Method and device for accurate counting of papers depending on optoelectronic scanning

A photoelectric scanning and precise counting technology, applied in the direction of counting objects, counting mechanisms/items, items shipped through conveyors, etc., can solve the problems affecting the production workshop environment, low work efficiency, difficult maintenance, etc., to improve production. Working environment, saving labor costs, high scanning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

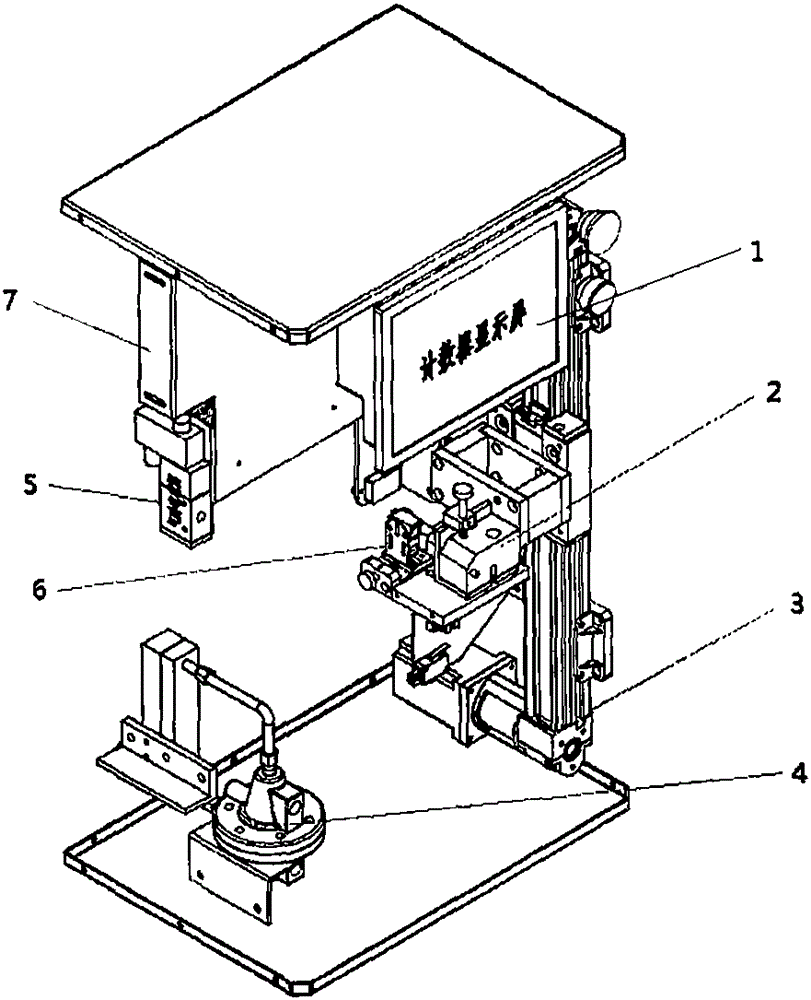

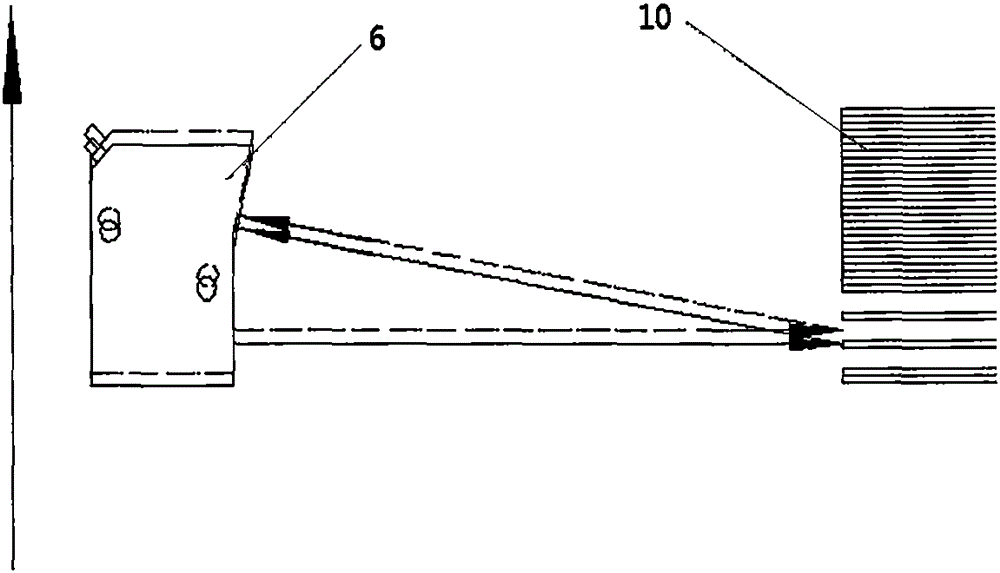

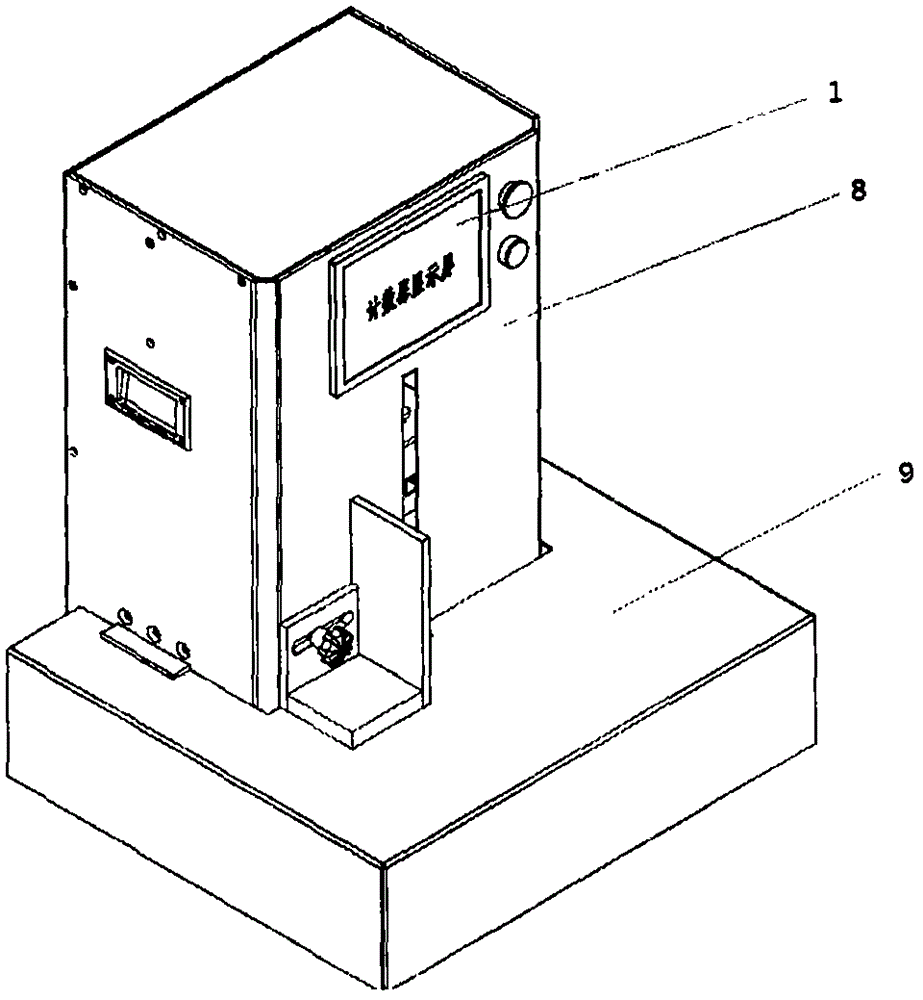

[0021] A method and device for accurately counting paper sheets relying on photoelectric scanning. The device of the present invention figure 1 Middle: 1 is the man-machine interface display, 2 is the air blowing system, 3 is the servo motion system, 4 is the gas steady flow system, 5 is the solenoid valve, 6 is the photoelectric scanning system, 7 is the central processing unit; figure 2 8 is the main support structure, and 9 is the operating platform; image 3 10 is the paper to be tested.

[0022] Counting mainly adopts photoelectric scanning technology, and calculates the number of paper by collecting photoelectric signal data on the stacked layer of paper. The specific operation steps are as follows:

[0023] The first step is to put a step of paper on the operating platform 9 and close to the front panel of the main support structure 8 .

[0024] In the second step, after the system detects that there is paper placed on the operating platform, the servo motion system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com