Network-based multi-station monitoring integrated matrix display control system

A matrix display and control system technology, applied in image data processing, instruments, character and pattern recognition, etc., can solve the inconvenient access and debugging of the controlled station, increase the workload of maintenance personnel and the probability of error, centralized control system maintenance Inconvenience and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

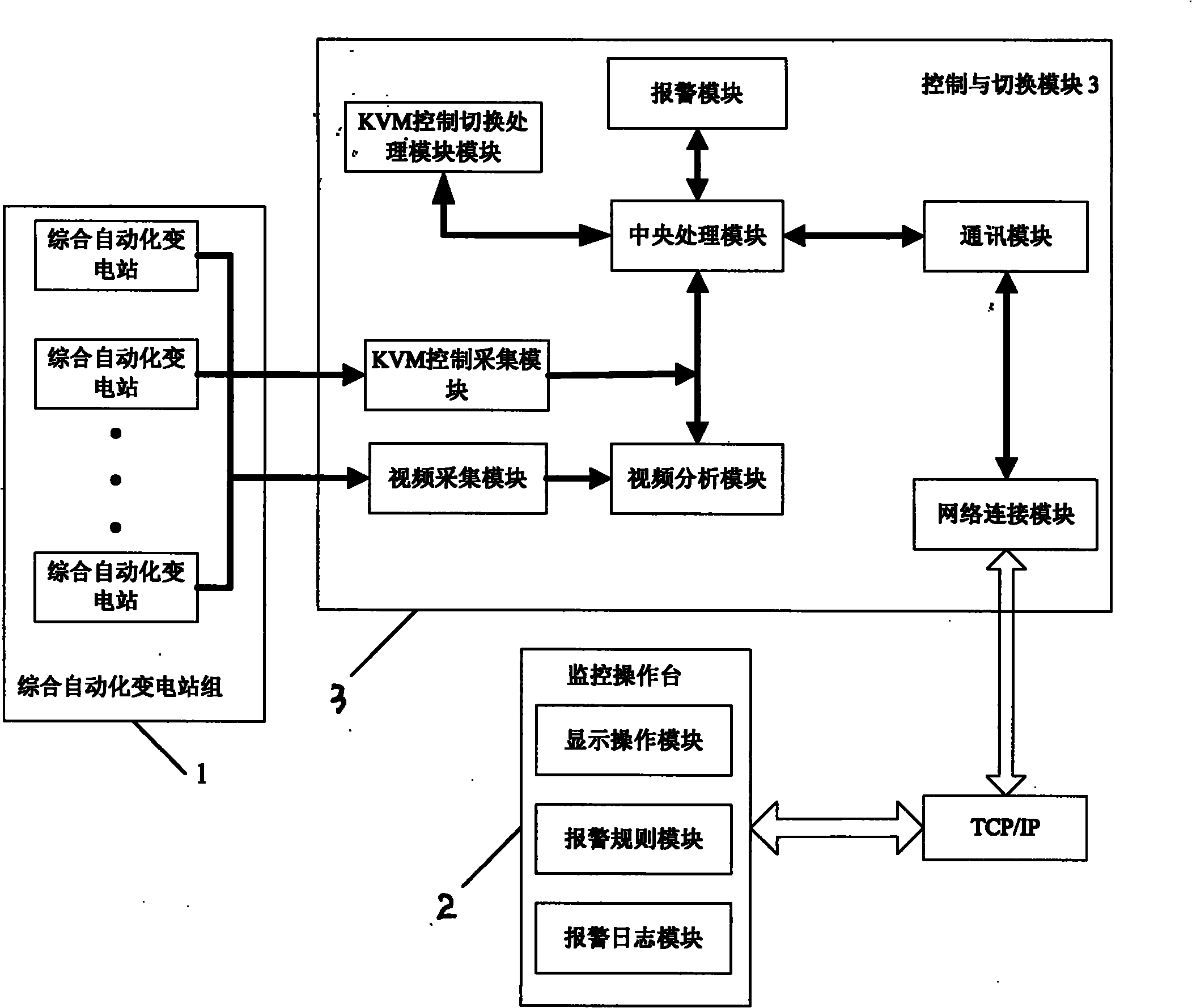

[0028] Such as figure 1 As shown, the present invention includes a comprehensive automated substation group 1 and a monitoring console 2, both of which are connected to a control and switching module 3.

[0029] The following will be explained respectively:

[0030] The integrated automation substation group 1 consists of at least one integrated automation substation. Generally speaking, an integrated automated substation group 1 includes sixteen integrated automated substations.

