Waste gas treatment system of coated sand workshop

A technology of waste gas treatment and coated sand, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, etc., can solve problems such as the great impact on the production environment, reduce production safety hazards, improve work efficiency, and structure Make up a reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

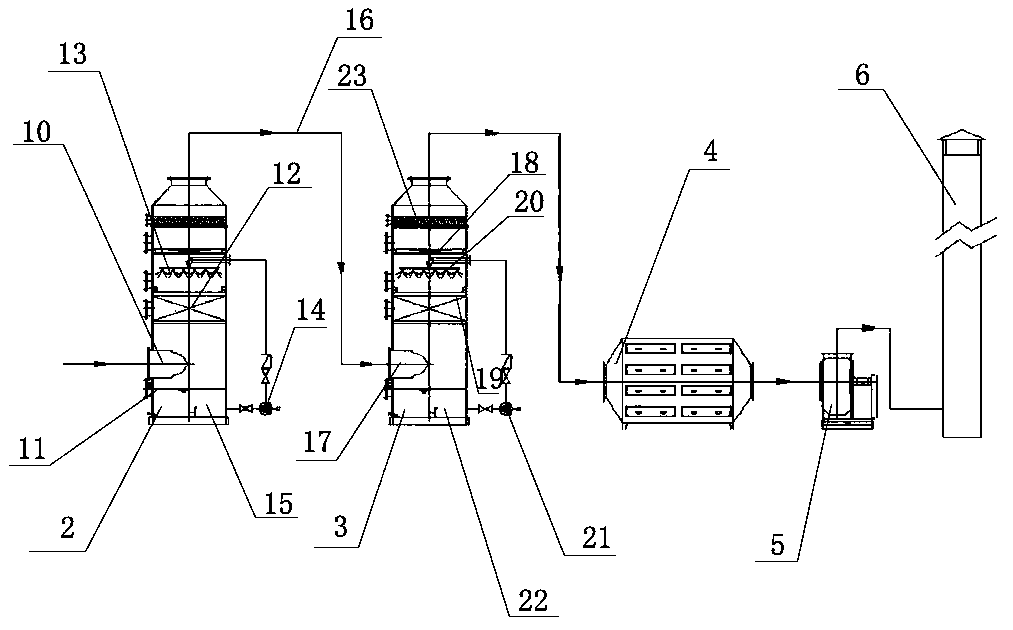

[0011] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, the exhaust gas treatment system of a coated sand workshop according to the present invention includes a plurality of top-suction exhaust gas collection hoods 1 installed in the production workshop, and the top-suction exhaust gas collection hoods 1 pass through the pipeline The system is connected to the swirl plate tower 2 for dust removal, and the back of the swirl plate tower 2 is connected with the packed tower 3 for oxidation, dissolution and neutralization and the activated carbon box 4 for adsorption and treatment, and the fan connected to the back of the activated carbon box 4 5 Connect the discharge chimney 6.

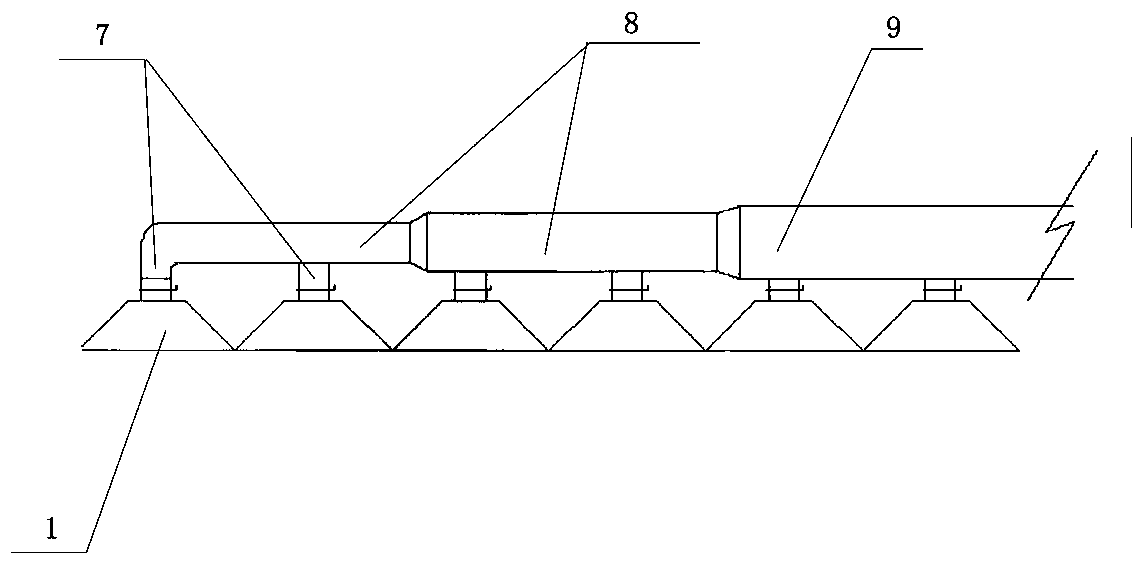

[0012] As shown in the figure, the top-suction collection hood 1 is a conical gas collection hood, and its upper part is connected to the middle pipe 8 by the respective branch pipes 7 or externally connected to the swirl plate towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com