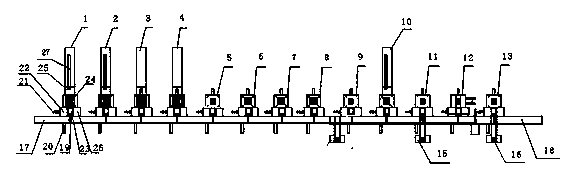

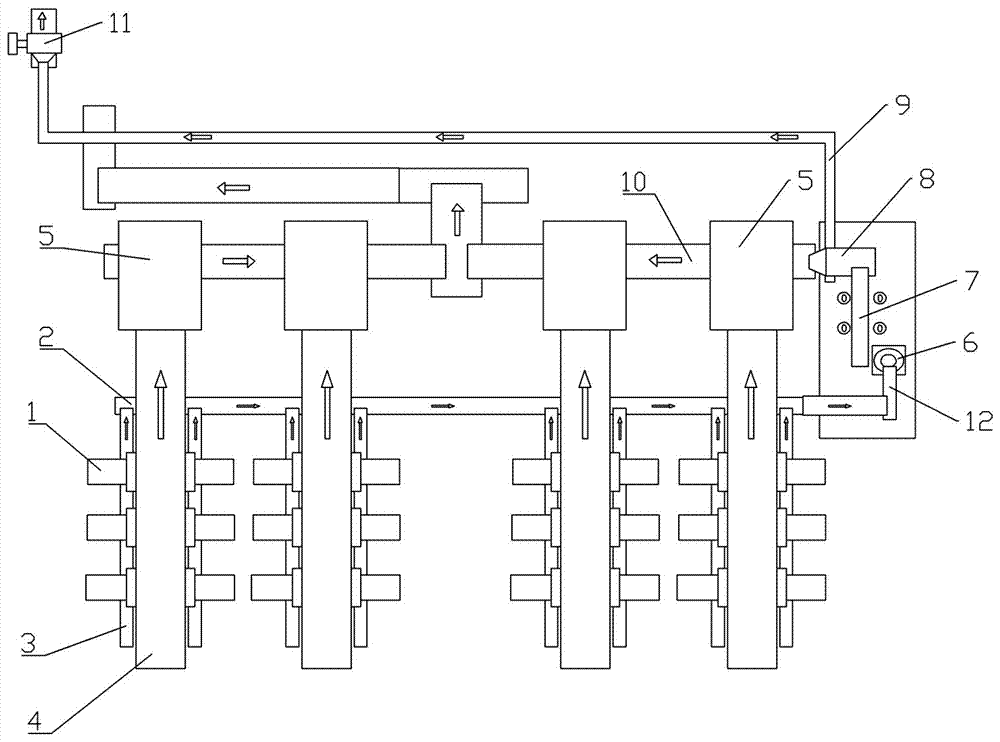

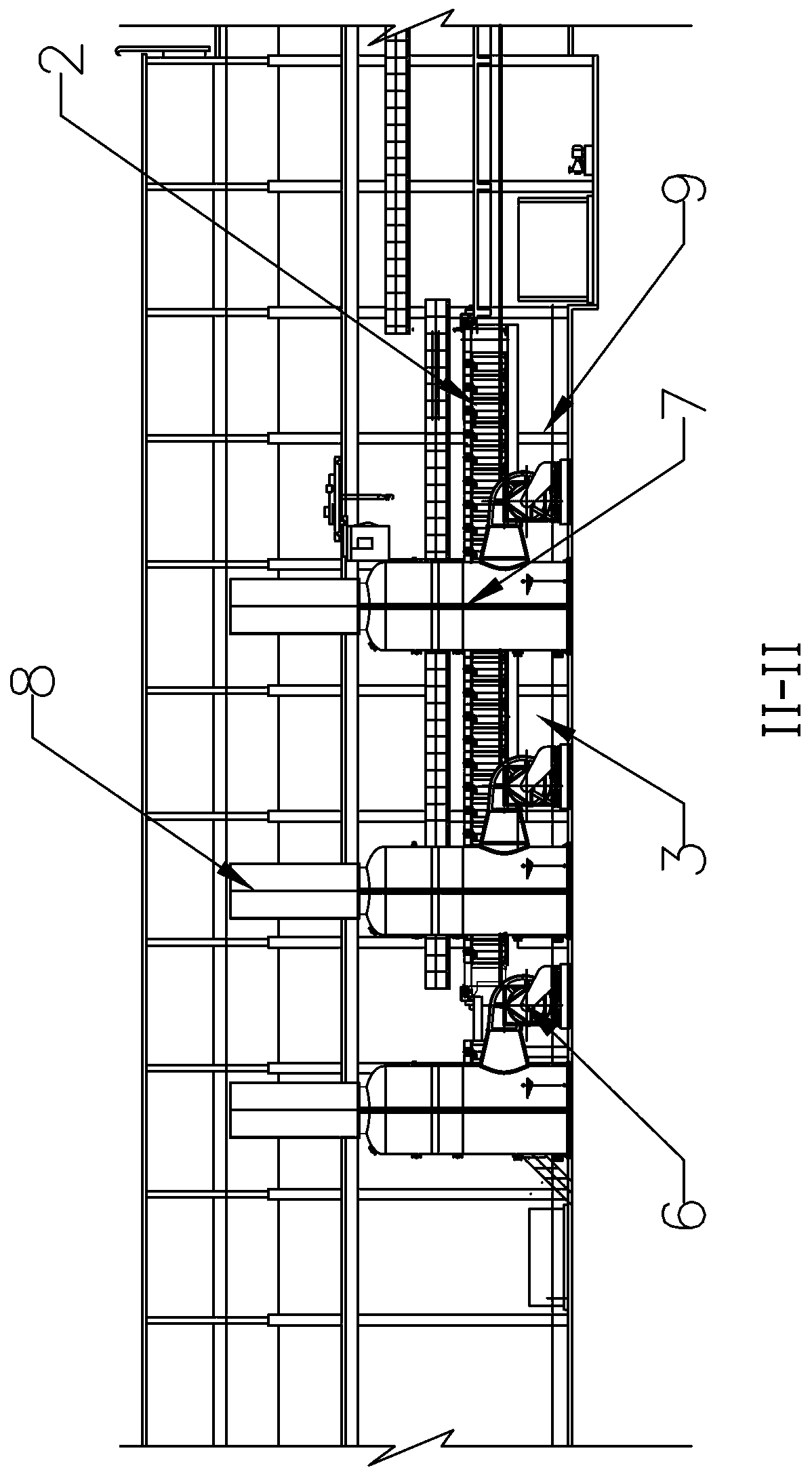

The invention relates to the technical field of firework production, and discloses an automatic assembly production method and assembly production line of combination fireworks. The assembly production line comprises a protection system, a conveying system and a firework mechanical system. The conveying system is composed of an upper conveyor belt and a lower conveyor belt, the upper conveyor belt conveys inner barrel templates filled with inner barrel tube banks, and the lower conveyor belt conveys outer barrel templates filled with outer barrel tube banks. The upper conveyor belt is arranged on the inlets of inner barrel tube bank assembly equipment which is arranged in a plurality of anti-explosion rooms of the protection system respectively. The lower conveyor belt is arranged on the outlets of the outer barrel tube bank assembly equipment which is arranged in the anti-explosion rooms of the protection system respectively. The lower conveyor belt is parallel to the upper conveyor belt. A traditional firework production process technology is improved, researched and developed, factorization, mechanization, informatization, standardization and scalization can be achieved, the automatic assembly production line has the advantages of being high in safety, small in occupied space, high in automation degree and efficiency, small in labor consumption, good in production working environment and the like, and the development mode of a firework and cracker industry can be fundamentally transformed.

Owner:HENAN LINXIAO SCI & TECH DEV

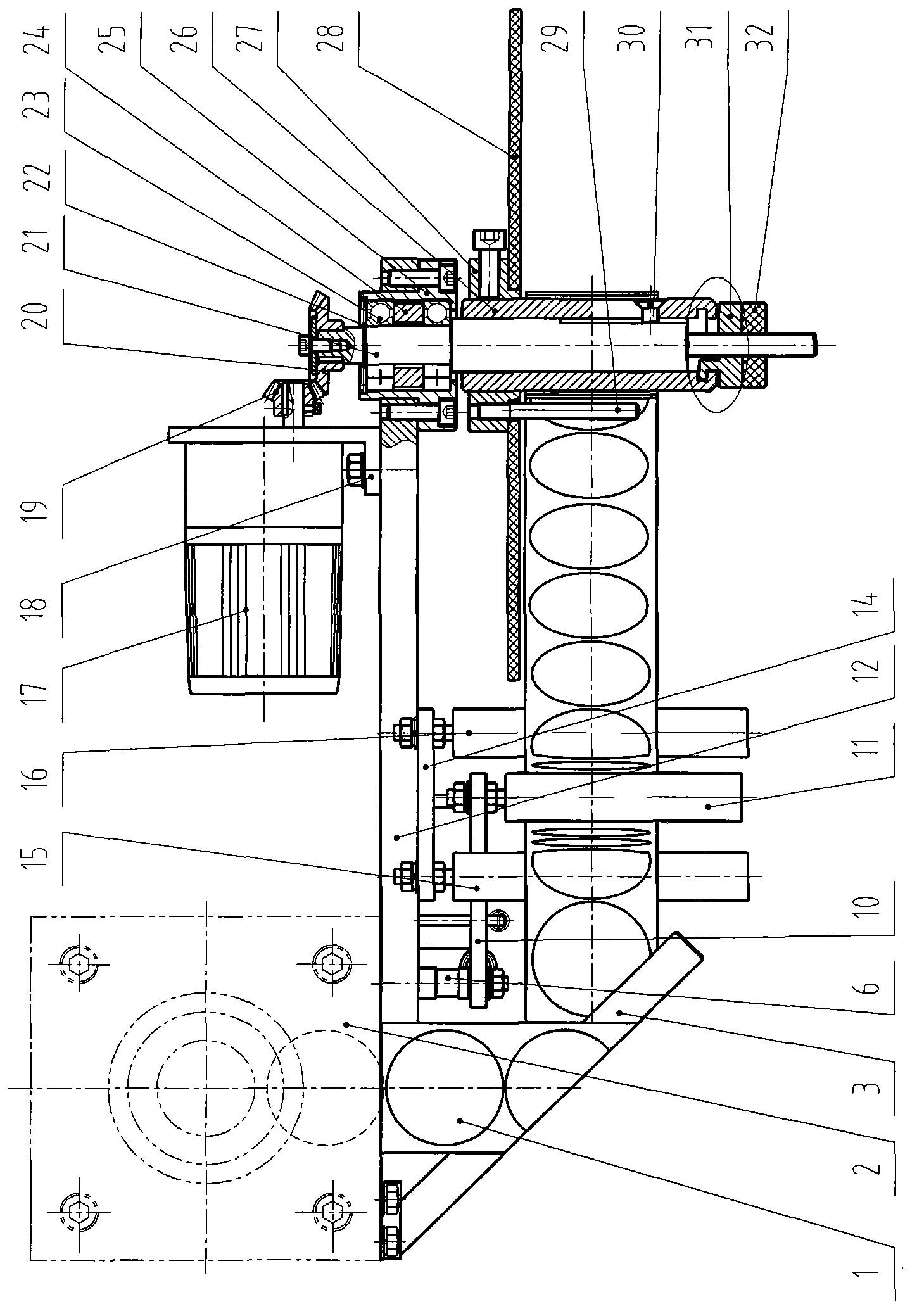

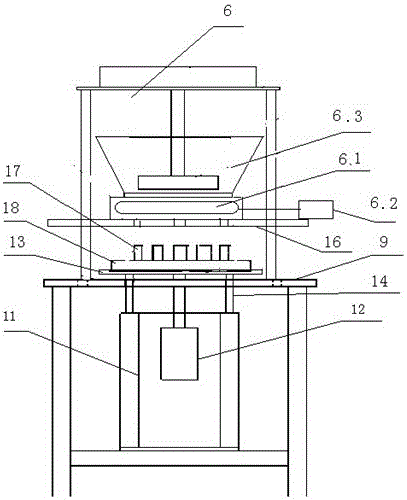

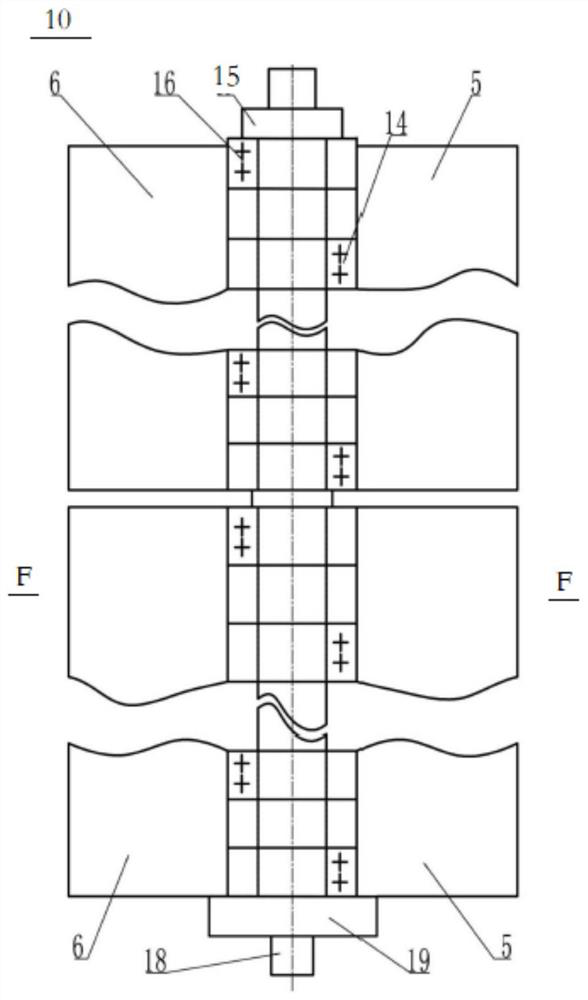

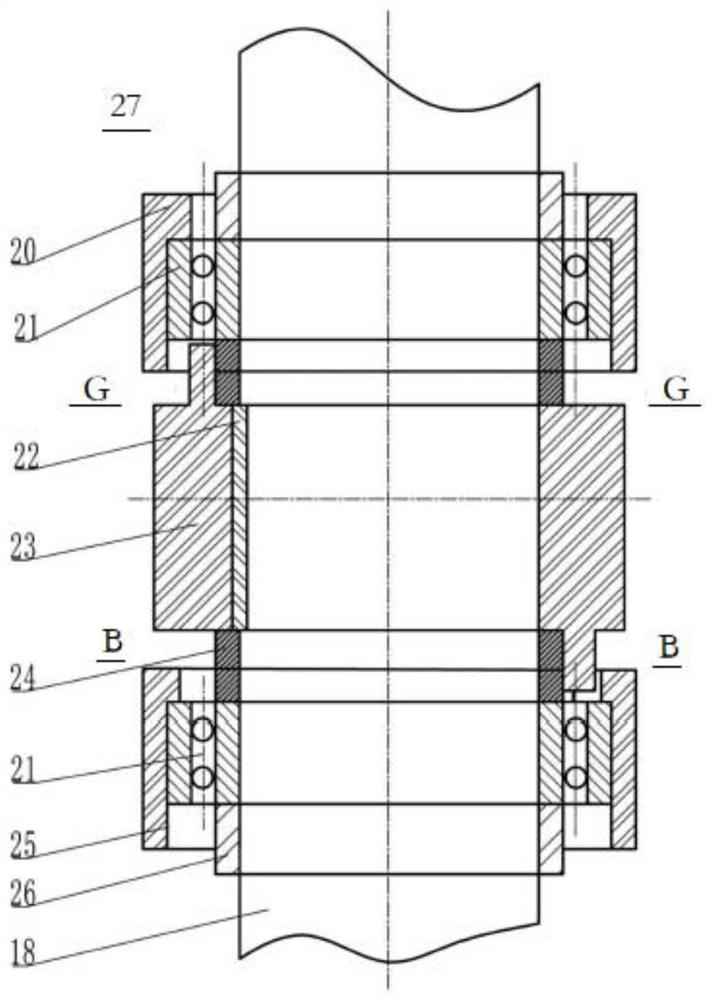

Automatic assembly method and assembly machine of inner barrels and outer barrels for producing combination fireworks

InactiveCN103512432AImprove securityHigh degree of automationFireworksInformatizationWorking environment

