Method for manufacturing high-frequency high-speed data transmission cable

A high-speed data transmission and manufacturing method technology, applied in the direction of cable/conductor manufacturing, cables, insulated cables, etc., can solve the problems of cumbersome process, high difficulty, error-prone, etc., and achieve good shielding effect, simple structure, and convenient welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

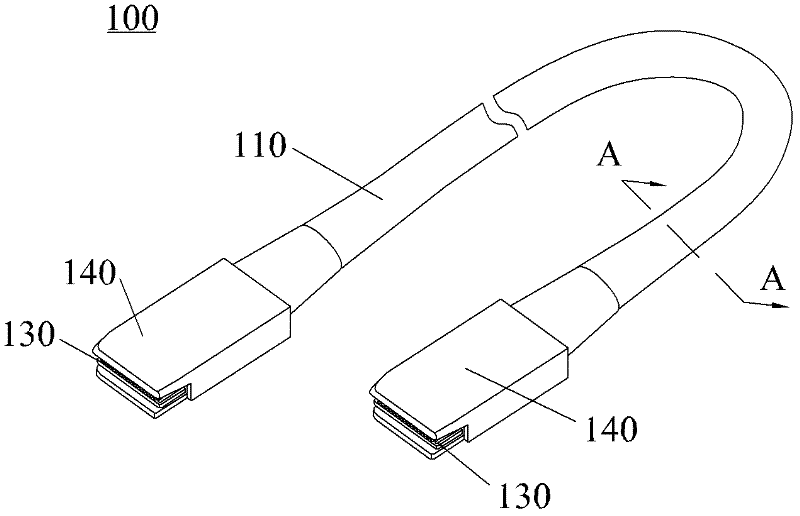

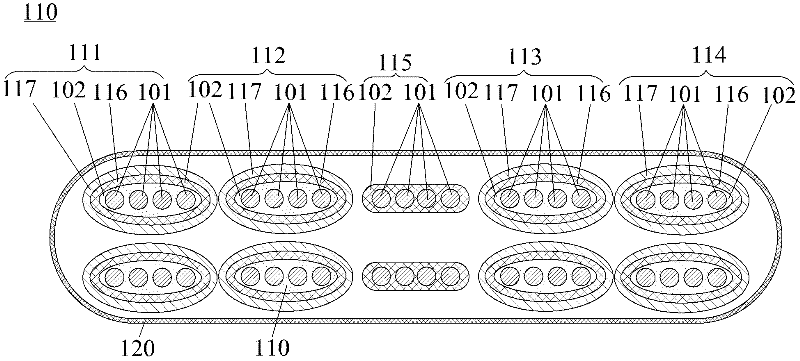

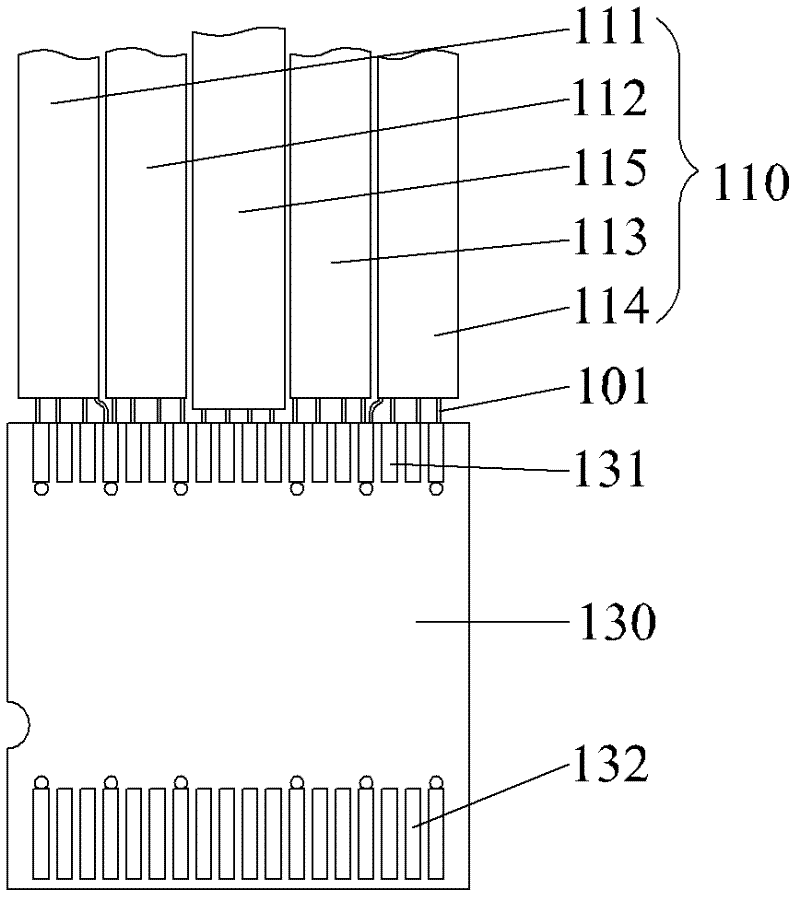

[0021] refer to Figure 4-Figure 5 , the manufacturing method of the high-frequency high-speed data transmission cable of the present invention comprises the following steps: (A1) extruding and forming a layer of insulating layer on the conductor to form a signal line, specifically, extruding and forming a layer of insulating layer on four conductors arranged in a row layer to form a signal line, the signal line is four, and the four signal lines are symmetrically arranged on both sides of the neutral line; (A2) extruding and forming a layer of insulating layer on the conductor to form a zero line, specifically, Extrude and form a layer of insulating layer on four conductors arranged in a row to form a neutral line, and the neutral line is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap