Automatic assembly production method and assembly production line of combination fireworks

A technology for assembling production lines and assembling fireworks, which is applied in the fields of pyrotechnics, offensive equipment, weapon types, etc., and can solve problems such as simple facilities, no guarantee of labor protection for workers, and low added value of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

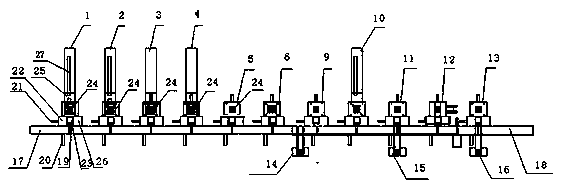

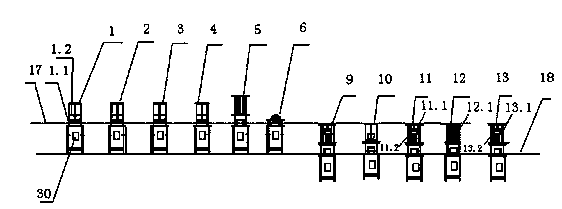

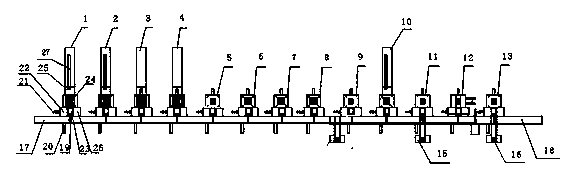

[0140] Such as image 3 As shown, a combined fireworks automatic assembly production method, the inner cylinder tube assembly production process is replaced by: the inner tube tubes without tails are loaded on the inner tube template 18, and then the inner tube tubes are placed on the inner tube template 18 through the upper conveyor belt 17. The cylinder formwork 18 is transported to the inner cylinder pipes for charge, inner cylinder pipes for beads, inner cylinder pipes for rattles, inner cylinder pipes for fixing agent, inner cylinder pipes for Sealing agent, compacting sealing agent, inner cylinder pipe pouring point tail and inner cylinder pipe pouring equipment import are assembled in sequence; or the inner cylinder pipe assembly process is replaced by: inner cylinder charging, sealing agent, The compacting assembly process; or the inner tube row pipe assembly process is replaced by: inner tube charging, beads loading, sealing agent loading, compacting assembly process....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com