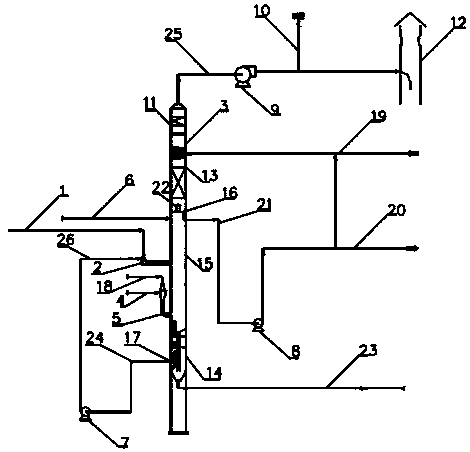

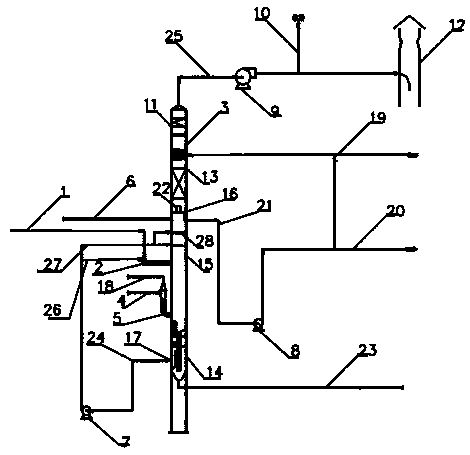

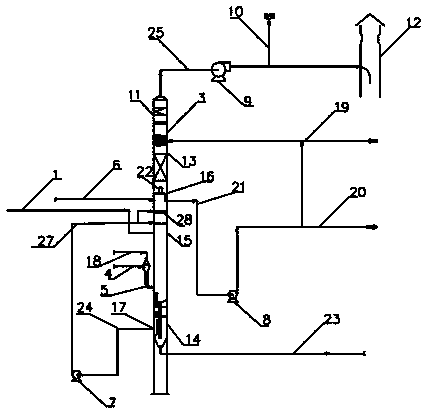

The invention relates to the technical field of firework production equipment, and discloses an automatic assembly method and assembly machine of inner barrels and outer barrels for producing combination fireworks. The automatic assembly machine of the inner barrels and the outer barrels comprises an inner barrel template separating mechanism and an automatic assembly mechanism. The inner barrel template separating mechanism enables inner barrel templates filled with propellant powder to enter an upper working plane for process separation. The automatic assembly mechanism enables outer barrel templates filled with propellant powder to enter a lower working plane for online assembly with the inner barrels, wherein in the outer barrel templates, base pads are pressed. The side, located on the rack, of the upper working plane is provided with an inner barrel template inlet and outlet working mechanism which enables the inner barrel templates to enter the starting separating station of the inner barrel templates. The starting separating station of the inner barrel templates is provided with the inner barrel template separating mechanism which allows the inner barrel templates to be separated from inner barrel tube banks. A traditional firework manufacturing process technology is improved, researched and developed, the automatic assembly machine has the advantages of being high in safety, small in occupied space, high in automation degree and efficiency, small in labor consumption, good in production working environment and the like, factorization, mechanization, informatization, standardization and scalization can be achieved, and the development mode of a firework and cracker industry can be fundamentally transformed.

Owner:HENAN LINXIAO SCI & TECH DEV

Yarn cleaning device of yarn feeding device for automatic winding machine

InactiveCN102337617AReduce adhesionChange travel resistanceFilament handlingTextiles and paperYarnWinding machine

The invention relates to a yarn cleaning device, in particular to a yarn cleaning device of a yarn feeding device for an automatic winding machine, which comprises a hollow yarn cleaning device body. One end of the yarn cleaning device body is provided with an air drafting suction device, a sealing rubber cover, a plurality of upper yarn guiding ceramic plate inlets, a plurality of lower yarn guiding ceramic plate outlets and a yarn compartment; and the sealing rubber cover is arranged at the top of the yarn cleaning device body, and the upper yarn guiding ceramic plate inlets and the lower yarn guiding ceramic plate outlets are respectively arranged on the sealing rubber cover and the bottom of the yarn cleaning device body. When the yarn cleaning device of the yarn feeding device is installed on the automatic winding machine, blurs and dust of yarns and the working space can be eliminated. Moreover, yarn feeding management suitable for the modulus and the number of yarns of different automatic winding machines can be customized according to actual needs of customers. Meanwhile, the running resistance in yarn channels can be changed via improvement of a yarn guiding magnetic sheet of the yarn cleaning device, and the product quality can be improved.

