A water mill for removing smoke and dust

A technology of dust removal device and water mill, which is applied in the field of smoke removal, gas removal equipment, and dust removal. It can solve the problems of incomplete filtration and dust removal, low dust removal capacity of the bag filter system, and can not be achieved, so as to improve the utilization rate and service life of the equipment, Improve the production working environment and prevent dust explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

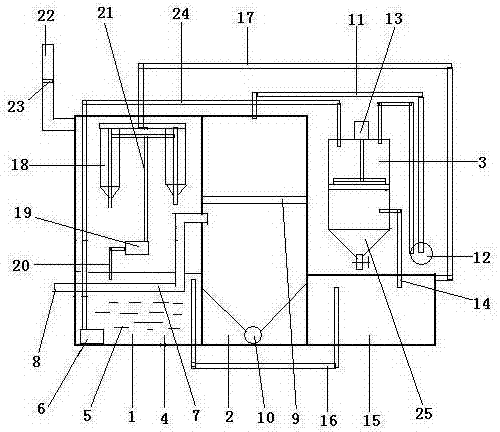

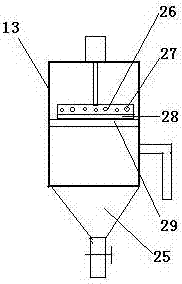

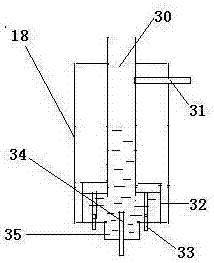

[0018] Such as figure 1 As shown, this water mill smoke and dust removal device includes a cooling chamber 1, a separation chamber 2 and a water mill chamber 3. The lower part of the cooling chamber 1 is a pool 4, and the pool 4 is equipped with cooling water 5 and a submersible pump 6. In the cooling water 5 An S-shaped cooling pipe 7 is installed, one end of the cooling pipe 7 is connected to the dust inlet 8, and the other end of the cooling pipe 7 is connected to the middle part of the separation chamber 2. In the separation chamber 2, a horizontal vibrating screen is installed on the upper part of the dust inlet 9. A screw ash discharger 10 is installed at the bottom of the separation chamber 2. The top of the separation chamber 2 communicates with the top of the water mill chamber 3 through the air duct 11, the exhaust fan 12, and the submersible pump 6 in the pool 4 communicates with the top of the water mill chamber 3 through a water pipe. , a water mill device 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com