Boiler dust collector

A technology for dust collectors and boilers, which is applied in the fields of smoke removal, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of workers' health hazards, environmental pollution, and large dust, so as to prolong the service life of equipment, prevent dust explosions, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

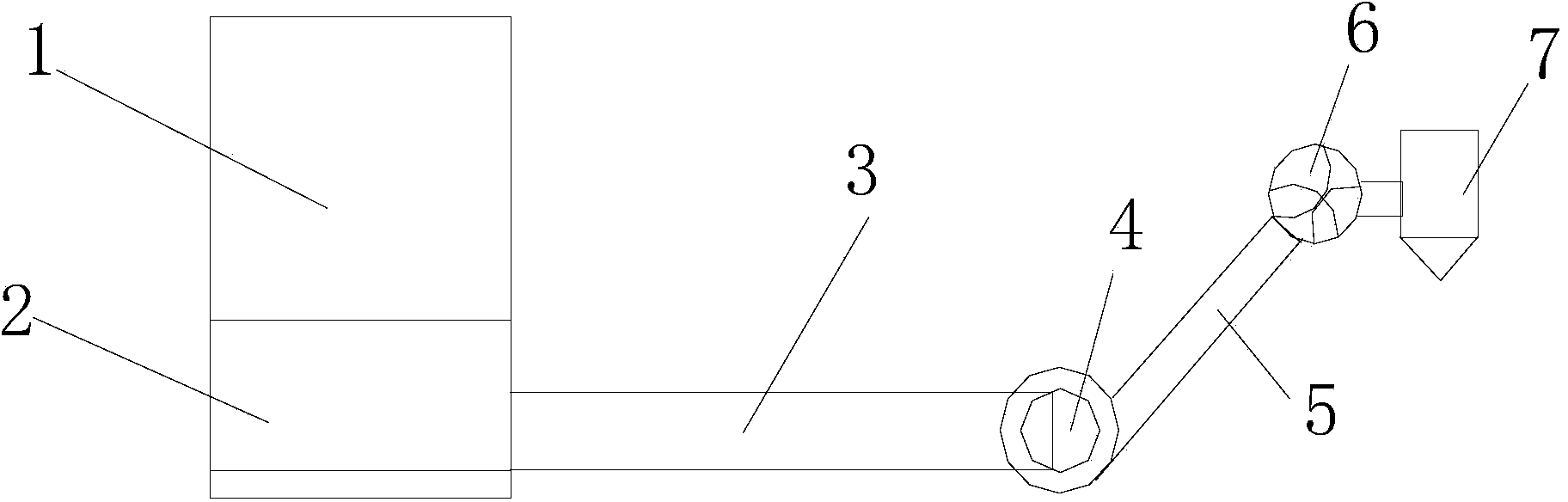

[0010] Such as figure 1 A boiler dust collector shown includes a boiler 1 and a slag bin 2 arranged in the boiler 1, and a dust suction pipe is provided at the tail of the boiler 1, and the dust suction pipe includes a cylinder body 3 and an exhaust fan 4. The exhaust fan 4 is located at the end of the cylinder body 3, and the exhaust fan 4 is connected to a pulverizer 6 through a pipeline 5, and a pulse bag vacuum cleaner 7 is arranged at the outlet of the pulverizer 6.

[0011] The boiler dust collector of the present invention has reasonable structural design and good dust removal effect, and is aimed at removing dust from the transmission medium, especially for wind-transported dust, the dust is first transported to the pulverizer through the exhaust fan, and the raw material of the pulverizer is dedusted, or for the dust in the processing process Dust removal, prevent dust explosion, prolong the service life of the equipment, and at the same time completely improve the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com