Owner:上海施迈尔精密陶瓷有限公司

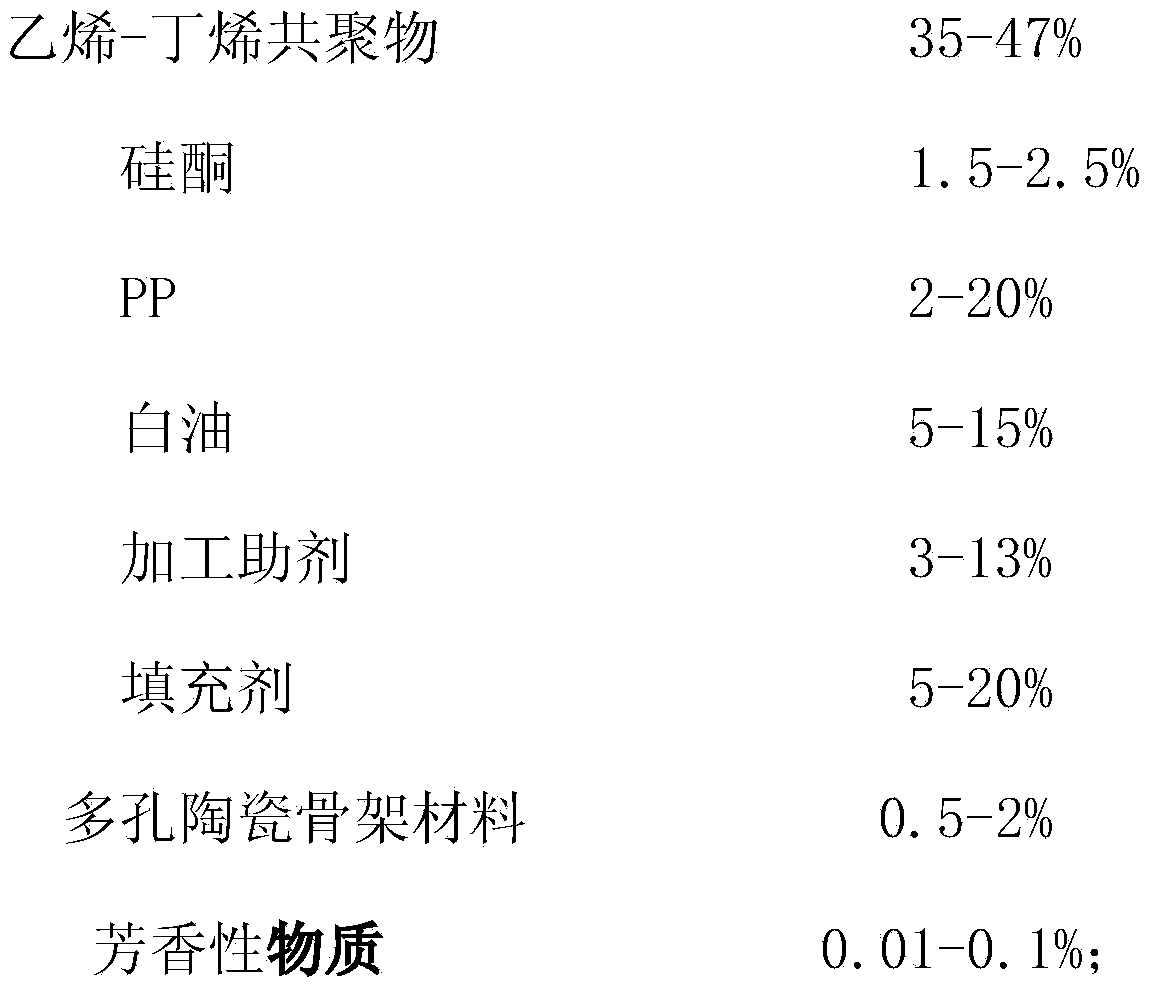

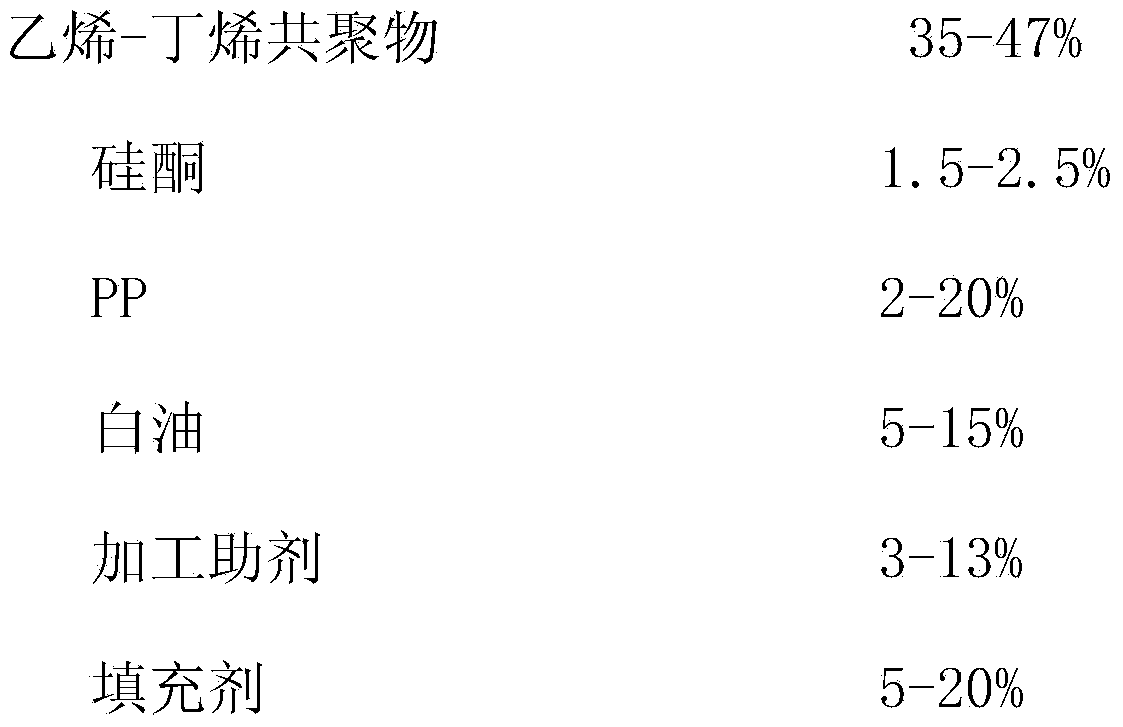

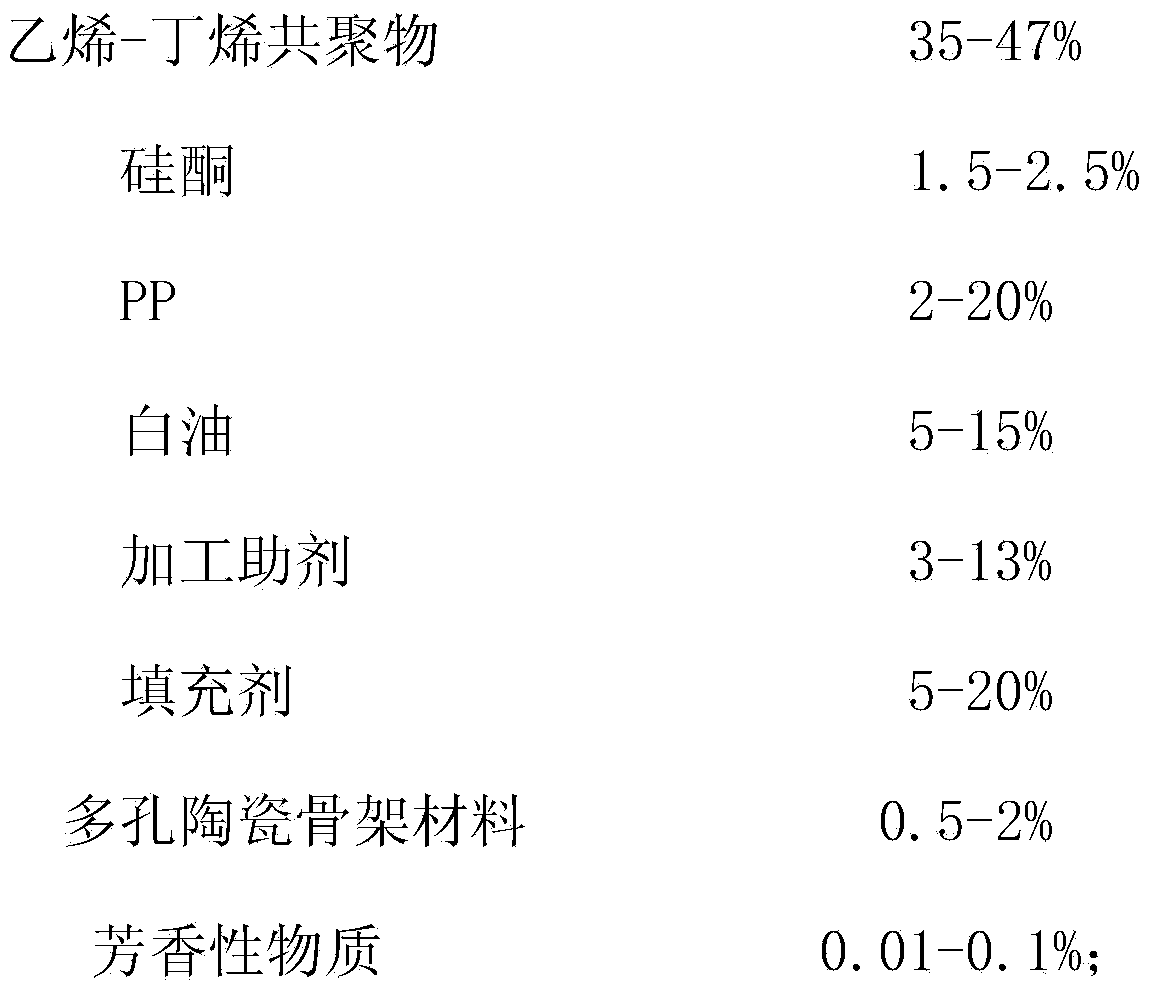

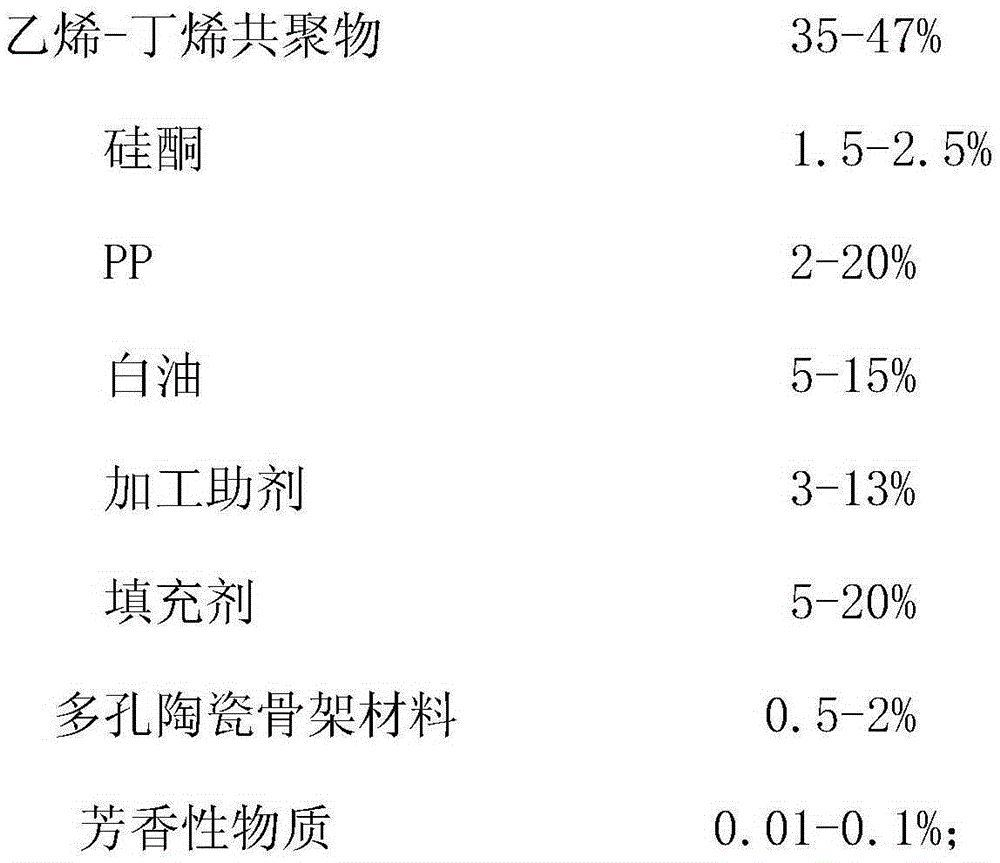

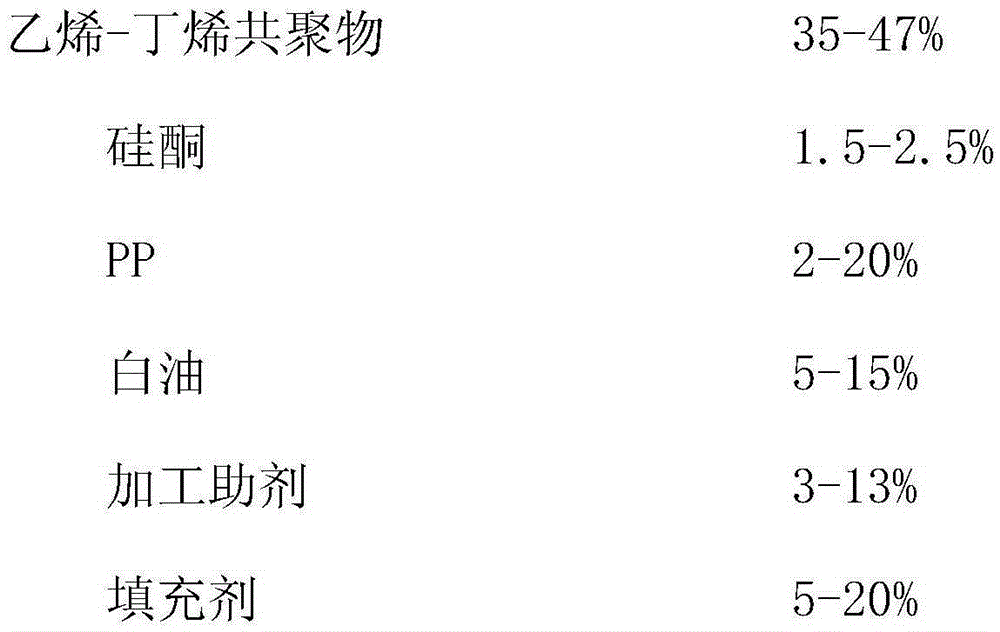

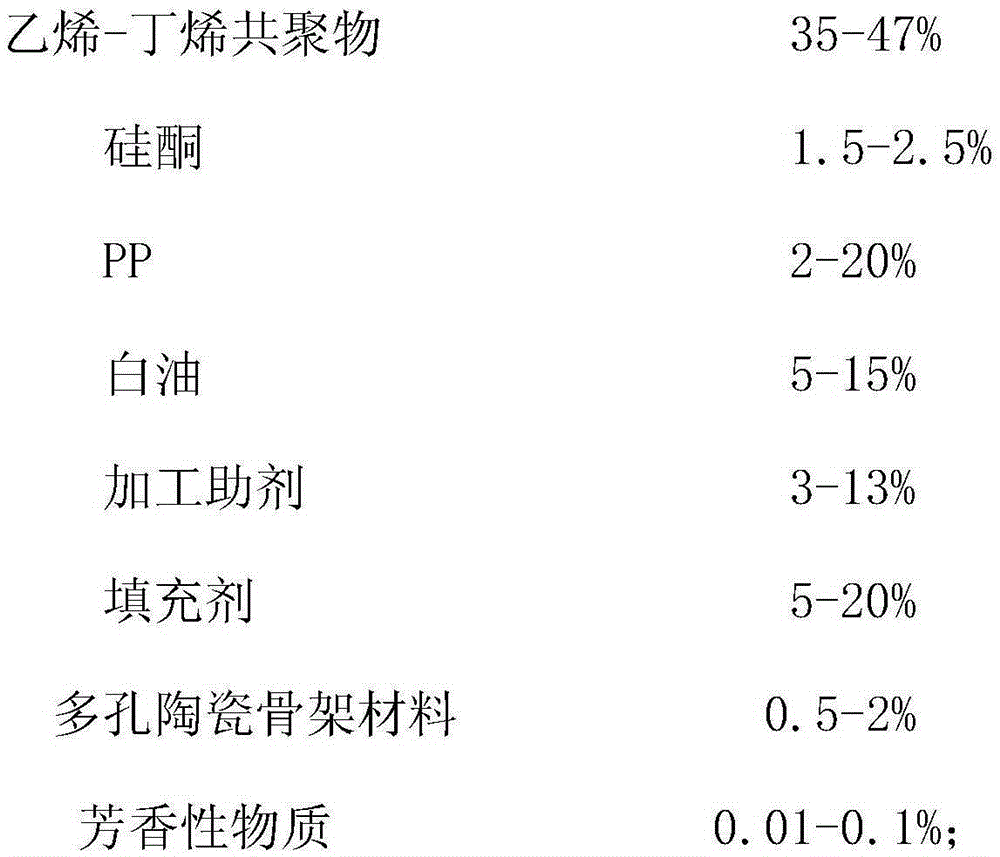

Aromatic plastic material for plastic wire and preparation method thereof

ActiveCN104004261ASolve the bad plastic smellImprove the production working environmentWire rodProcedure Agents

The invention discloses an aromatic plastic material for a plastic wire. The aromatic plastic material is prepared from the following components in percentage by mass: 35%-47% of ethylene-butylene copolymer, 1.5%-2.5% of silicone, 2%-20% of PP, 5%-15% of white oil, 3%-13% of processing aid, 5%-20% of filling agent, 0.5%-2% of porous ceramic framework material and 0.01%-0.1% of aromatic substance, wherein the porous ceramic framework material adsorbs and contains the aromatic substance. The invention further discloses a preparation method for the aromatic plastic material for the plastic wire. The preparation method comprises the steps of preparing materials, charging oil, stirring, extruding, cooling, pelletizing, and the like. The product disclosed by the invention can be used for storing the aromatic substance, so that an earphone product can release fragrance under usage and friction conditions, and can provide different fragrances according to needs of a consumer, and therefore, the problems that all plastic materials after being processed and formed are severe in plastic smell, strong in oil smell, and the like, are solved; the aromatic plastic material can be widely applied to manufacturing consumption type electronic product signal cable products such as earphone cable, and the like.

Owner:DONGGUAN YINGTONG WIRE +1

Method for preventing smoke of converter from polluting environment

ActiveCN106702076AReduce pollutionKeep healthyManufacturing convertersSmelting processWorking environment

The invention provides a method for preventing smoke of a converter from polluting the environment. The method comprises the following steps: arranging at least four spray nozzles on the periphery of a fire hole and dividing the spray nozzles into two groups, wherein one group of the spray nozzles are positioned at the 1 / 4 radius in the front of the converter while the other group of the spray nozzles are positioned at the rest 3 / 4 radius; arranging a blowing process abnormal smoke purifying button for controlling all the spray nozzles on a master control chamber; arranging an iron charging furnace gas purifying button which controls the 1 / 4 spray nozzles in the front of the converter on an iron charging room in the front of the converter; arranging a steel tapping smoke purifying button which controls the rest 3 / 4 spray nozzles on a steel tapping operation table; starting the iron charging furnace gas purifying button during iron charging; starting the blowing process abnormal smoke purifying button when splashing is about to be caused or has been caused in a smelting process; and starting the steel tapping smoke purifying button or the blowing process abnormal smoke purifying button during tapping of duplex front half steel of the converter. By the method, converter smoke can be effectively suppressed and purified, pollution of harmful smoke to the air and the environment of the inside and the outside of a factory is reduced greatly, the production and working environment and the air quality are improved, and health of staff and nearby residents is guaranteed.

Owner:ANGANG STEEL CO LTD

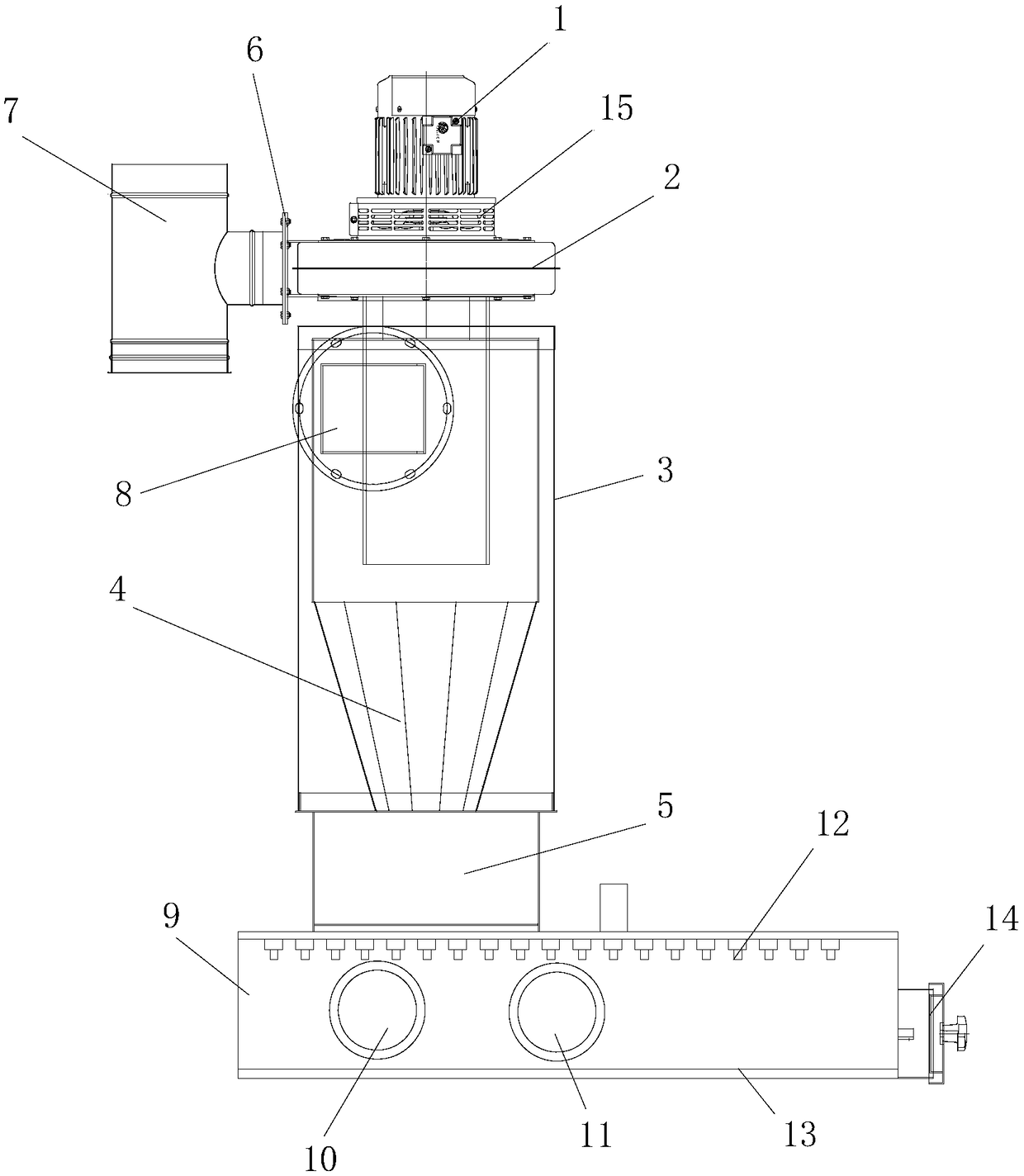

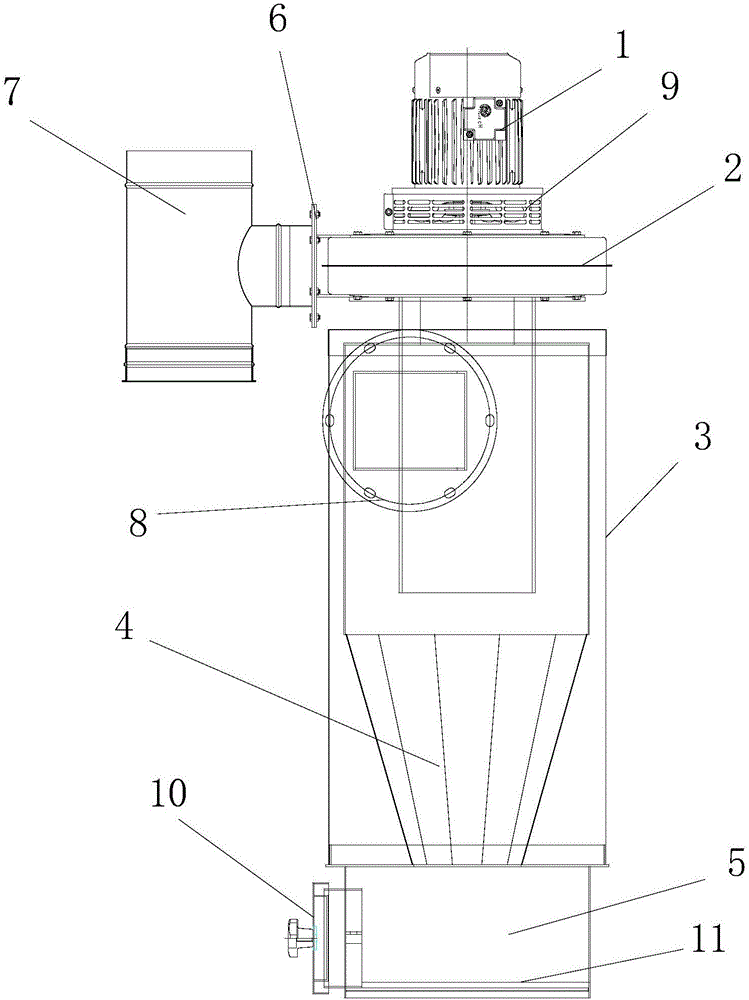

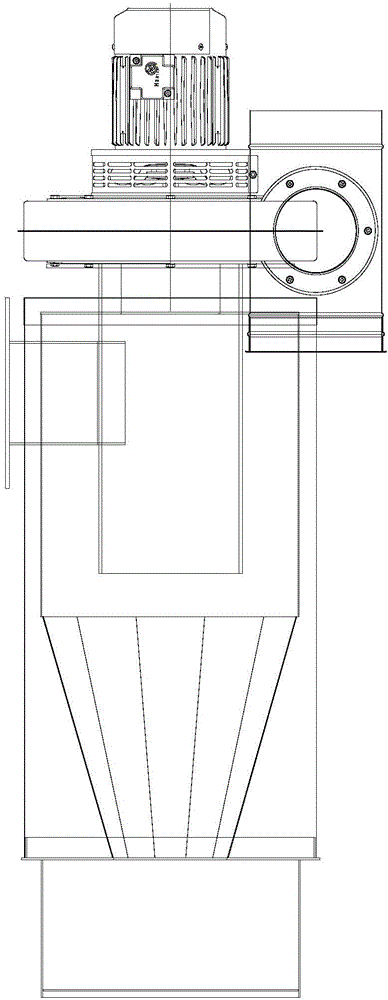

Boiler Dust Collector

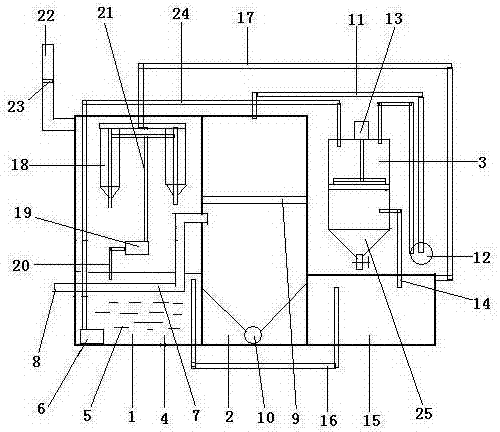

ActiveCN106402913BImprove the production working environmentReasonable structural designLighting and heating apparatusDust explosionSpray nozzle

The invention relates to the field of boiler dust removing devices, in particular to a boiler dust remover. The boiler dust remover comprises a motor, a motor bellows, a dust box, a conical cloth bag and a collection box. The motor bellows is installed on the upper portion of the dust box and communicates with the conical cloth bag arranged inside the dust box. One side of the motor bellows communicates with an exhaust duct through a flange plate. One side of the dust box is provided with an air inlet pipeline. The collection box communicates with the lower portion of the dust box. The lower portion of the collection box is connected with a drying oven which is of a double-layer structure. A heat inlet and a heat outlet are formed in the side wall of the drying oven. Spraying nozzles are formed in the inside top wall of the drying oven. A collection plate is in sliding fit with the bottom of the drying oven and is connected with an oven door. The boiler dust remover is reasonable in structural design, good in dust removing effect, and capable of removing dust in delivery media, especially winnowing dust, dust in raw materials of a pulverizer and dust in a machining process, dust explosion is avoided, and the service cycle of equipment is prolonged.

