Automatic assembly method and assembly machine of inner barrels and outer barrels for producing combination fireworks

A technology that combines fireworks and automatic assembly. It is applied in the directions of fireworks, offensive equipment, and weapon types. It can solve the problems of simple workshops, low labor efficiency, and danger, and achieve the effect of good production and working environment, high degree of automation, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

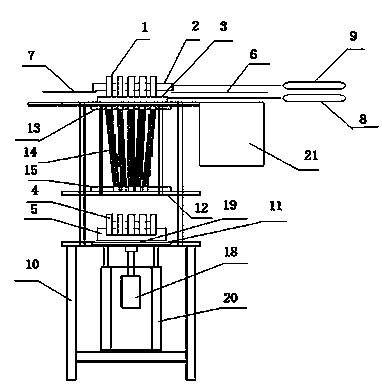

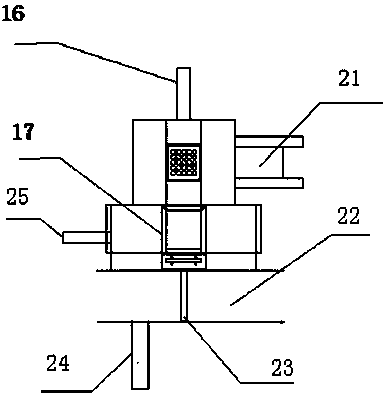

[0026] Such as figure 1 , 2 As shown, an automatic assembly machine for inner and outer cylinders for the production of combined fireworks, including: an inner cylinder template separation mechanism with the inner cylinder template loaded with medicines entering the upper working plane for process separation; The outer cylinder formwork enters the lower working plane to carry out an automatic assembly mechanism for online assembly with the inner cylinder; the upper working plane side of the frame 10 is provided with an inner cylinder formwork entry and exit for the inner cylinder formwork to enter the inner cylinder formwork separation starting station 7 Working mechanism; the inner cylinder formwork separation starting station 7 is provided with an inner cylinder formwork separation mechanism that disengages the inner cylinder formwork from the inner cylinder row pipe 1,

[0027] The one side of the lower working plane of the frame 10 is provided with an outer cylinder formw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com