Waste paper recycling and rolling mechanism of paper cup machine

A technology of paper cup machine and waste paper, which is applied in the directions of winding strips, thin material processing, transportation and packaging, etc., which can solve the problems of increasing equipment costs, achieve the effects of improving the use function, improving the production and working environment, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

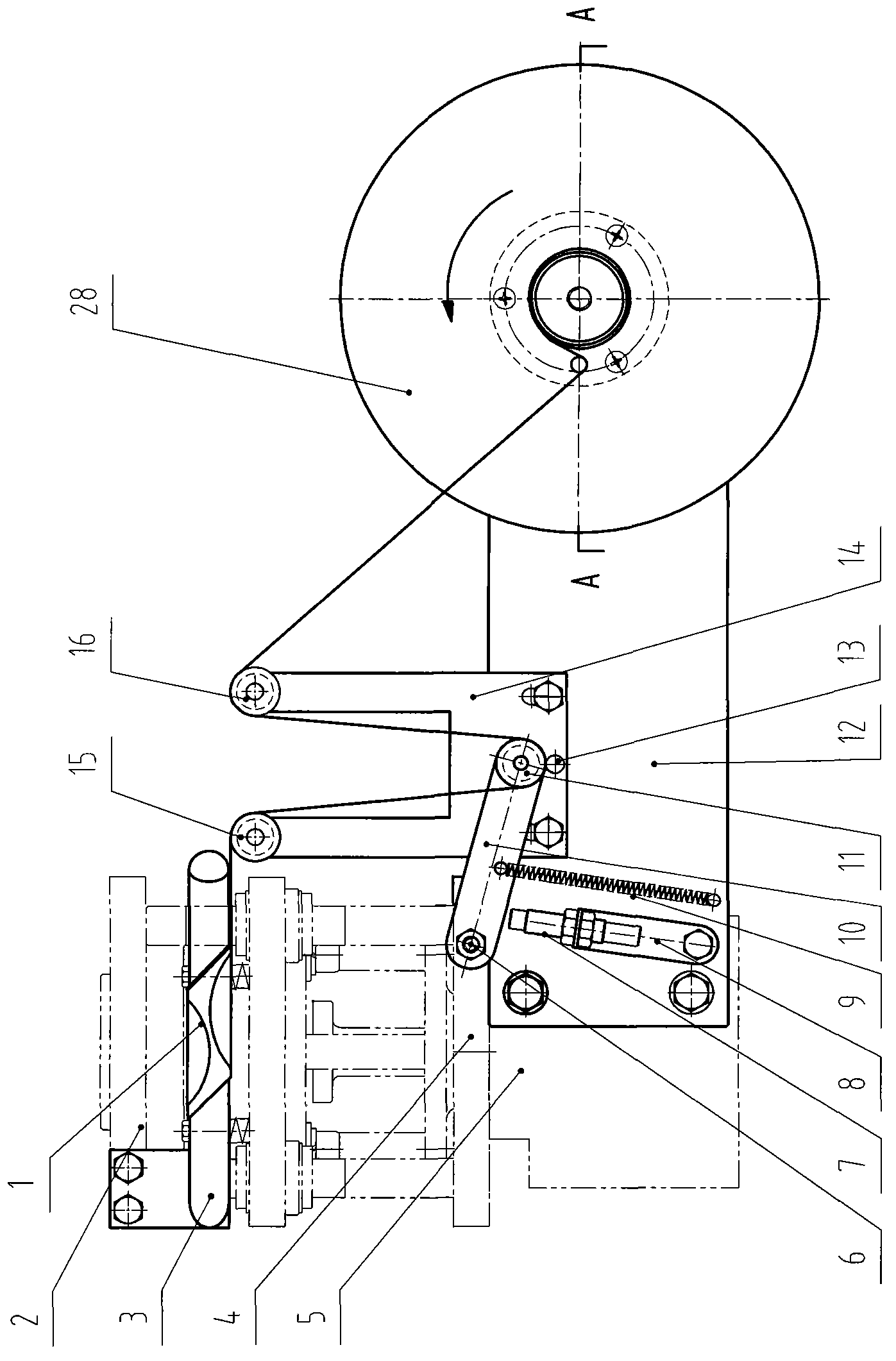

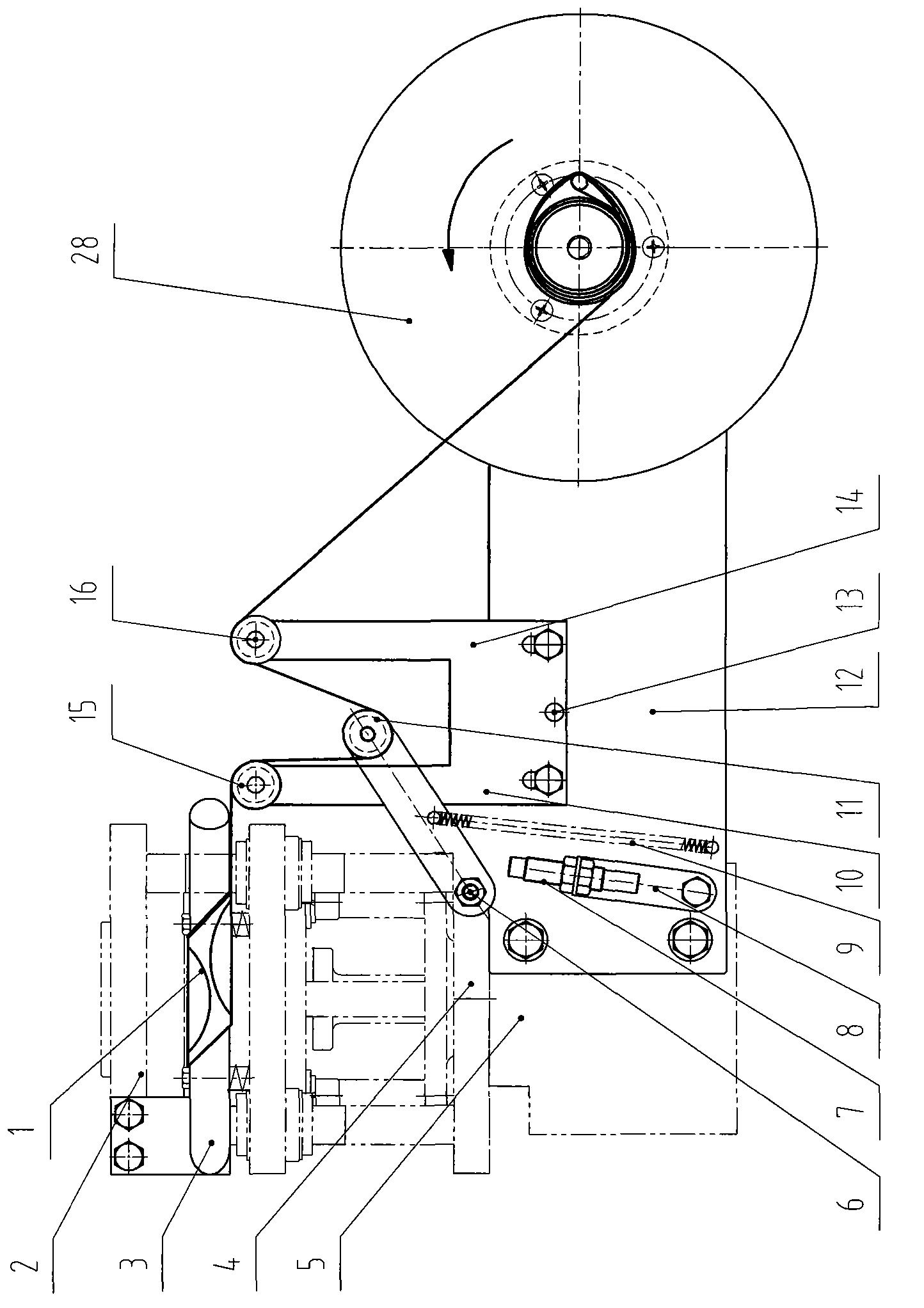