Owner:TIANJIN KAI PUSEN HEATING EQUIP

Boiler slag and dust removing equipment

InactiveCN106439872AHigh thermal efficiencyReasonable structural designLighting and heating apparatusBoiler slagEngineering

Boiler slag and dust removing equipment comprises a boiler, a conveying plate and a slag storage chamber, wherein one end of the conveying plate is arranged on the lower part of a slag outlet of the boiler; a balance weight is arranged at the bottom of the other end of the conveying plate; a rotating shaft is arranged in the middle of the conveying plate; a high-pressure blast device is arranged under the balance weight; a dust removing tube is arranged on the upper part of the conveying plate; a one-way valve is arranged on the dust removing tube; the bottom end of the dust removing tube is connected with a dust hood; a conveying belt is arranged below the dust hood; the other end of the conveying belt is positioned above the storage chamber; and an impulse type cloth-bag dust collecting device is arranged at the upper end of the storage chamber. The boiler slag and dust removing equipment is reasonable in structural design; and slag is removed conveniently and quickly, raised dust is avoided effectively, running effect is good, manufacturing cost is low, and therefore, the boiler slag and dust removing equipment is easy to popularize and use on a large scale.

Owner:无锡市鑫德热电设备有限公司

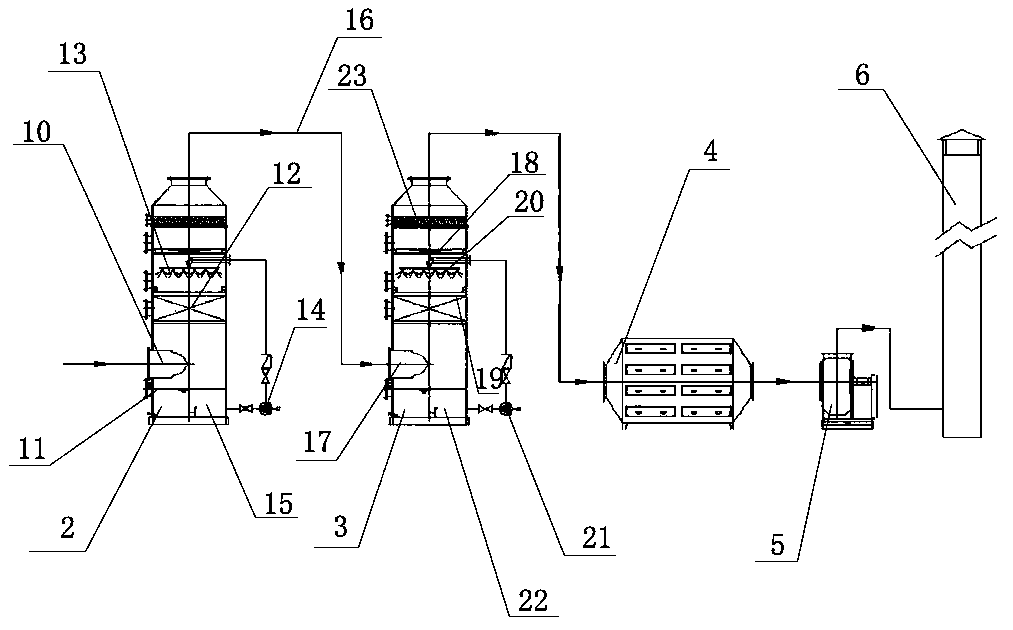

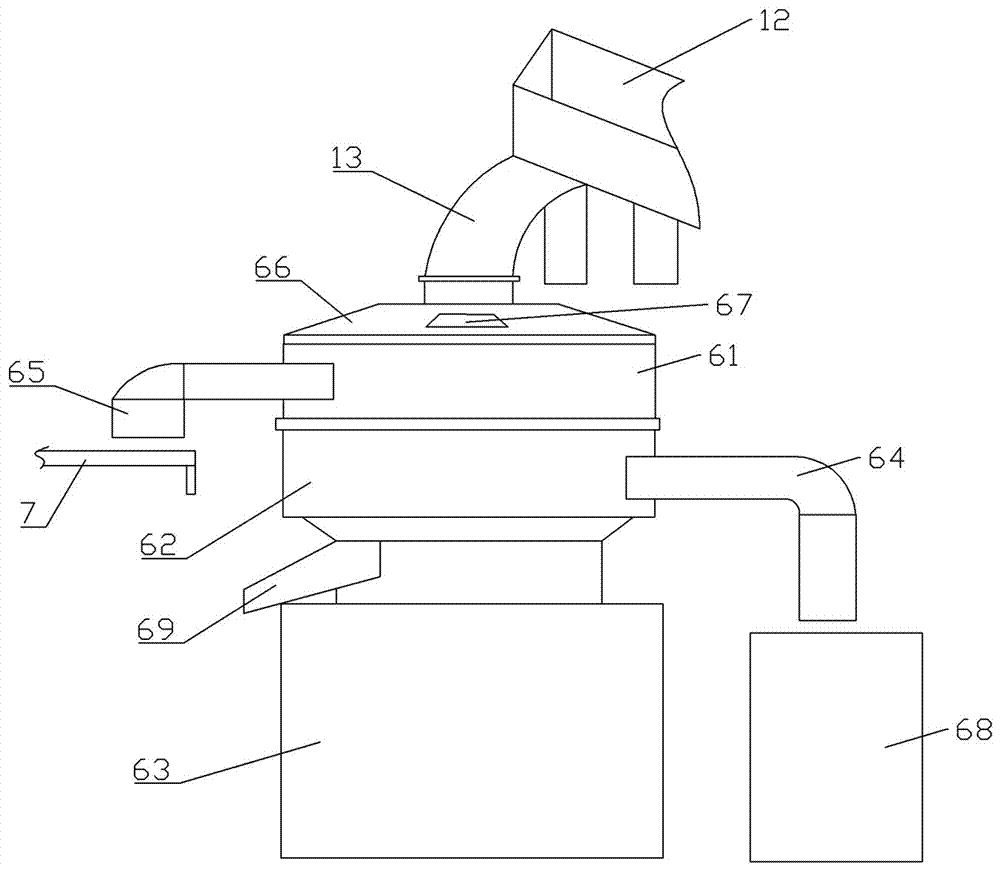

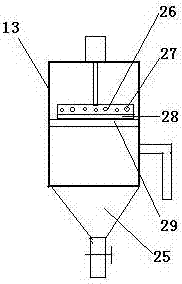

Waste gas treatment system of coated sand workshop

PendingCN108905458AGood for healthReasonable structureUsing liquid separation agentWorking environmentWaste treatment

The invention relates to a waste gas treatment system of a coated sand workshop. The waste gas treatment system comprises a plurality of top suction type waste gas collection hoods installed in a production workshop, wherein the top suction type waste gas collection hoods are connected to a swirling flow plate tower for dust removing through a pipeline system, the rear of the swirling flow plate tower is sequentially connected to a filler tower for oxidization dissolving neutralization and an active carbon box for adsorption treatment, and is connected to a discharge chimney through a fan connected on the rear of the active carbon box, the top suction type waste gas collection hood is tapered gas collection hood, the upper portions of the top suction type waste gas collection hoods are connected to middle pipes in parallel respectively through a branch pipes or are externally connected to the gas inlet on the side wall of the lower portion of the swirling flow plate tower through a total pipe, and the branch pipes and the middle pipes or the total pipe form the pipeline system. According to the present invention, the waste gas treatment system has characteristics of reasonable structure, convenient installation and use, production working environment improving, worker health achieving, production hazard reducing, work efficiency improving and the like.

Owner:HUZHOU NANFENG MACHINERY MFG

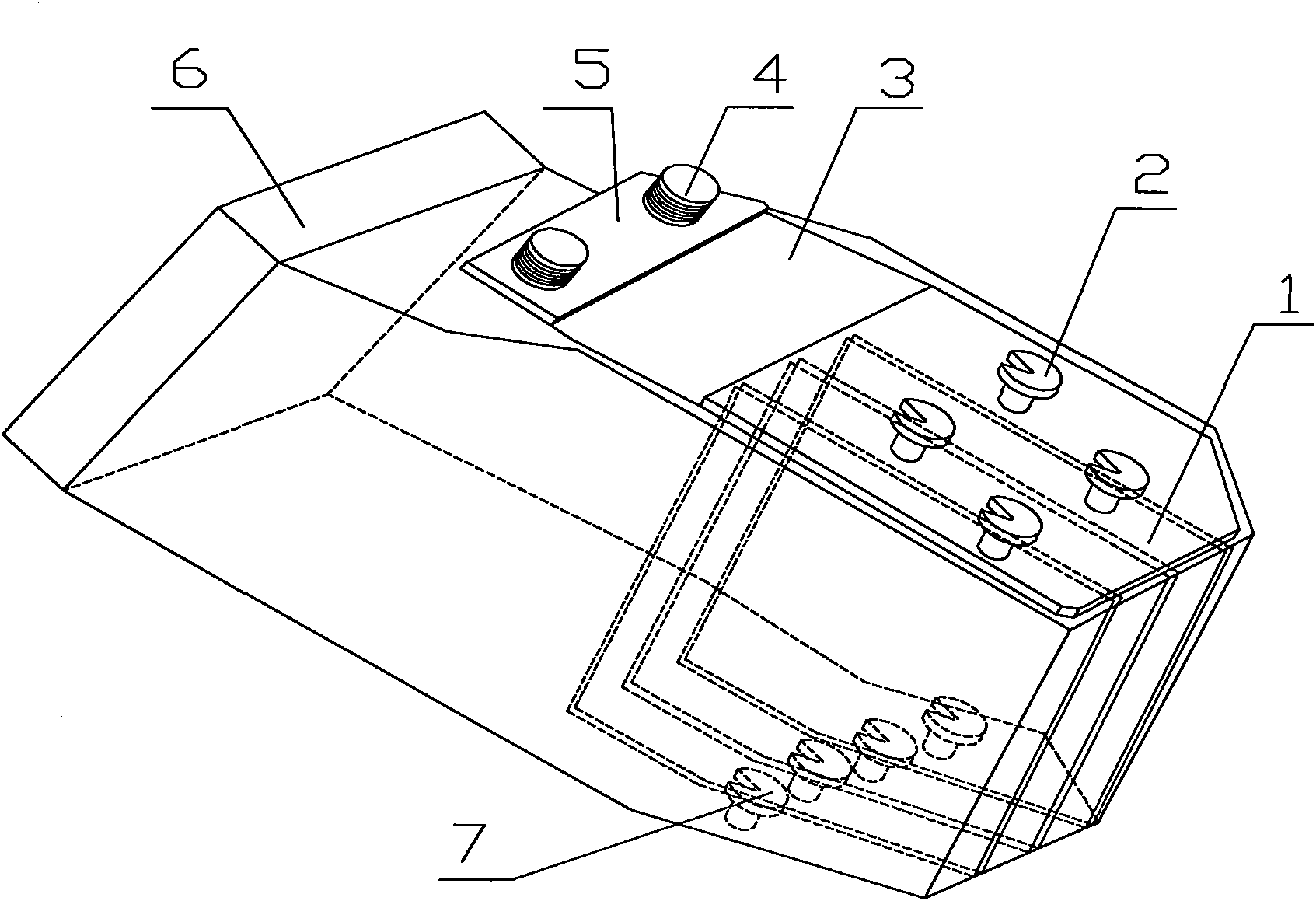

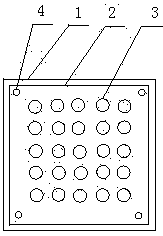

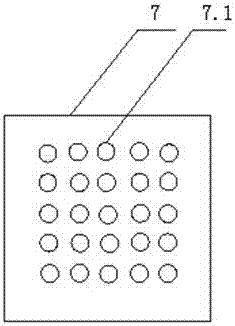

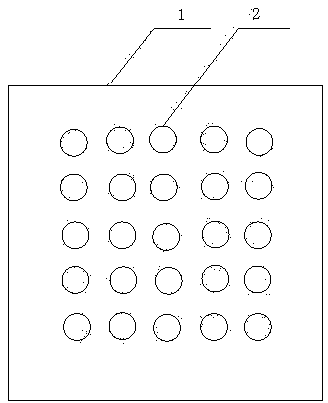

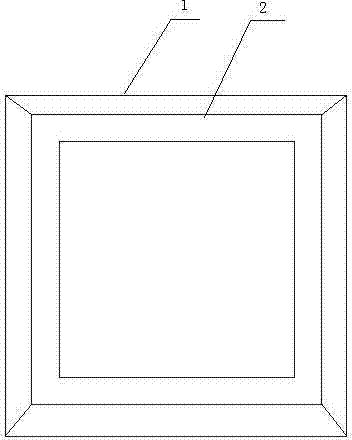

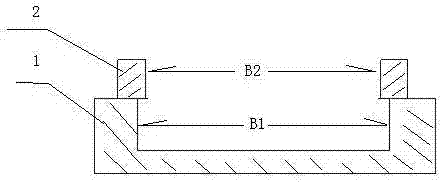

Inner barrel template used for automatic assembling production of combined fireworks

The invention relates to the technical field of firework production equipment dies and discloses an inner barrel template used for automatic assembling production of combined fireworks. The inner barrel template is composed of square or rectangular inner barrel hole plates 1 and supporting plates 2, wherein the square or rectangular inner barrel hole plates 1 and the supporting plates 2 are used for installing a plurality of inner barrel pipe bodies of combined fireworks. Inner barrel pipe holes 3 which are evenly distributed in a square or rectangular mode are formed in the centers of the square or rectangular plates. The four corners of the inner barrel hole plates 1 are provided with positioning pin holes 4 corresponding to positioning pins 5 arranged on the four corners of the supporting plates. The length of the bordism of each supporting plate 2 is 10mm smaller than that of each inner barrel hole plate. The inner barrel template is a mechanically-produced die, can improve labor efficiency, is developed by improving and researching traditional firework production technologies, can achieve the purposes that factorization, mechanization, informatization, standardization and large scale combined firework production has the advantages of being safe and efficient, the number of participators is small, and the production environment is good, and can achieve the right-about-face of the development mode of the firework and cracker industry.

