Method for judging etching ending point through valve opening

A technology of etching termination and valve opening, applied in the direction of semiconductor/solid-state device testing/measurement, etc., can solve the problem of high cost and achieve the effect of low cost, stable process and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

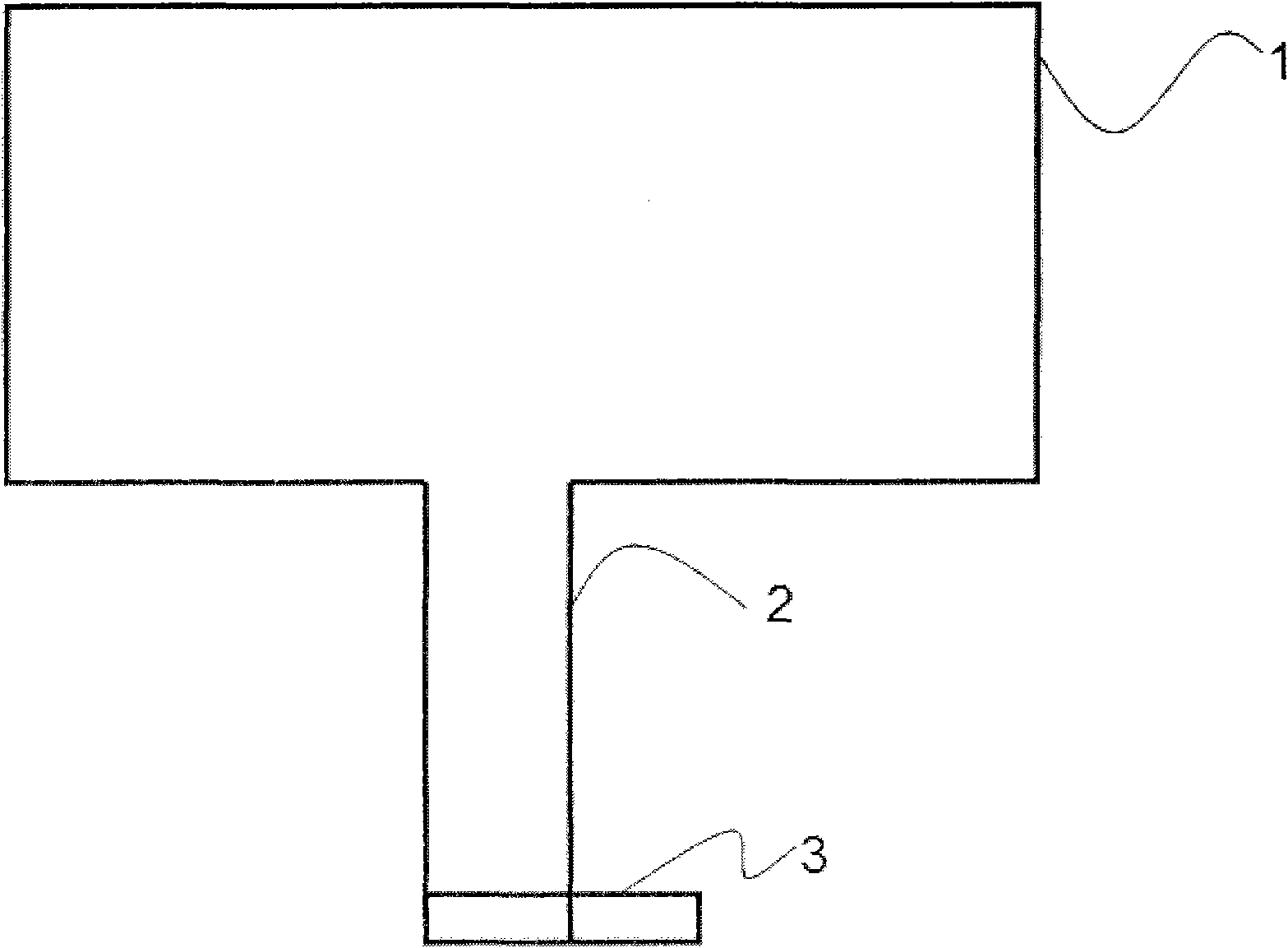

[0024] Such as figure 1 As shown, in the process of etching and cleaning the chamber of the PECVD equipment, the pressure in the chamber 1 remains unchanged, and the method of judging the completion of etching and cleaning is determined by monitoring the opening of the valve 3 on the exhaust pipe 2 .

[0025] In the etching process, the process parameters are as follows:

[0026] Oxygen flow: 1600sccm;

[0027] C 2 f 6 Flow: 1600sccm;

[0028] Pressure inside the chamber: 3 Torr (torr);

[0029] During the etching process, when the opening of the valve changes from 17% to 13%, the etching cleaning is completed.

[0030] In this embodiment, the controller of the valve can monitor the opening degree of the valve.

[0031] After adopting this embodiment to judge that the etching is terminated, the test data are as follows:

[0032] Table 1

[0033] valve opening

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com