Method for centralized collection and sorting treatment of shredded smoke in leaf laying process in threshing and redrying

A technology of leaf threshing, re-baking and shredded tobacco, which is applied in the fields of tobacco treatment, chemical instruments and methods, and separation of solids from solids with airflow, etc., which can solve the problems of proper handling of shredded tobacco, high impurity content of shredded tobacco, and poor purity and other problems to achieve the effect of alleviating the pressure of picking, improving the processing environment and improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

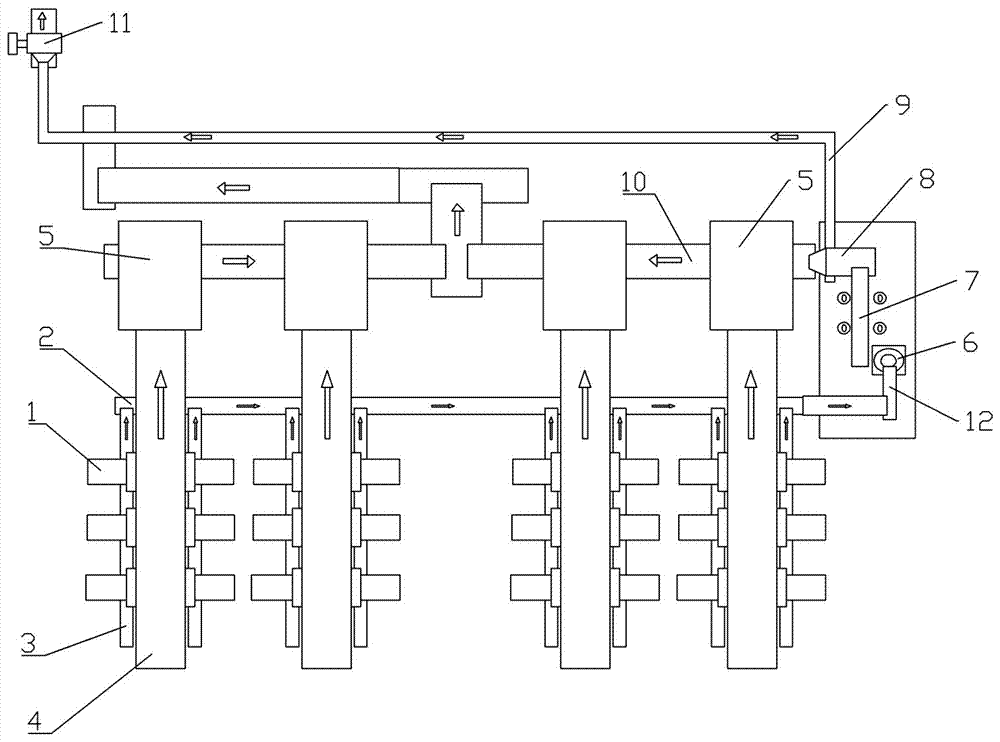

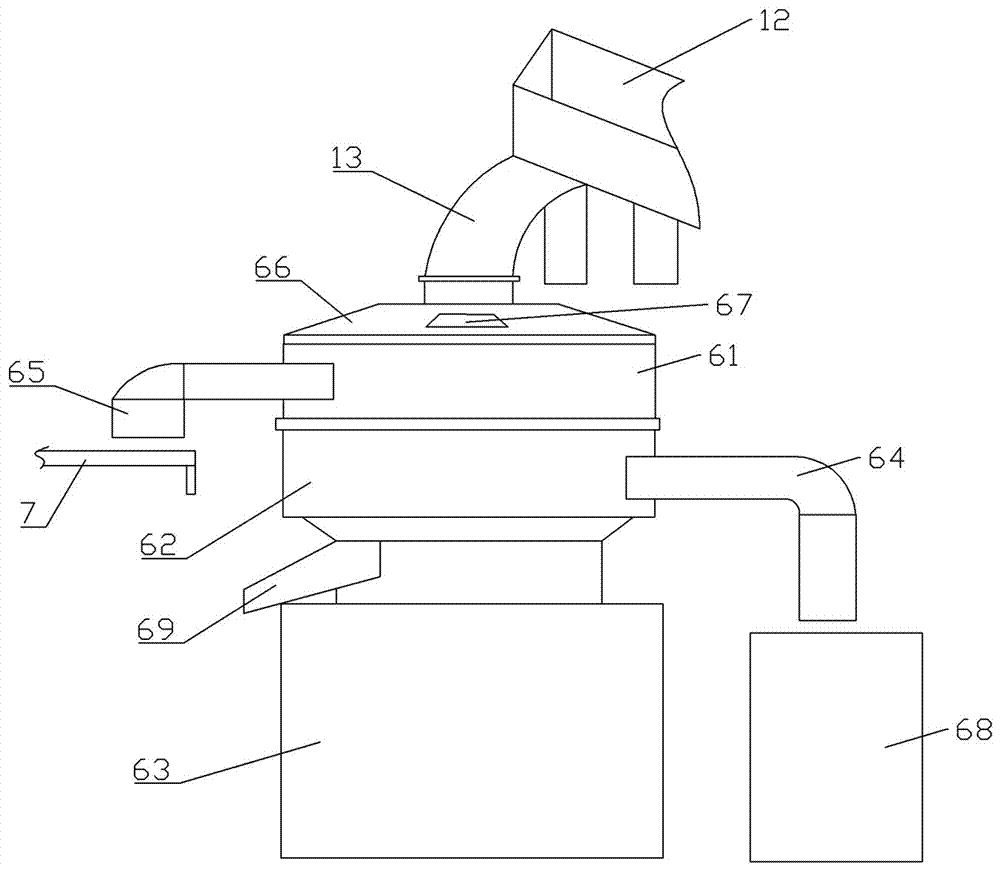

[0024] See attached figure 1 , 2 As shown, the system for centralized collection and classification of shredded smoke in the leaf laying process in leaf threshing and rebaking of the present invention includes a leaf laying station, a shredded smoke collection and separation unit, a slow-speed picking belt and an air delivery pipeline system, and the leaf laying stands are respectively Set on several leaf laying stations, the broken smoke collection and separation unit includes a broken smoke collection conveyor belt, a vibration separation device and an electromagnetic three-stage vibrating screen, the broken smoke collection conveyor belt includes a branch conveyor belt and a main conveyor belt, and one end of the leaf laying platform There are a number of broken smoke collection holes, and the branch conveyor belt is set under the broken smoke collection hole. The main conveyor belt receives the broken smoke collected by each branch conveyor belt, and transports it to the f...

Embodiment 2

[0032] Utilize the system described in embodiment 1 to carry out the method for collecting and sorting the shredded smoke in the leaf laying process in the leaf threshing and rebaking process. The detailed steps of the method are as follows:

[0033] a. First, prepare the raw materials according to the conventional method of threshing and re-baking of tobacco leaves, vacuum moisture regain, and then place the treated tobacco leaves on the leaf laying platform, and the broken tobacco in the tobacco leaves passes through the multiple broken smoke collection holes set on the leaf laying platform , and fall into each branch conveyor belt located below the broken smoke collection hole; normal tobacco leaves are sent to the conveyor belt for debonding, and then sent to the debonding machine in turn according to the conventional method for debonding, drum desanding, once moistening leaves, once Wind separation, manual selection, secondary wind separation, quantitative feeding, seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com