Owner:HENAN LINXIAO SCI & TECH DEV

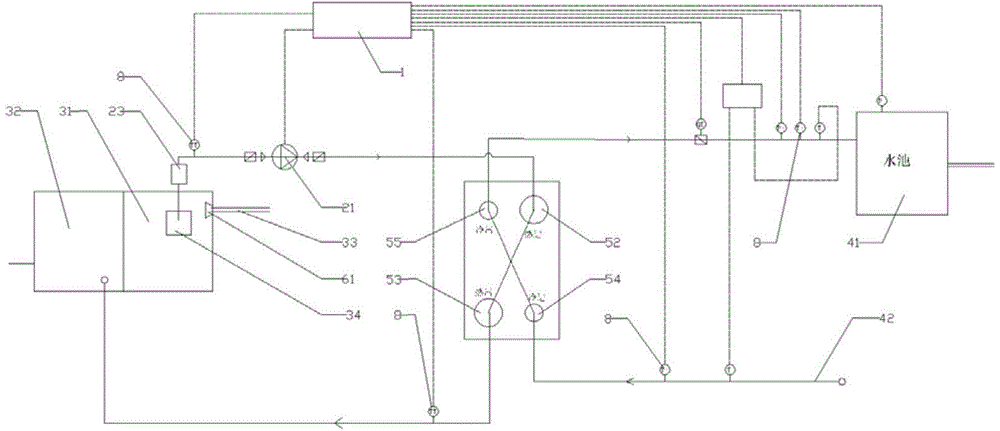

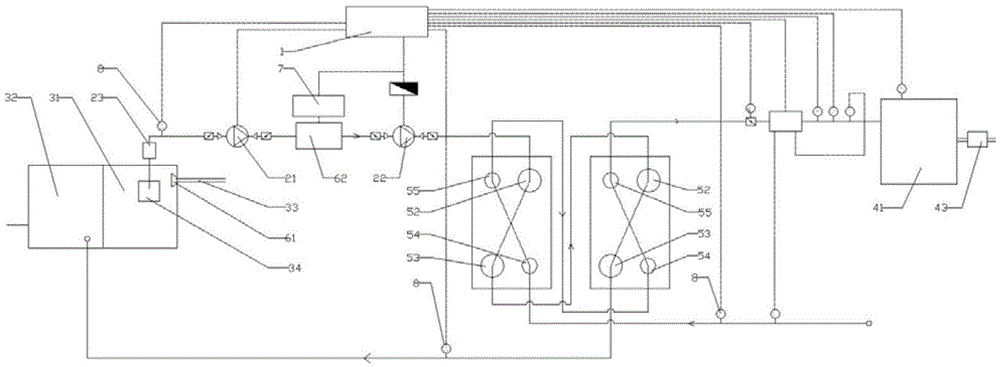

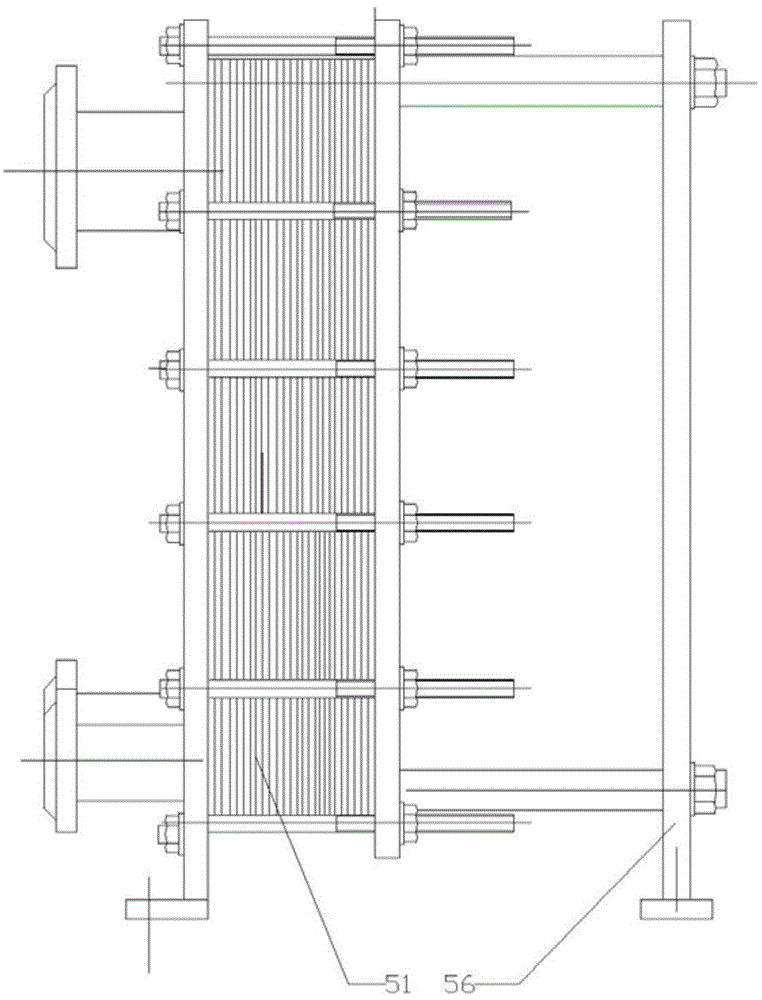

Printing and dyeing wastewater afterheat recovery device

InactiveCN104061701AGuarantee production safetyReduce investmentOther heat production devicesWater heatersSewageDyeing wastewater

The invention discloses a printing and dyeing wastewater afterheat recovery device, and aims to provide a printing and dyeing wastewater afterheat recovery device capable of recovering heat energy, saving energy, reducing emissions and effectively improving a production environment. The device comprises a wastewater tank, a water pump I and a field control cabinet, wherein the wastewater tank comprises a front heat recovery tank and a rear heat recovery tank; the front heat recovery tank is provided with a wastewater inlet. The device also comprises a clean water tank, a clean water supply pipe and one or more mutually connected afterheat recovery devices, wherein each afterheat recovery device comprises a wastewater heat exchange flow passage and a clean water heat exchange flow passage; a plurality of heat exchange plates are arranged outside each of the wastewater heat exchange flow passages and the clean water heat exchange flow passages; the front heat recovery tank, the water pump I, the wastewater heat exchange flow passages and the rear heat recovery tank are sequentially communicated through a pipeline; the clean water supply pipe, the clean water heat exchange flow passages and the clean water tank are sequentially communicated through a pipeline. The device can be widely applied to the field of printing and dyeing wastewater afterheat recovery.

Owner:刘猛 +1

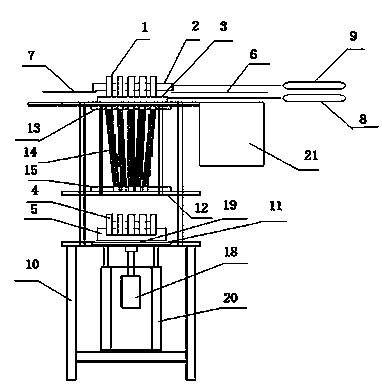

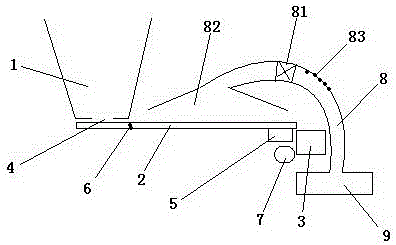

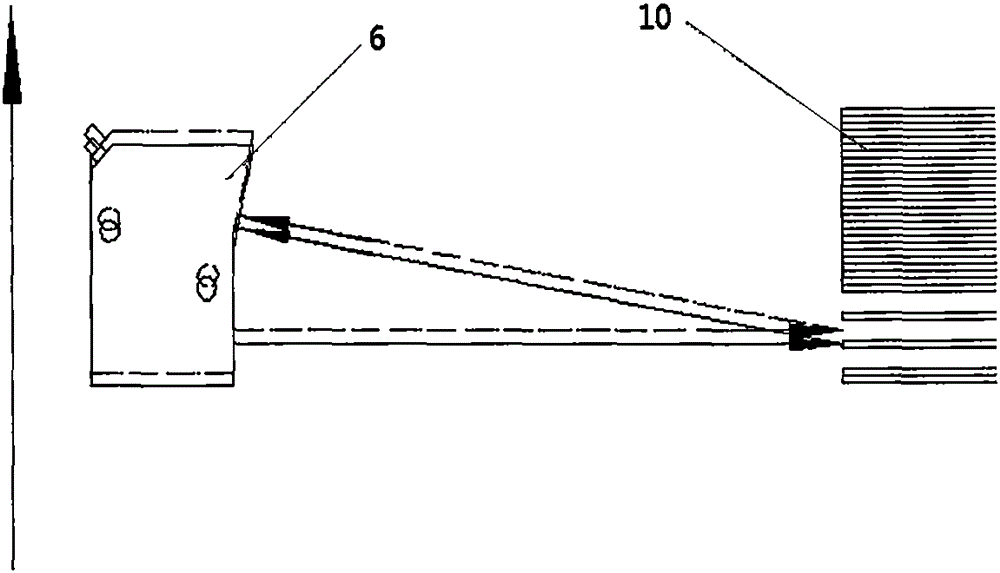

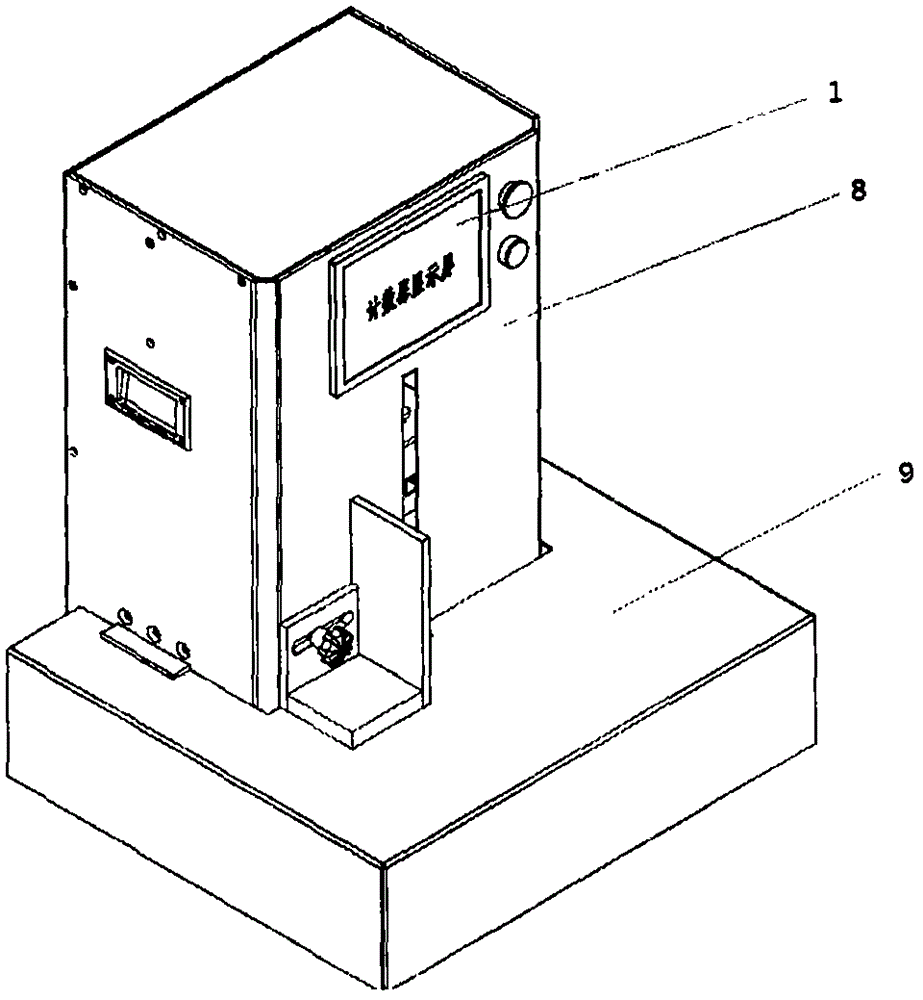

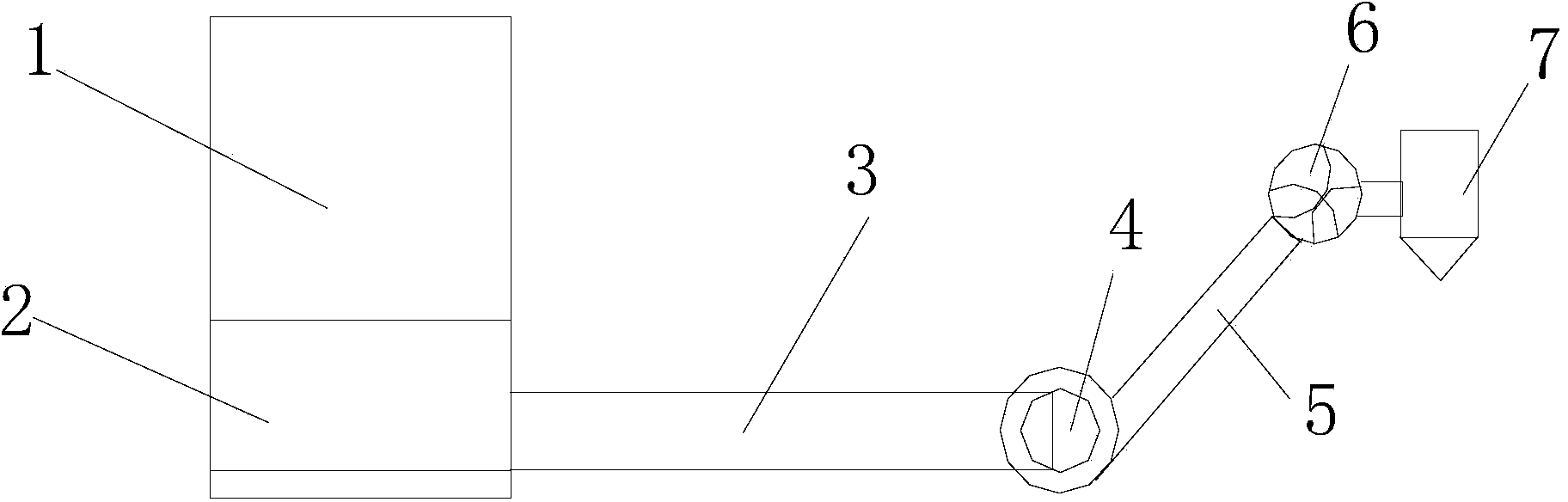

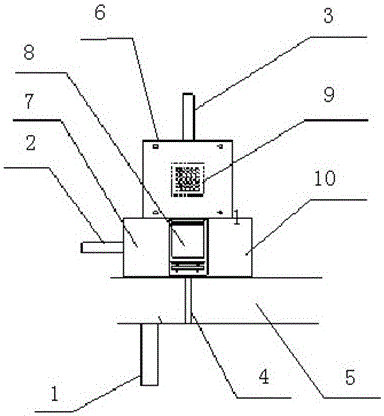

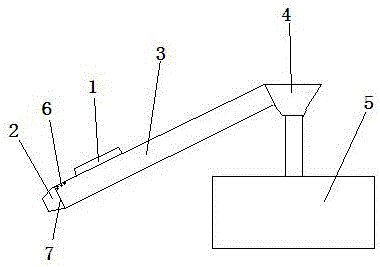

Method and device for accurate counting of papers depending on optoelectronic scanning

InactiveCN107437109ANo damageImprove scanning accuracyCounting objects on conveyorsHuman–machine interfaceSolenoid valve

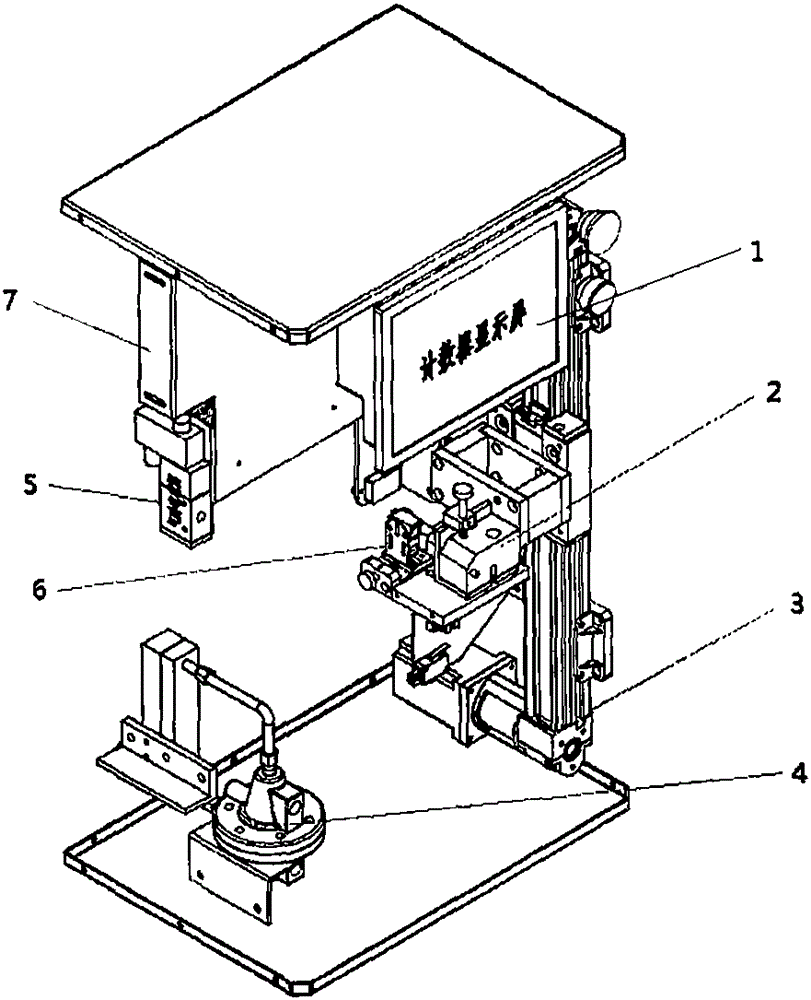

The present invention provides a method and device for accurate counting of papers depending on optoelectronic scanning. The optoelectronic scanning technology is employed, and the optoelectronic signal data of a paper lamination surface is collected to calculate the number of papers. A graph 1 is a system composition sketch map, wherein 1 is a human-computer interface display, 2 is a gas blowing system, 3 is a servo motion system, 4 is a gas current stabilization system, 5 is a solenoid valve, 6 is an optoelectronic scanning system and 7 is a central processing unit. The method and device for accurate counting of papers depending on optoelectronic scanning can be suitable for multiple products, such as a folding paper box, a paperboard, a cigarette case, a medicine box ,various composite materials, specification of a cartridge bag, a cartridge bag card, a postcard, a hard plastic card, a greeting card, a decoration card, a folding volume and the like. The method and device for accurate counting of papers depending on optoelectronic scanning have the advantages as follows: (1) non-contact scanning, wherein there is no damaging for a measured object; (2) high scanning precision and fast scanning speed; (3) no noise at work on the whole to improve the production work environment; and (4) simple operation to facilitate improving production efficiency and saving manpower cost.

