Aromatic plastic material for plastic wire and preparation method thereof

A plastic material and aromatic technology, applied in the field of aromatic plastic material for plastic wire and its preparation, can solve the problems of staff and consumers, serious plastic smell, heavy oil smell, etc., so as to reduce production cost and improve experience. and satisfaction, the effect of reasonable and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

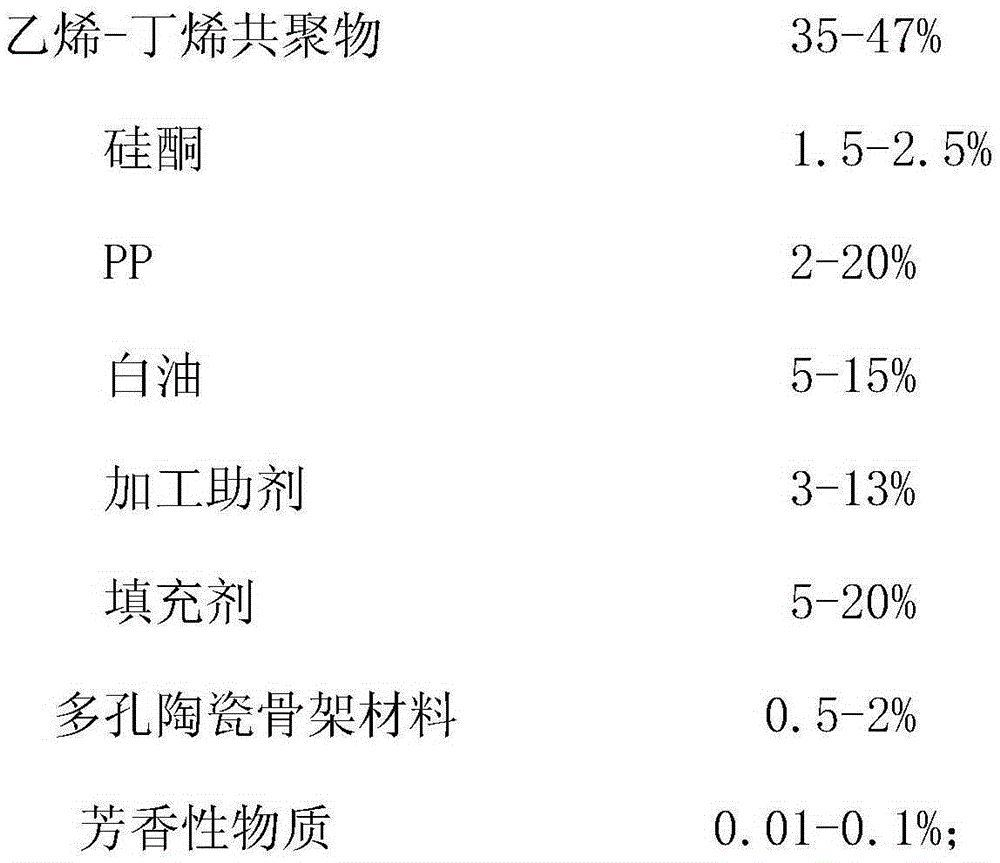

[0034] The aromatic plastic material for plastic wire provided in this example is processed from the following raw materials in mass percentage:

[0035]

[0036] The aromatic substances mentioned therein are adsorbed in the porous ceramic skeleton material.

[0037] The porous ceramic framework material is a polycrystalline ceramic framework material.

[0038] The aromatic substance is one of esters, alcohols, and aldehydes containing volatile aroma, or a mixture of several of them.

[0039] The processing aid is pentaerythritol ester; the filler is one or both of calcium carbonate and talcum powder.

[0040] A preparation method of the above-mentioned aromatic plastic material for plastic wire rods, the specific steps are as follows:

[0041] (1) Prepare a porous ceramic framework material and an aromatic gas, and make the aromatic gas adsorb in the pores of the porous ceramic framework material;

[0042] (2) Weigh the raw materials according to the following setting r...

Embodiment 2

[0053] The aromatic plastic material for plastic wire provided in this embodiment and the preparation method thereof are basically the same as in Embodiment 1, except that:

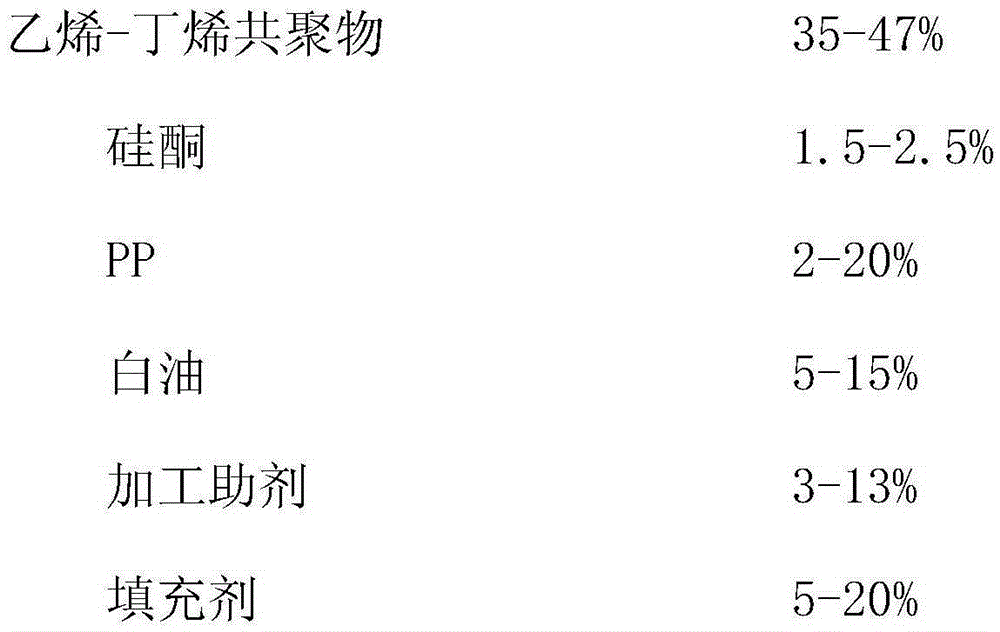

[0054] An aromatic plastic material for plastic wires, which is made of the following raw materials in mass percentage:

[0055]

[0056] The aromatic substances mentioned therein are adsorbed in the porous ceramic skeleton material.

[0057] The porous ceramic framework material is a polycrystalline ceramic framework material.

[0058] The aromatic substances are esters containing volatile aromatic odors.

[0059] The processing aid is pentaerythritol ester; the filler is one or both of calcium carbonate and talcum powder.

[0060] A preparation method of the above-mentioned aromatic plastic material for plastic wire rods, the specific steps are as follows:

[0061] (1) Prepare a porous ceramic framework material and an aromatic gas, and make the aromatic gas adsorb in the pores of the porous ceram...

Embodiment 3

[0073] The oil-resistant PVC material for plastic wires provided in this example and its preparation method provided in this example are basically the same as those in Examples 1 and 2, except that:

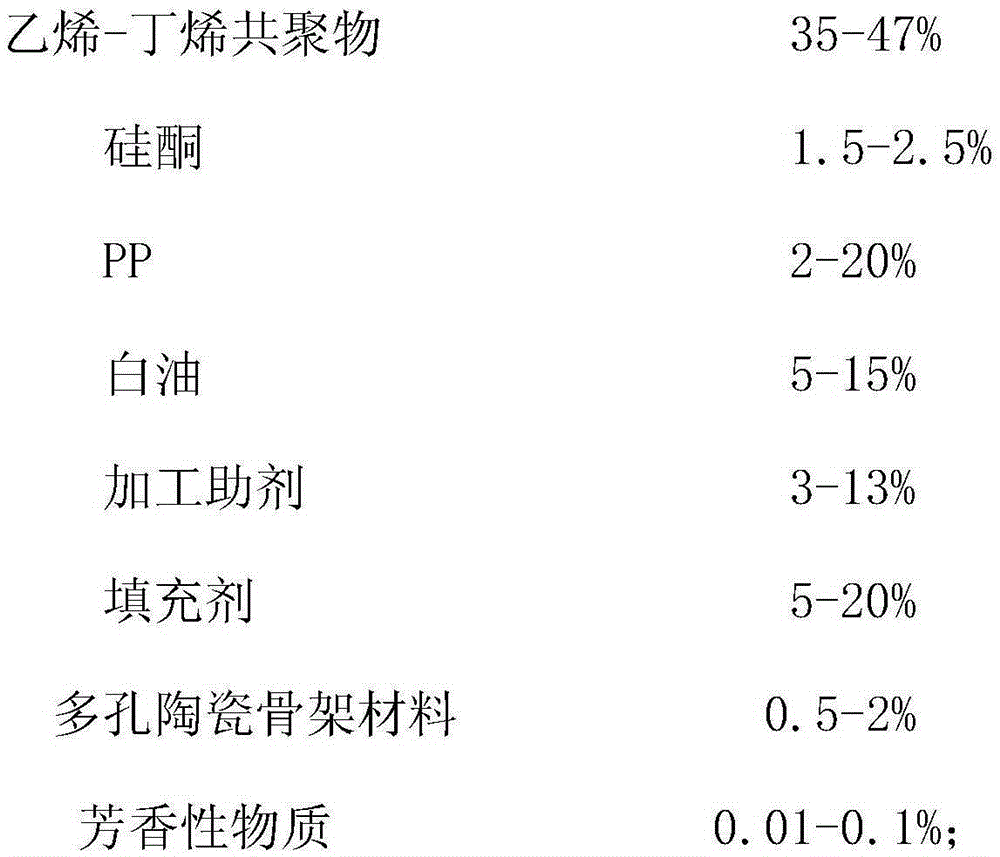

[0074] An aromatic plastic material for plastic wires, which is made of the following raw materials in mass percentage:

[0075]

[0076] The aromatic substances are aldehydes containing volatile aromatic odors;

[0077] A method for preparing an aromatic plastic material for plastic wires described above, the difference being: stirring temperature 40°C; kneading temperature 150°C; circulating water cooling temperature 7°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com