Printing and dyeing wastewater afterheat recovery device

A waste heat recovery device, printing and dyeing sewage technology, applied in the direction of heating devices, water heaters, fluid heaters, etc., can solve the problems of energy saving and emission reduction, cost reduction, heat energy loss of printing and dyeing sewage, hindering development momentum, etc., and achieve improvement Production working environment, reducing human resource input, improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

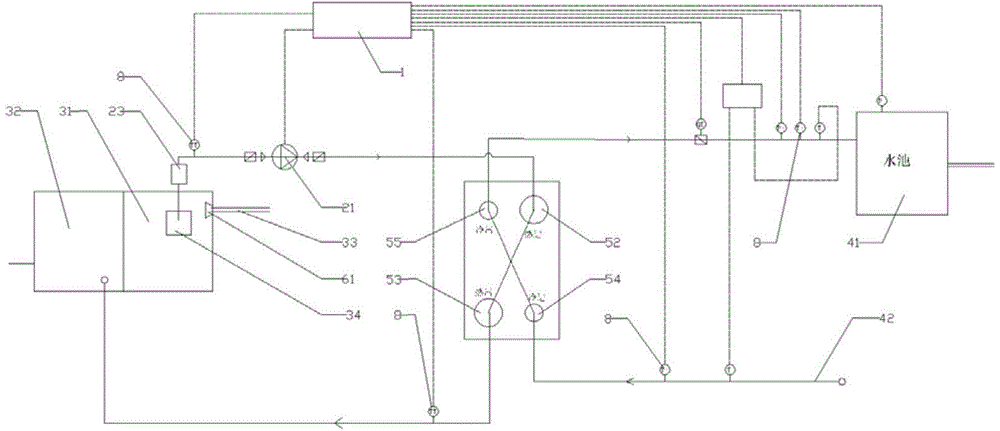

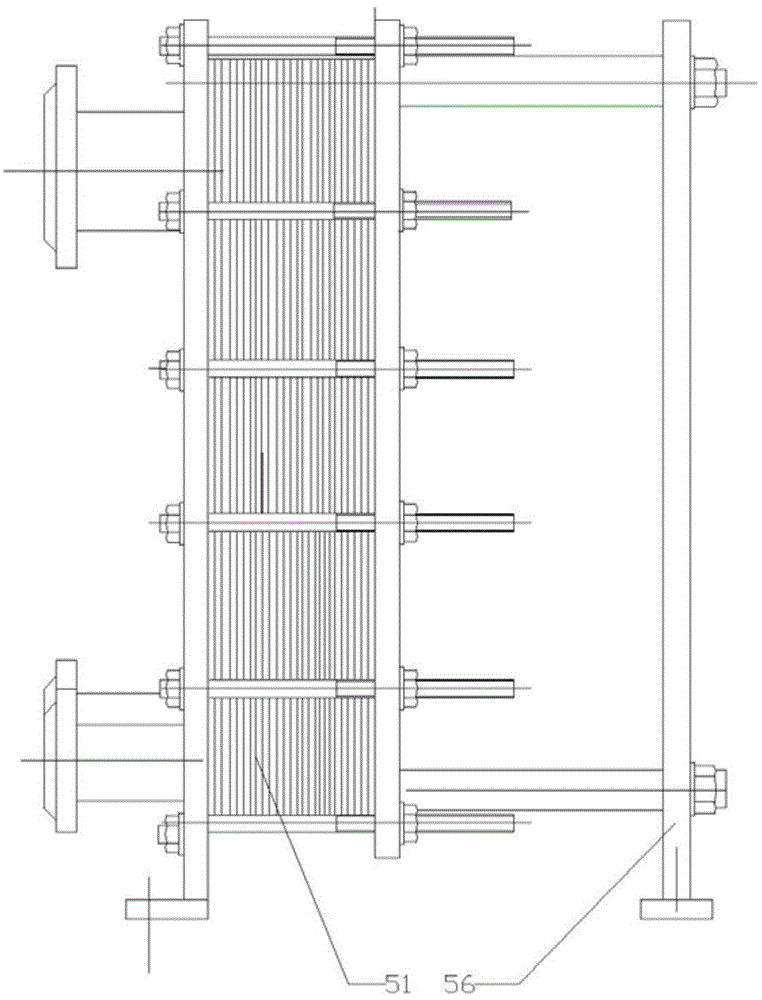

[0022] like figure 1 , image 3 , Figure 4 , Figure 5 As shown, in this embodiment, the waste heat recovery device for printing and dyeing sewage includes a sewage tank, a water pump I21, and an on-site control cabinet 1. The water pump I21 is electrically connected to the on-site control cabinet 1, and is provided by the water pump I21. The power of sewage circulating in the hot water channel. The sewage pool includes a heat recovery front pool 31 and a heat recovery rear pool 32. The heat recovery front pool 31 is used as a high-temperature sewage container for storing high-temperature sewage directly discharged by printing and dyeing equipment , to prepare for the next step of heat exchange recovery, the heat recovery rear pool 32 is used as a container for the sewage after heat exchange recovery, the heat recovery front pool 31 is provided with a sewage water inlet 33, and the heat recovery front pool 31 The position of the sewage water inlet 33 is provided with a wat...

Embodiment 2

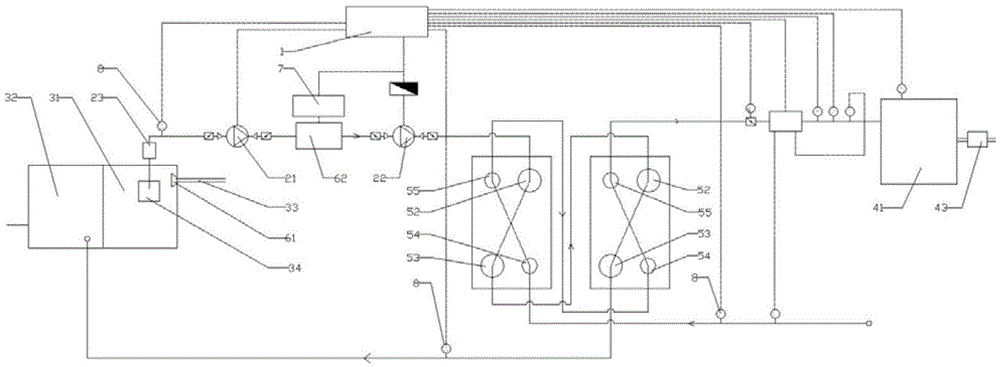

[0026] like figure 2 As shown, in this embodiment, the present invention includes two interconnected waste heat recoverers, the sewage heat exchange flow channel of the former waste heat recovery device is connected with the sewage heat exchange flow channel of the latter waste heat recovery device, and the former waste heat recovery device The clean water heat exchange channel of the waste heat recovery device is connected with the clean water heat exchange channel of the next waste heat recovery device. temperature for secondary heat exchange to recover heat, so as to achieve a more sufficient effect of heat exchange; the waste heat recovery device can be selected according to actual requirements during implementation, it can be one, or two or more connected, generally Two are preferred in the situation, which can not only effectively control the cost and process difficulty, but also fully recover the heat of sewage for heat exchange. In this example, the temperature of cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com