Owner:北京弘浩千瑞科技有限公司 +1

Method for centralized collection and sorting treatment of shredded smoke in leaf laying process in threshing and redrying

The invention discloses a centralized collection and classified treatment system and method for crumbled tobacco of the leaf laying process in a threshing and redrying technology. The system comprises leaf laying tables, a crumbled tobacco collecting and separating unit, a slow-speed picking belt, a bundle breaking conveying belt and an air-conveying pipeline system; the leaf laying tables are arranged on multiple leaf laying stations respectively, and one end of each leaf laying table is provided with multiple crumbled tobacco collecting holes; the crumbled tobacco collecting and separating unit comprises a crumbled tobacco collecting and conveying belt, a vibrating separation device, the slow-speed picking belt and an electromagnetic three-stage vibrating screen. The crumbled tobacco produced in the leaf laying process is collected in a centralized mode through the crumbled tobacco collecting holes and conveyed to the vibrating separation device for separation, various impurities form clusters and the crumbled tobacco to be discharged, and by means of picking and impurity removing, the crumbled tobacco enters the three-stage vibrating screen for stage treatment. According to the centralized collection and classified treatment system and method for the crumbled tobacco of the leaf laying process in the threshing and redrying technology, by means of centralized collection and treatment of the crumbled tobacco of the leaf laying process and combination of the vibrating separation device and artificial picking, the content of the impurities in a product is reduced, the purity of tobacco leaves is improved, the technological purpose of removing the impurities for purifying is achieved, and resource waste is reduced.

Owner:BAOFENG REDRYING FACTORY OF TIANCHANG INT TOBACCO CO LTD

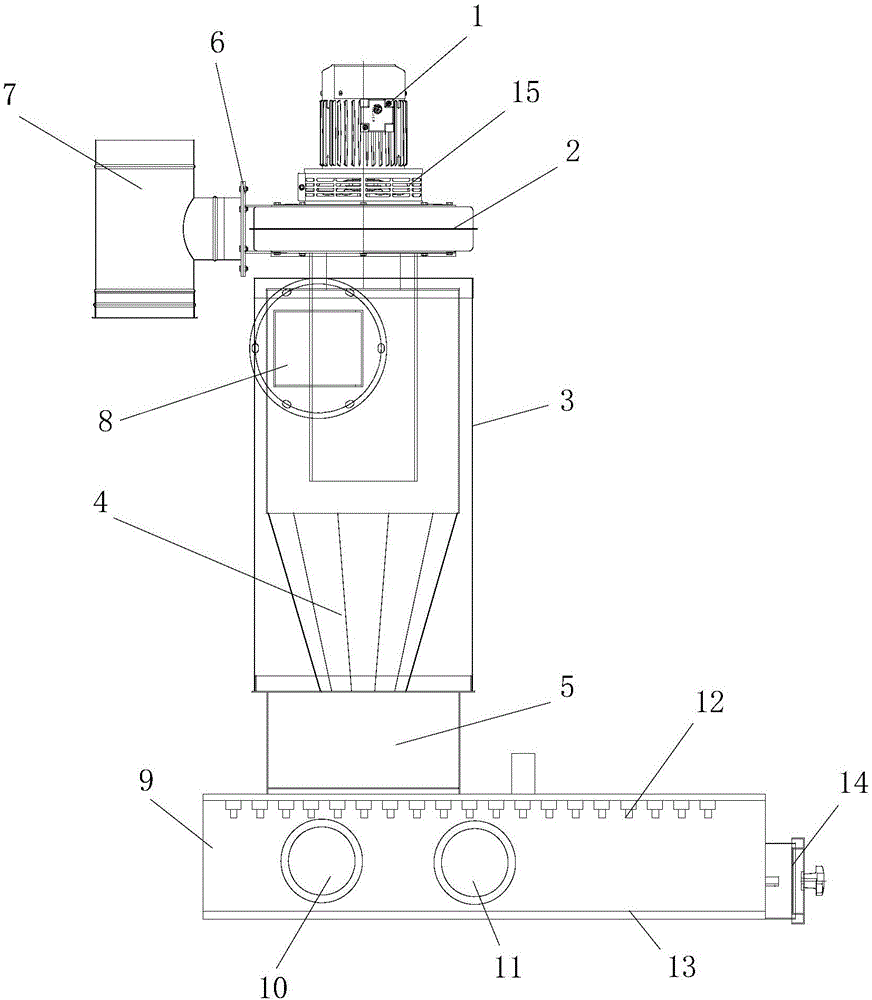

Boiler dust collector

InactiveCN104353294AReasonable structural designImprove dust removal effectDispersed particle filtrationDirt cleaningSlagWorking environment

The invention discloses a boiler dust collector. The boiler dust collector comprises a boiler and a slag warehouse which is arranged in the boiler; a dust suction pipe is arranged at the tail part of the boiler; the dust suction pipe comprises a cylinder body and an exhaust fan; the exhaust fan is positioned at the end part of the cylinder body and is connected with a crusher through a pipeline; a pulse-type cloth bag dust collector is arranged at the outlet of the crusher. According to the boiler dust collector disclosed by the invention, the dust removal effect is good; dust removal is performed on a transfer medium, especially on wind carrying dust, crusher raw material dust, or the dust generated in a processing process, dust explosion is prevented, the service cycle of the boiler dust collector is prolonged, meanwhile, the production and working environment of the boiler dust collector and personnel is thoroughly improved, the usage rate of the boiler dust collector is improved, the service life of the boiler dust collector is prolonged, the conveying process is simple, secondary dust removal is realized, the site environment is effectively improved, and moreover, the operating effect is good, and the manufacturing cost is low.

Owner:AMPHENOL CHANGZHOU ELECTRONICS

Boiler dust remover

ActiveCN106402913AImprove the production working environmentReasonable structural designLighting and heating apparatusDust explosionSpray nozzle

The invention relates to the field of boiler dust removing devices, in particular to a boiler dust remover. The boiler dust remover comprises a motor, a motor bellows, a dust box, a conical cloth bag and a collection box. The motor bellows is installed on the upper portion of the dust box and communicates with the conical cloth bag arranged inside the dust box. One side of the motor bellows communicates with an exhaust duct through a flange plate. One side of the dust box is provided with an air inlet pipeline. The collection box communicates with the lower portion of the dust box. The lower portion of the collection box is connected with a drying oven which is of a double-layer structure. A heat inlet and a heat outlet are formed in the side wall of the drying oven. Spraying nozzles are formed in the inside top wall of the drying oven. A collection plate is in sliding fit with the bottom of the drying oven and is connected with an oven door. The boiler dust remover is reasonable in structural design, good in dust removing effect, and capable of removing dust in delivery media, especially winnowing dust, dust in raw materials of a pulverizer and dust in a machining process, dust explosion is avoided, and the service cycle of equipment is prolonged.

Owner:TIANJIN KAI PUSEN HEATING EQUIP

Continuous automatic production system and method for component B of two-component silicone adhesive

PendingCN113398827ARealize continuous automatic productionShorten the timeMixer accessoriesContinuous/uninterruptedControl engineering

The invention provides a continuous automatic production system for a component B of a two-component silicone adhesive. The continuous automatic production system comprises a high-speed dispersion machine, a vacuum additive tank and a metering and mixing unit, the metering and mixing unit comprises multiple sections of metering and mixing assemblies which are connected in sequence, each metering and mixing assembly comprises a first metering cylinder, a second metering cylinder and a mixer, and the base material inlet end of the mixer of the later section of metering and mixing assembly is connected with the discharging port end of the mixer of the previous section through the first metering cylinder; and a base material inlet end of the mixer of the first section of metering and mixing assembly is connected with a discharge hole of the high-speed dispersion machine through a metering cylinder I; and an auxiliary agent inlet end of the mixer of each section of metering and mixing assembly is connected with a discharge hole end of the vacuum auxiliary agent tank through a metering cylinder II. According to the invention, through the design of the segmented metering and mixing units, the continuous and uninterrupted mixing of the component B base material and the component B auxiliary agent is completed, the continuous and automatic production of the component B of the two-component silicone adhesive is realized, and compared with the traditional intermittent production, a large amount of intermediate ring time is saved, and the production efficiency is obviously improved.

Owner:湖北通成高新材料有限公司

Low-cost low-temperature plastic dipping PVC glove forming process method

InactiveCN111592725ALow costHigh hardnessDomestic articlesCoatingsPolymer scienceIn situ polymerization

The invention belongs to the field of high polymer materials, and especially relates to a low-cost low-temperature plastic dipping PVC glove forming process method. The low-temperature plastic dippingPVC glove forming process method uses chloro-ether resin and allyl resin monomers, low-temperature plastic dipping of PVC gloves is realized through in-situ polymerization and synchronous crosslinking, the preparation cost is low, a hand mold does not need to be preheated, high temperature production environment is not needed, energy consumption is low, the production working environment and conditions are improved, the prepared PVC gloves are more durable, good in sealing performance, free of peculiar smell, large in elasticity, resistant to acids and alkalis, convenient and comfortable to wear, integrally formed, non-sticky, convenient and safe, free of natural latex allergic protein and free of anaphylactic reaction, and the strength, the corrosion resistance and the hygienic propertyare improved.

Owner:安徽攀望科技有限公司

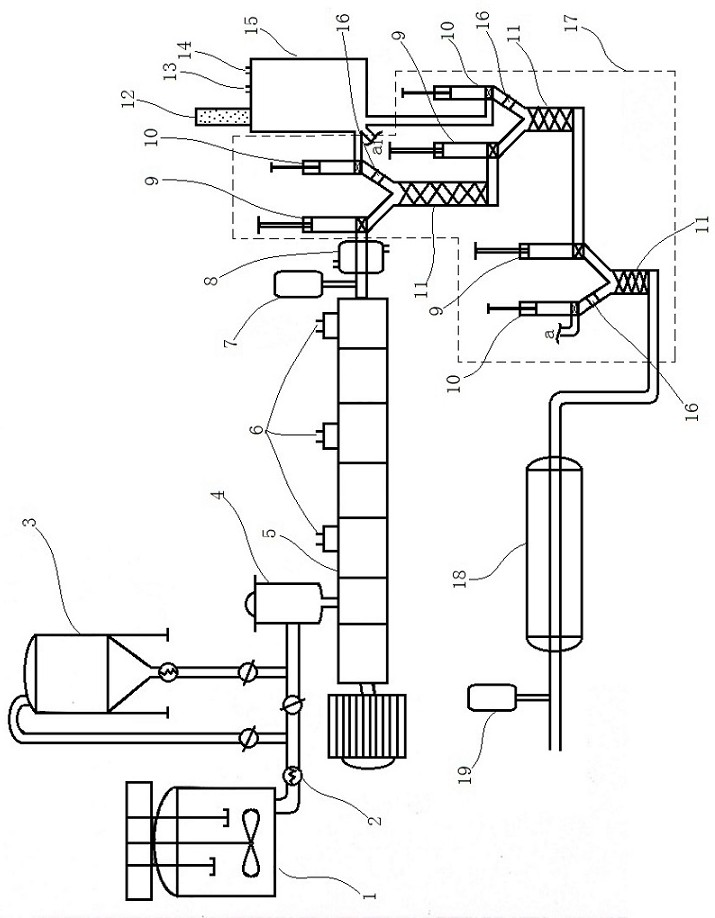

A coking tail gas treatment device

The invention discloses a coking tail gas treatment device to solve the problems of water vapor, malodorous gas pollution, secondary pollution caused by the discharge of tail gas VOC and coke powder along with the tail gas in the existing delayed coking device. The coking tail gas treatment device includes a tail gas treatment tower. The tail gas treatment tower is sequentially composed of a desaturation section, a desulfurization section, a gas-liquid separation section and a settling section from top to bottom. A desulfurization section oil collecting tank is arranged below the desulfurization section in the tail gas treatment tower. Below the gas-liquid separation section, there are coke tower tail gas and other equipment in the coking unit to generate tail gas injection pipeline, coke tank tail gas injection pipeline, coke tower discharge steam injection pipeline, and the bottom of the tail gas treatment tower is provided with washing sewage extraction pipeline The lower part of the settling section is provided with a washing water extraction bucket, the upper part of the desulfurization section is provided with an absorbing liquid injection line, the lower part of the desulfurization section oil collection tank is provided with a desulfurization section oil collection tank extraction outlet, and the top of the tail gas treatment tower is provided with a desaturated coking tail gas pipeline.

Owner:CHINA PETROLEUM & CHEM CORP +2

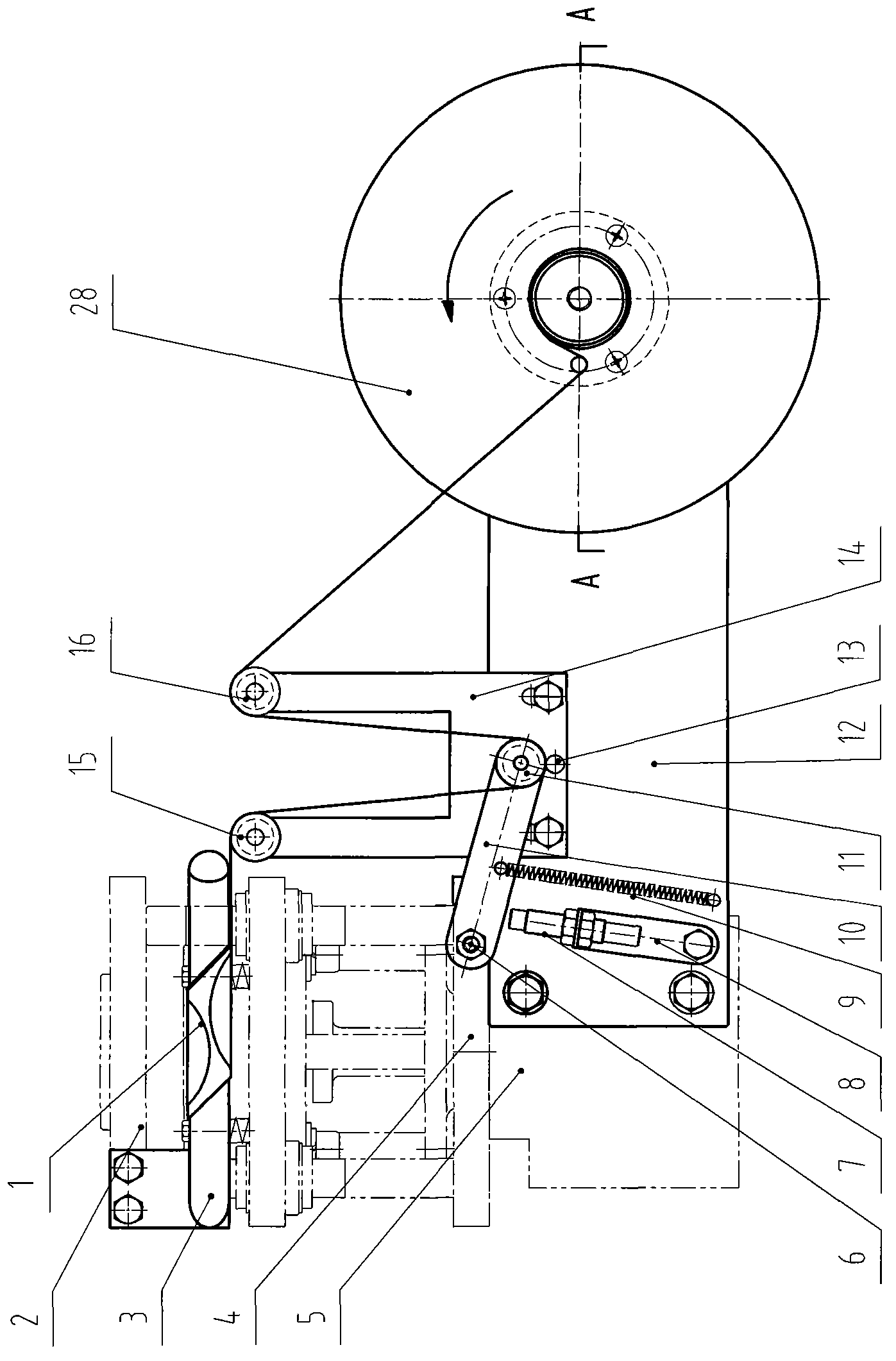

Waste paper recycling and rolling mechanism of paper cup machine

The invention relates to a waste paper recycling and rolling mechanism of a paper cup machine. The waste paper recycling and rolling mechanism comprises a waste paper recycling portion and a waste paper rolling portion. The waste paper recycling portion mainly comprises a reversing arm, a dowel, a light hole switch, a switch base, a tension spring, a swing arm, a compression roller, a support plate, a shift rod, a roller seat, a roller I, a roller II and the like. The waste paper rolling portion mainly comprises a motor, a motor seat, a bevel pinion, a main gear, a bearing, a bearing block, a roll paper sleeve, a roll paper ring, a paper retaining plate, a pretension rod, an adjusting nut, a knurling cap and the like. By adding the waste paper recycling and rolling mechanism into the paper cup machine, complicated waste paper treatment is easy and convenient. In addition, the waste paper recycling and rolling mechanism has the advantages that labor intensity of operators is alleviated, production and operating environment is improved, use functions of the machine are improved and the like.

