Temperature-controllable power battery module group

A battery module pack and battery module technology, which is applied in battery pack components, secondary batteries, battery temperature control, etc., can solve the problems of power battery usage performance and safety impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

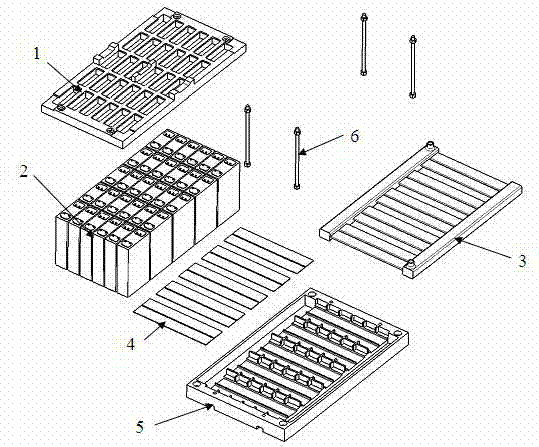

[0025] see figure 1 , the entire battery module group is mainly composed of: an upper cover 1, a battery module group 2, a temperature-controlled fluid cooling device 3, a heat conduction patch 4, a lower frame 5, and connecting bolts 6.

[0026] The specific structures of the main components upper cover 1, temperature-controlled fluid cooling device 3 and lower frame 5 are as follows:

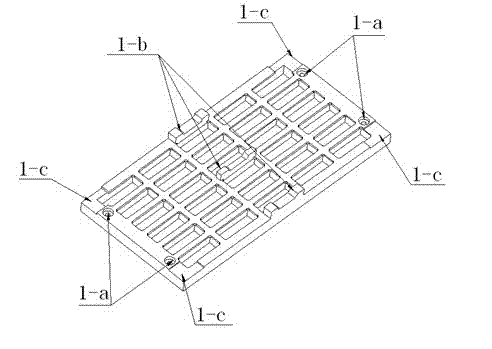

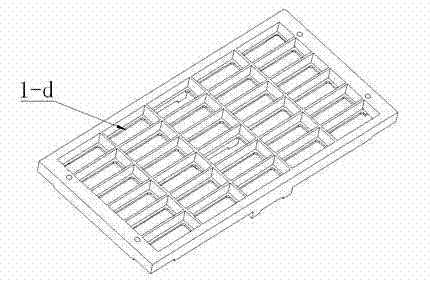

[0027] 1. Top cover (such as figure 2 , image 3 shown):

[0028] The upper cover has a rectangular frame structure, and four countersunk mounting and fixing holes 1-a are evenly distributed at both ends of the frame.

[0029] There are three rectangular bosses 1-b in the middle of the upper cover, and a "U"-shaped groove is opened on the top, which is used for installing bezels or fixing brackets for the battery module.

[0030] The four corners of the upper cover of the battery modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com