Inner barrel template used for automatic assembling production of combined fireworks

A combination of fireworks and inner cylinder technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of simple workmanship, low labor efficiency, complex process, etc., and achieve the effect of eliminating occupational hazards, ensuring safe production, and realizing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

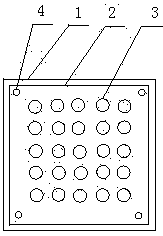

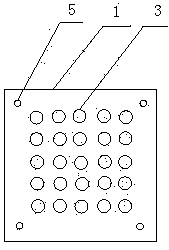

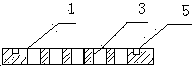

[0023] Such as Figure 1 to Figure 5 As shown, an inner tube formwork for the automatic assembly and production of combined fireworks is composed of inner tube orifice plates 1 and supporting plates 2 for installing a plurality of inner tube bodies of combined fireworks, and the inner tube orifice plate 1 is a square plate Or a rectangular plate, the square plate or the central part of the rectangular plate is provided with a square arrangement of uniformly distributed inner tube holes 3, or a rectangular arrangement of inner tube holes, or a circular arrangement of inner tube holes, or an elliptical arrangement of inner tubes Tube holes: the distance between two adjacent inner cylinder tube holes is 10 to 30 mm, and the four corners of the inner cylinder orifice plate 1 are provided with positioning pin holes 4 corresponding to the positioning pins 5 provided at the four corners of the supporting plate. The diameter of the inner tube hole 3 on the inner tube orifice plate 1 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com