Owner:瑞安市胜利机械有限公司

A water mill for removing smoke and dust

InactiveCN105664639BAvoid explosionImprove the production working environmentCombination devicesFlue gasWater circulation

A water mill smoke and dust removal device includes a cooling chamber, a separation chamber and a water mill chamber. Cooling water and a submersible pump are installed in the water pool. S-shaped cooling pipes are installed in the cooling water. In the separation chamber, the upper part of the dust inlet is installed The horizontal vibrating screen, the bottom of the separation chamber is equipped with a screw ash machine, the top of the separation chamber communicates with the top of the water mill through the air pipe, the exhaust fan, and the submersible pump in the pool communicates with the top of the water mill through the water pipe. For the water mill device, the lower part of the water mill chamber communicates with the water tank, the water tank communicates with the pool through a connecting pipe, and there is a flue gas outlet at the upper part of the water tank, and the flue gas outlet communicates with the purifier on the upper part of the cooling chamber through the flue gas pipe, and a cleaning exhaust is installed on the top of the cooling chamber trachea. The present invention is relatively thorough through four times of smoke removal and dust removal. Second, the water in the pool is recycled. The invention is particularly effective for boiler chimneys, hotel fume, or dust removal during processing.

Owner:常德市绿盛环保机械设备有限公司

A kind of automatic drug charging method and drug charging machine for combined fireworks production

InactiveCN103512436BImprove securityHigh degree of automationFireworksProcess developmentBiochemical engineering

Owner:HENAN LINXIAO SCI & TECH DEV

A kudzu root modification machine

ActiveCN104526750BAvoid production wasteIncrease production capacityMetal working apparatusEngineeringMechanical engineering

The invention relates to the field of food processing machines, in particular to a reshaping machine for kudzuvine roots. The reshaping machine comprises a saw installation body, a saw, a sawing platform capable of sliding transversely, an adjustable longitudinal positioning baffle and an adjustable transverse positioning baffle, wherein the saw is installed on the saw installation body, the sawing platform capable of sliding transversely is provided with an opening for moving of the saw and sliding of the platform, and the adjustable longitudinal positioning baffle and the adjustable transverse positioning baffle are installed above the sawing platform capable of sliding transversely. The reshaping machine can cut and reshape the kudzuvine roots well; the platform moves to complete cutting and reshaping, so that the safety degree of manual operation is increased, the defects of poor adaptability and poor safety of a common cutting machine in cutting and reshaping the kudzuvine roots are overcome, mechanization and industrialization of deep processing of kudzuvine root foods are facilitated, and development of the kudzuvine root industry is facilitated.

Owner:李政辉

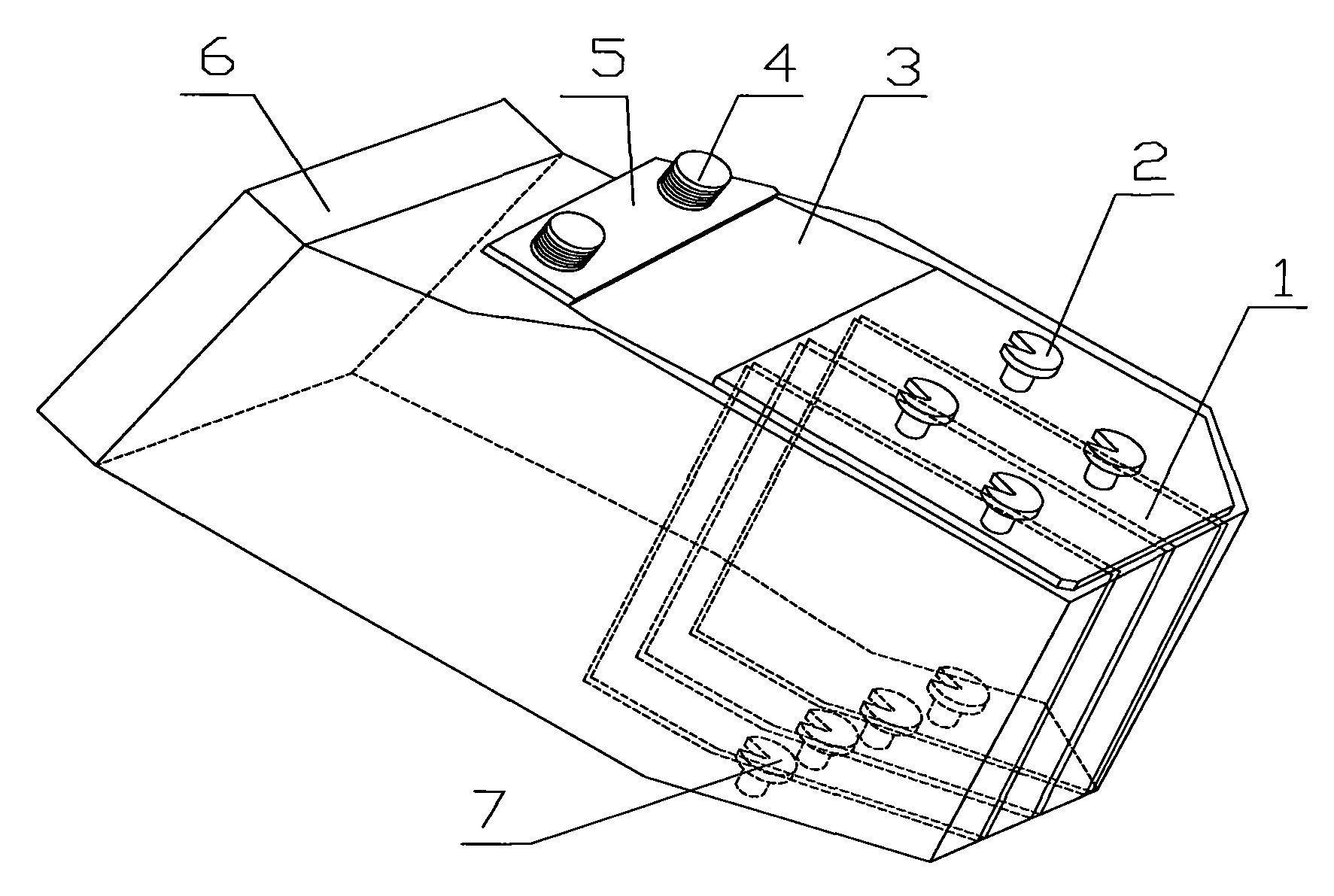

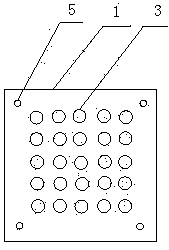

Carrier sheet template used for automatic assembling production of combined fireworks

The invention relates to the technical field of firework production equipment dies and discloses a carrier sheet template used for automatic assembling production of combined fireworks. The carrier sheet template is characterized by being composed of square or rectangular carrier sheet hole plates for installing a plurality of carrier sheets of the combined fireworks. Carrier sheet holes 2 which are evenly distributed in a square or rectangular or circular mode are formed in the centers of the square plates, wherein the distance between every two adjacent carrier sheet holes ranges from 10mm to 30mm. Annular steps 3 for supporting the carrier sheets are arranged in the centers of the carrier sheet holes 2. The carrier sheet template is a mechanically-produced die, can improve labor efficiency, is developed by improving and researching traditional firework production technologies, can achieve the purposes that factorization, mechanization, informatization, standardization and large scale combined firework production has the advantages of being safe and efficient, the number of participators is small, and the production environment is good, and can achieve the right-about-face of the development mode of the firework and cracker industry.

Owner:HENAN LINXIAO SCI & TECH DEV

Aromatic plastic material for plastic wire and preparation method thereof

ActiveCN104004261BSolve the bad plastic smellImprove the production working environmentProcedure AgentsPlastic materials

The invention discloses an aromatic plastic material for a plastic wire. The aromatic plastic material is prepared from the following components in percentage by mass: 35%-47% of ethylene-butylene copolymer, 1.5%-2.5% of silicone, 2%-20% of PP, 5%-15% of white oil, 3%-13% of processing aid, 5%-20% of filling agent, 0.5%-2% of porous ceramic framework material and 0.01%-0.1% of aromatic substance, wherein the porous ceramic framework material adsorbs and contains the aromatic substance. The invention further discloses a preparation method for the aromatic plastic material for the plastic wire. The preparation method comprises the steps of preparing materials, charging oil, stirring, extruding, cooling, pelletizing, and the like. The product disclosed by the invention can be used for storing the aromatic substance, so that an earphone product can release fragrance under usage and friction conditions, and can provide different fragrances according to needs of a consumer, and therefore, the problems that all plastic materials after being processed and formed are severe in plastic smell, strong in oil smell, and the like, are solved; the aromatic plastic material can be widely applied to manufacturing consumption type electronic product signal cable products such as earphone cable, and the like.

