A coking tail gas treatment device

A technology for tail gas treatment and coking tail gas, which is applied to combined devices, chemical instruments and methods, separation methods, etc., can solve problems such as pollution, secondary pollution, and tail gas leakage, achieve simple processes and equipment, and save investment and floor space. , Strengthen the effect of gas-liquid separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

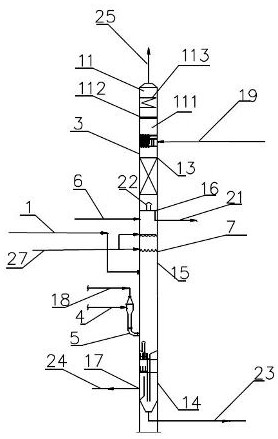

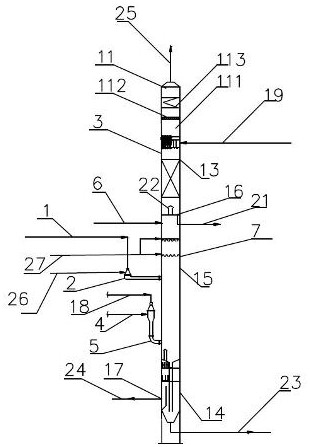

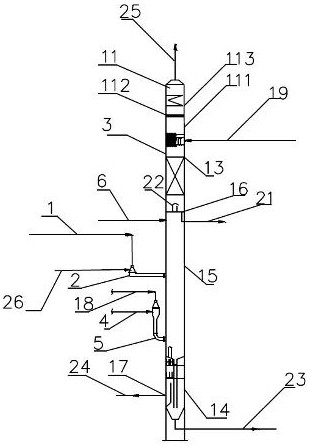

[0029] like figure 1 As shown, a coking tail gas treatment device, in figure 1Among them, the coking tail gas treatment device includes a tail gas treatment tower 3, and the tail gas treatment tower 3 includes a desaturation section 11, a desulfurization section 13, a gas-liquid separation section 15 and a settling section 14 in order from top to bottom. Under the desulfurization section in the tail gas treatment tower, there is a desulfurization section oil collecting tank 22, and below the desulfurization section oil collecting tank 22, a coke tower tail gas and other equipment in the coking device are installed at the gas-liquid separation section 15. The tail gas injection pipeline 6, the coke pond tail gas injection Pipeline 1, coke drum discharge steam injection line 4, coke drum tail gas and other equipment in the coking unit produce tail gas injection line 6, coke pond tail gas injection line 1, coke drum discharge steam injection line 4 along the tail gas treatment to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com