A kudzu root modification machine

A kudzu root modification machine and installation box technology, which is applied in metal processing and other directions, can solve problems such as unfavorable kudzu root food deep-processing mechanization, industrialization, kudzu root dust pollution, kudzu root production waste, etc., to improve the production working environment and avoid skewed sawing roads , to avoid the effect of production waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments for realizing the present invention will be further described with reference to the accompanying drawings.

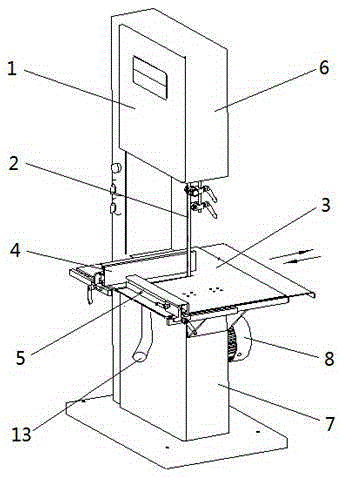

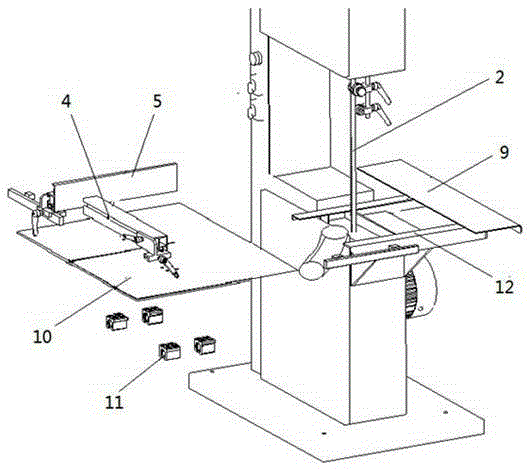

[0014] Such as figure 1 , figure 2 As shown, a kudzu root modification machine includes: saw body installation body 1, saw body 2, horizontal sliding sawing platform 3, adjustable longitudinal positioning baffle 4, adjustable lateral positioning baffle 5, saw body installation body 1 includes: the upper end installation box 6 of the saw body, the lower end installation box 7 of the saw body, the saw body driving motor 8, the upper and lower ends of the saw body 2 are respectively installed on the upper end installation box 6 of the saw body and the lower end installation box 7 of the saw body, the saw body The middle part of the lower end installation box 7 is equipped with a saw body driving motor 8, and the horizontally sliding sawing platform 3 is located above the lower end installation box 7 of the saw body, and the horizontal sliding sawing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com