Owner:DONGGUAN YINGTONG WIRE +1

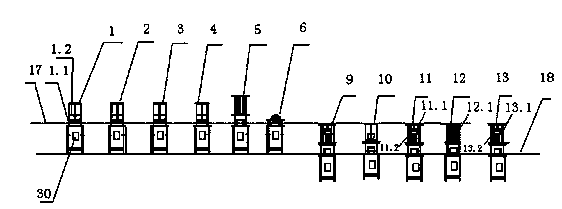

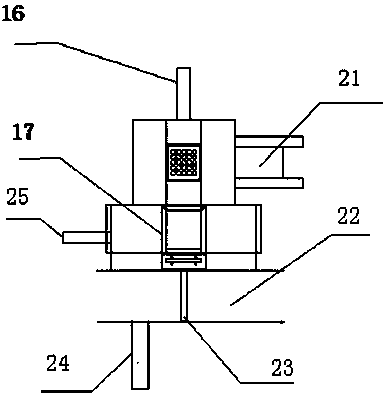

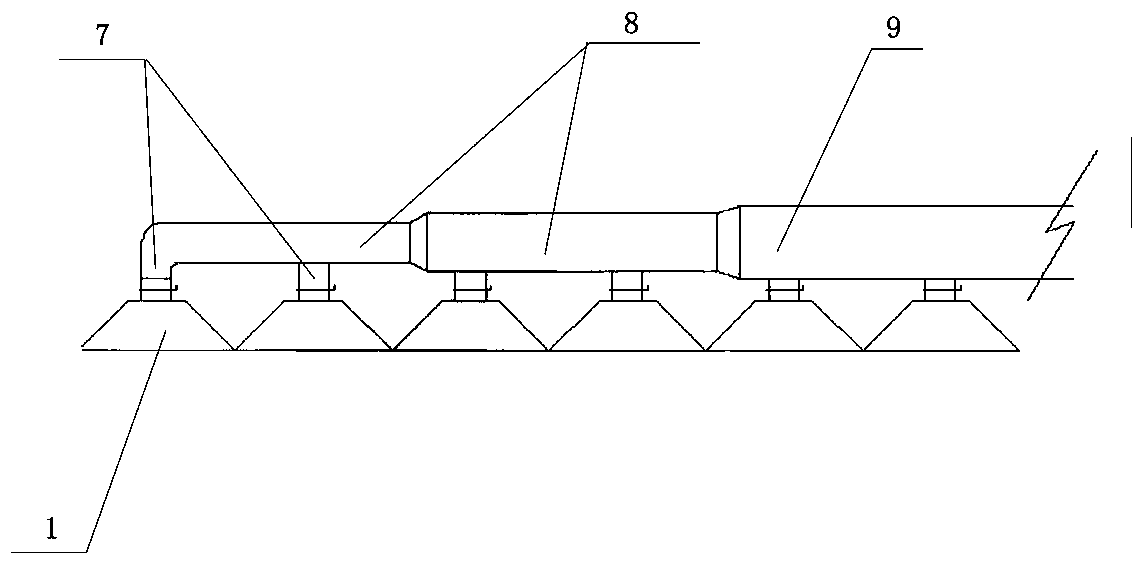

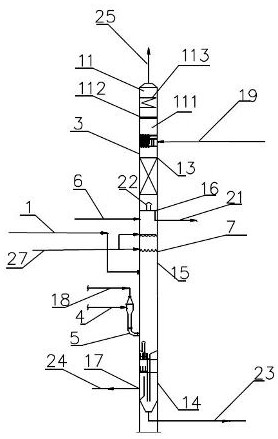

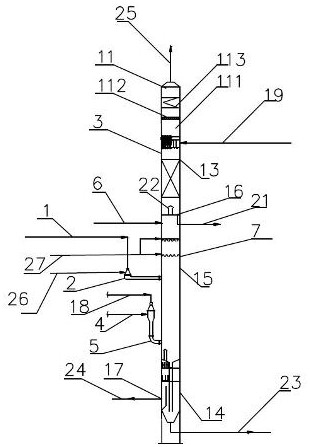

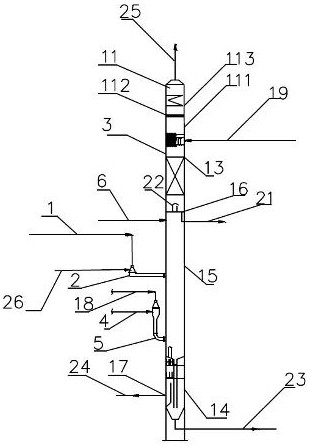

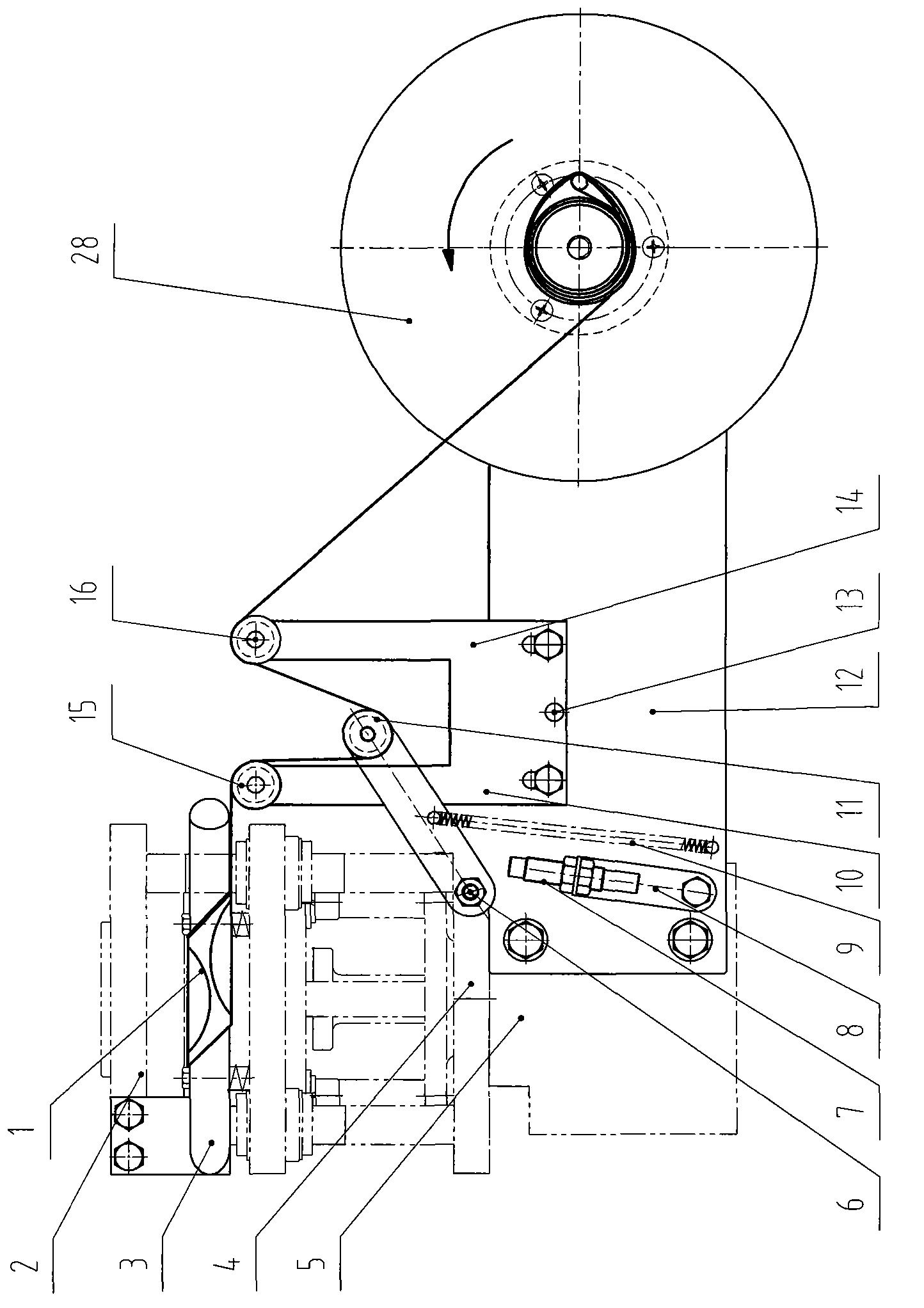

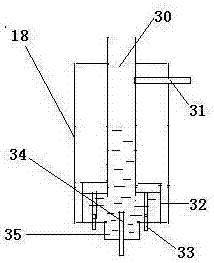

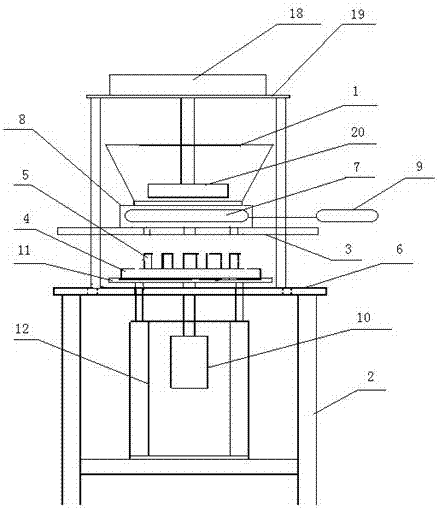

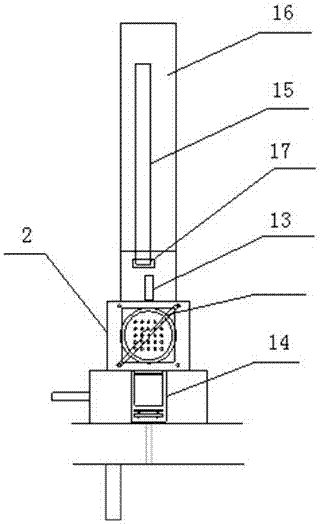

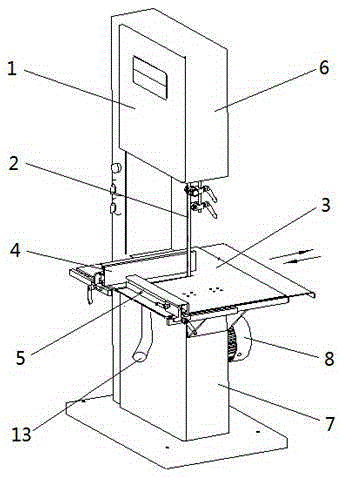

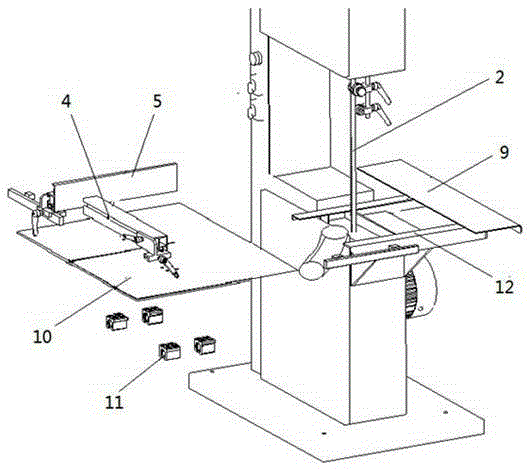

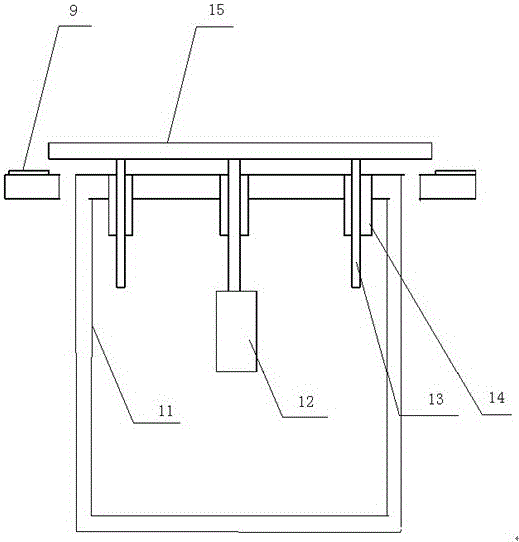

A method and device for entering and exiting assembly equipment for fireworks templates produced by combined fireworks

The present invention relates to the technical field of fireworks production, and discloses a device for entering and exiting assembly equipment for servo firework templates produced by combined fireworks, including: a device at the entrance of the assembly equipment is provided to send the firework template 18 into the explosion-resistant room by a conveyor belt 5 The workbench 9 at the starting position of the assembly and the entry and exit working mechanism for sending out the assembly equipment in the anti-explosion room; the lower part of the assembly equipment is provided with a lower lifting device for the firework template 18 to be pushed up from the workbench 9 at the starting position of the assembly to the assembly work position 16; The entry and exit working mechanism is composed of a horizontal mold push cylinder 1, a vertical mold push cylinder 2, a mold pull cylinder 3 and a baffle plate 4; the present invention can realize five modernizations: industrialization and mechanization through the improvement and research and development of traditional fireworks production technology , informatization, standardization and scale. It has the characteristics of high safety, less land occupation, high degree of automation, less manpower, high efficiency, and good production and working environment, realizing a fundamental change in the development mode of the fireworks and firecrackers industry.

Owner:HENAN LINXIAO SCI & TECH DEV

Dry type boiler slag removing device for power station auxiliary machine

InactiveCN106402906ASave on shipping partsAvoid device wear and tearLighting and heating apparatusAirflowPower station

A dry type boiler slag removing device for a power station auxiliary machine comprises a slag crusher, an air feeder, a conveying pipeline, a dust remover and a storage bin; the conveying pipeline is a columnar hollow cavity; the side, in the length direction, of the conveying pipeline is provided with an opening; the slag crusher throws slag materials into one end of the conveying pipeline through the opening; the air feeder is arranged at the end of the opening of the conveying pipeline; the portion, on the side of the opening, of the conveying pipeline is provided with the slag crusher; the other end of the conveying pipeline is connected with the dust remover; and the dust remover is an impulse type cloth bag dust absorbing device and is used for exhausting dust carried in the airflow released from the air feeder. The dry type boiler slag removing device for the power station auxiliary machine is a slag removing device with the beneficial effects of removing dust and preventing abrasion.

Owner:无锡市鑫德热电设备有限公司

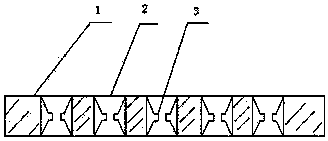

Outer barrel template used for combined automated firework assembly production

The invention relates to the technical field of firework production equipment moulds and discloses an outer barrel template used for combined automated firework assembly production. The outer barrel template is composed of outer-barrel outside frames 1 and outer-barrel inside frames 2 of a plurality of outer barrel pipe bodies used for mounting combined fireworks, the outer-barrel outside frames 1 and the outer-barrel inside frames 2 are square frames or rectangular frames, and the outer-barrel inside frames 2 are fixed on end faces of the outer-barrel outside frames 1; or the outer-barrel inside frames 2 are embedded in the outer-barrel outside frames. The outer barrel template is a mechanized production mould which is developed through improvement and research on a traditional firework production process, and has the advantages of capabilities of improving labor efficiency and realizing safety in use, fewer staff, high efficiency, a good production environment and the like for five normalization of factorization, mechanization, informatization, standardization and mass production of the the combined fireworks, and fundamental transformation of a firework industry development mode can be realized.

Owner:HENAN LINXIAO SCI & TECH DEV

Biomass particle boiler in-pipe dust removal device

InactiveCN106731287AAvoid explosionImprove the production working environmentDispersed particle filtrationTransportation and packagingAerospace engineeringFan blade

The invention relates to the field of a boiler dust removal device, in particular to a biomass particle boiler in-pipe dust removal device. The biomass particle boiler in-pipe dust removal device comprises a motor, a motor wind box, a dust collecting box, a conical cloth bag and a collecting bag, wherein the motor wind box is arranged at the upper part of the dust collecting box and communicates with the inside conical cloth bag; the output end of the motor is connected with fan blades arranged in the motor wind box; one side of the motor wind box communicates with an exhaust pipeline through a flange; one side of the dust collecting box is provided with an air inlet pipeline; the collecting box communicates with the lower part of the dust collecting box. Compared with the prior art, the biomass particle boiler in-pipe dust removal device has the advantages that the structural design is reasonable; the dust removal effect is good; the field environment is effectively improved; in addition, the operation effect is good; the manufacturing cost is low.

Owner:TIANJIN KAI PUSEN HEATING EQUIP

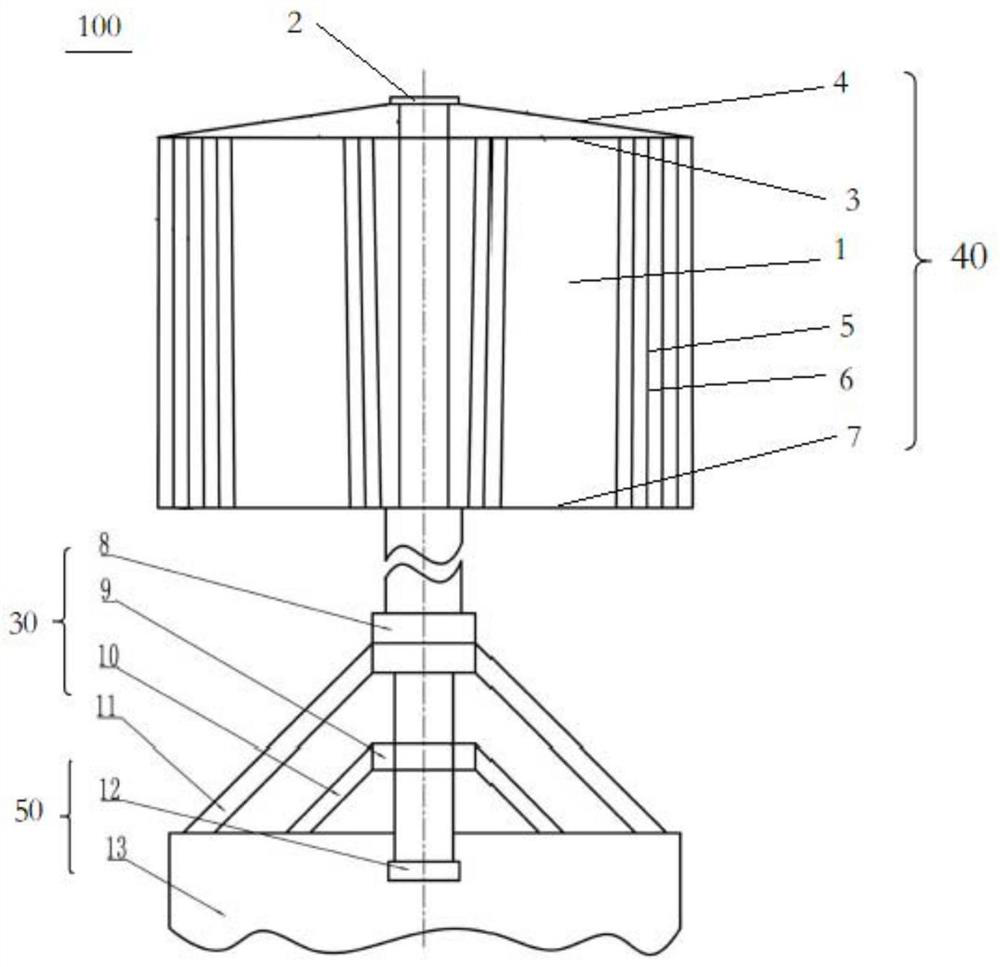

A wind drive system

ActiveCN110185582BThe structure of automatic pulp change is simpleReduce manufacturing costWind motor controlFinal product manufactureAir velocityClassical mechanics

The invention provides a wind power driving system. The wind power driving system comprises multiple groups of blade mechanisms and a rotary main shaft, wherein the multiple groups of blade mechanismsare rotatably arranged around a circle of the radius of the rotary main shaft; each group of blade mechanisms comprises blades and a rotary shaft assembly; the blades can be automatically variable inpitches and are mounted on the rotary shaft assembly; and each group of blade mechanisms synchronously rotate together with the rotary main shaft while locally rotating in a windward blowing action.The wind power driving system can automatically change the pitches to rotate without being driven by mechanical power under the wind speed of strong wind from grade 2 to grade 10; the rotation directions of the wind wheel blades and wind wheels are independent of the wind direction and the wind speed; and the automatic pitches changing structure of the wind wheel blades is simple, the blades can be mass produced, the production cost is reduced, and the production working environment is improved to the maximum extent.

Owner:SANMING UNIV

Complete device for treating acid mist through bottom air draft of electrolysis workshop

PendingCN111074304AImprove the production working environmentReduce erosionGas treatmentElectrolysis componentsElectrolysisThermodynamics

The invention provides a complete device for treating acid mist through bottom air draft of an electrolysis workshop. The complete device comprises the electrolysis workshop, electrolysis tanks in theelectrolysis workshop, independent gas chambers below the electrolysis tank and a waste gas treatment assembly which is connected with the independent gas chambers, the periphery of the electrolysisworkshop is sealed without ventilation holes, skylights for air inflow are formed in the top of the electrolysis workshop, each independent gas chamber is a space formed by the bottom face of the corresponding electrolysis tank and the floor, and the periphery of each independent gas chamber is sealed. The waste gas treatment assembly comprises exhaust columns on the bottoms of the independent gaschambers, blowers connected with the exhaust columns or the independent gas chambers and washing towers connected with air outlets of the blowers, and exhaust chimneys communicated with air are arranged on the tops of the washing towers. By means of the complete device, the problems are solved that in the process of treating the acid mist in the electrolysis workshop, the acid mist treatment effect is poor, and the acid mist can cause harm to the body health of operators in the acid mist treatment process.

Owner:河南菲迪泰环境科技有限公司

Coking tail gas treatment process and coking tail gas treatment device

The invention discloses a coking tail gas treatment process and a coking tail gas treatment device. A purpose of the invention is to solve the problems of secondary pollution and the like caused by vapor and malodorous gas pollution and tail gas VOC and coke powder discharge along with tail gas of the existing delayed coking device. According to the device, coke pool tail gas, coke tower dischargesteam, coke tower tail gas and tail gas generated by other equipment in a coking device enter the gas-liquid separation section of a tail gas treatment tower and are subjected to gas-liquid separation; the gas-phase coking tail gas rises to a desulfurization section and is in countercurrent contact with an absorption liquid entering from the upper portion of the desulfurization section so as to be desulfurized; the desulfurized coking tail gas continuously rises to reach a desaturation section; after desaturation, the tail gas is discharged from the top of the tail gas treatment tower, VOC isremoved, and then the tail gas is emptied; the rich absorption liquid is pumped out, pressurized and returned to the upper portion of the desulfurization section; after failure, the waste liquid is externally sent to a treatment unit; and the washing water containing solid particles in the tail gas treatment tower enters a settling section downwards, the washing sewage containing solid particlescomes out from the bottom of the tail gas treatment tower, and the clarified washing water comes out from a washing water pumping hopper at the lower portion of the tail gas treatment tower and is pressurized so as to be recycled as circulating washing water.

Owner:CHINA PETROLEUM & CHEM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com