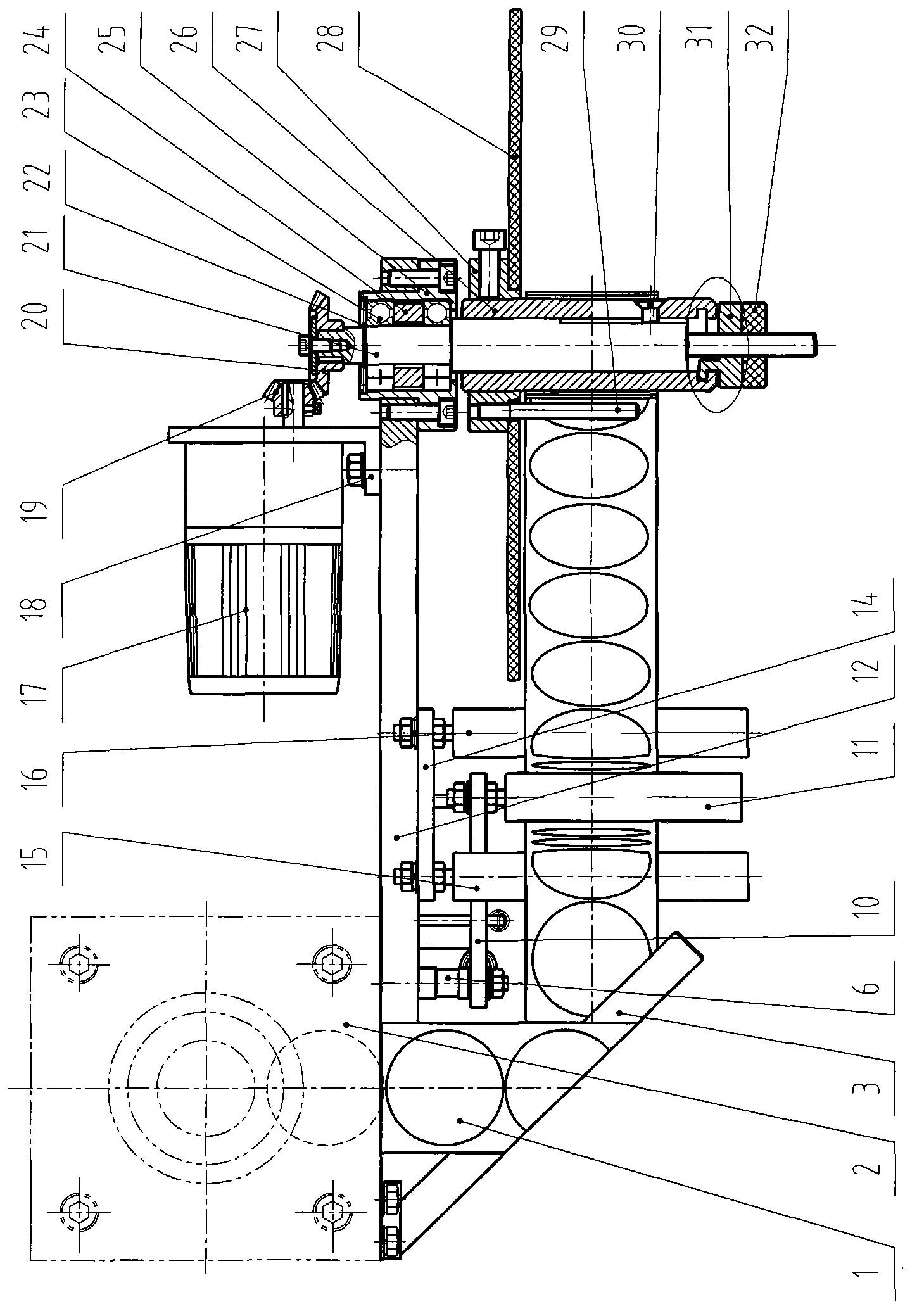

[0014] The present invention will be further described below in conjunction with accompanying drawing embodiment:

[0015] The technical solution adopted in the present invention is: the waste paper rewinding mechanism is composed of a waste paper collecting part and a waste paper rolling part, and the waste paper collecting part is mainly composed of a reversing arm 3, a shaft pin 6, a light eye switch 7, and a switch seat 8 , Extension spring 9, swing arm 10, pressure roller 11, bracket plate 12, gear lever 13, roller seat 14, roller I15, roller II16 and other parts. One end of the reversing arm 3 is fixedly connected to the upper die plate 2 of the cutting mechanism by bolts, the other end of the reversing arm 3 is inclined outward at an angle of about 45°, one end of the swing arm 10 is movably connected with the pivot pin 6, and the inner part of the pivot pin 6 One end is fixedly connected to the bottom plate 4 of the cutting mechanism, the bottom plate is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com