Boiler slag and dust removing equipment

A dust removal equipment, boiler technology, applied in the direction of lighting and heating equipment, etc., can solve the problems of abnormal and stable operation of the slag pump system, dust affecting the normal operation of the slag removal equipment, slag easily causing dust, etc., to improve equipment and personnel production Improve the working environment, improve the utilization rate and service life of equipment, and facilitate the removal of slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

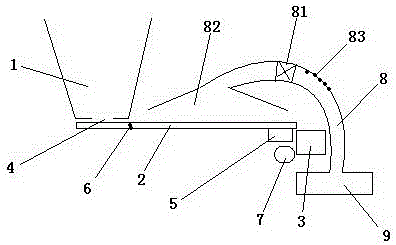

[0011] Such as figure 1 The boiler slag removal and dust removal equipment shown includes a boiler 1, a conveying plate 2 and a slag storage chamber 3, one end of the conveying plate 2 is arranged at the lower part of the slag outlet 4 of the boiler, and a counterweight is arranged at the bottom of the other end of the conveying plate 2 5. A rotating shaft 6 is installed in the middle of the conveying plate, and a high-pressure air device 7 is arranged under the counterweight 5; a dust removal pipe 8 is arranged on the upper part of the conveying board 2, and a one-way valve 81 is arranged on the dust removal pipe 8, and the bottom of the dust removal pipe 8 is One end is connected with dust collection cover 82, is provided with conveyer belt below the dust collection cover, and the other end of conveyer belt is positioned at the top of storage room 9, and storage room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com