Boiler Dust Collector

A dust collector and boiler technology, applied in the field of boiler dust removal devices, can solve the problems of incomplete dust removal, large space occupation, complex structure, etc., and achieve the effects of improving production and working environment, preventing dust explosion, and simple conveying process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

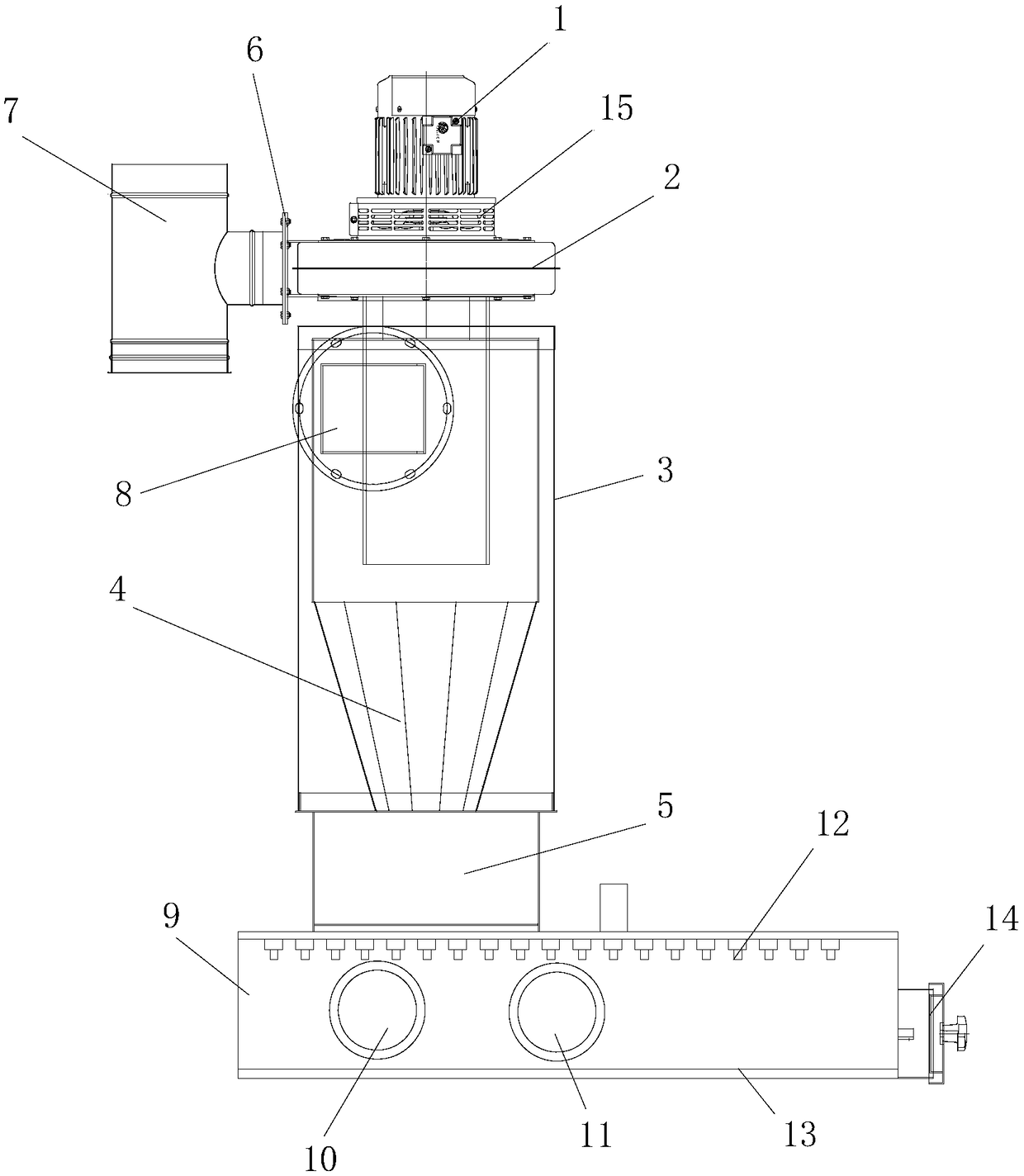

[0008] The specific implementation of the present invention will be described in detail below in conjunction with the drawings and preferred embodiments. Such as figure 1 As shown, a boiler dust collector includes a motor 1, a motor wind box 2, a dust box 3, a tapered cloth bag 4, and a collection box 5. The motor wind box is installed on the upper part of the dust box and the inner The tapered cloth bag is connected. This device uses a unique tapered cloth bag, which is a whole, instead of multiple structures in the prior art. The advantage of this is that when dust falls on the cloth bag, due to the tapered structure, When the motor is working, the dust can automatically fall from the cloth bag to the bottom due to the vibration, thus eliminating the need for a separate beating device in the traditional structure. The output end of the motor is connected with the fan blades arranged in the motor wind box. One side of the motor wind box is connected with the exhaust pipe 7 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com