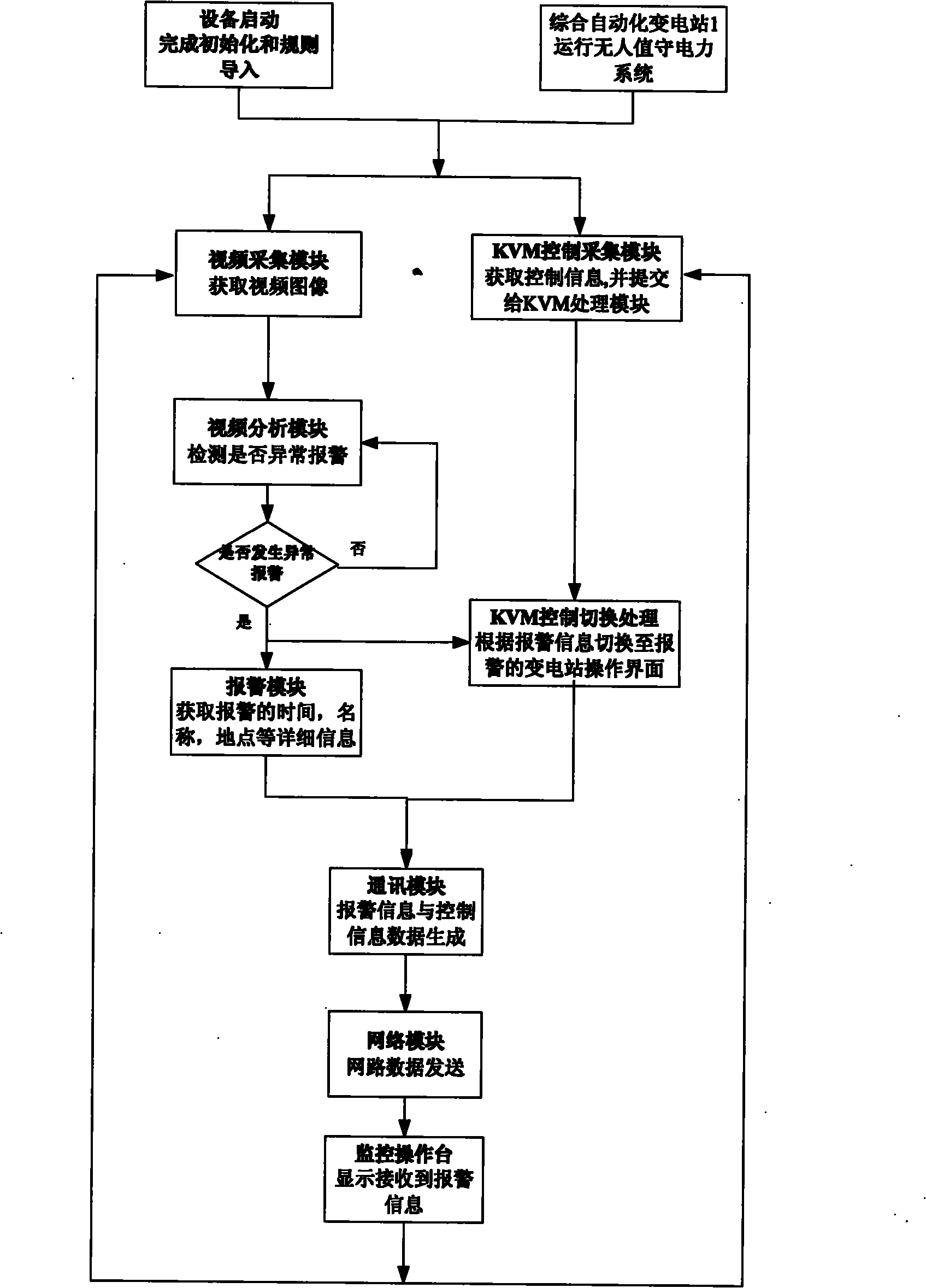

[0031] The control and switching module 3 includes a KVM control acquisition module and a video acquisition module, wherein the KVM control acquisition module acquires the operation control information of each integrated automation substation; the video acquisition module acquires the current picture information of each integrated automation substation, and converts the current picture information After conversion, it is sent to the video analysis module, and the video analysis module obtains the ...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that in this embodiment, the video analysis module obtains the video analysis result through the following steps:

[0049] Step 1, video preprocessing: preprocessing the acquired substation monitoring current picture information,

[0050] The above preprocessing includes removing noise, adjusting frame rate and frame size;

[0051] Step 2, background modeling: establish a reasonable and real background in order to obtain accurate foreground targets;

[0052] Step 3, target tracking: overcome the occlusion problem in target tracking, track multiple targets in the scene, and record their trajectory and direction;

[0053] Step 4, analysis of the movement trajectory: according to the movement trajectory of the target and the set alarm triggering rules, analyze whether the movement trajectory of the target belongs to abnormal activities, and if so, trigger an alarm;

[0054] Step five, target identification: ident...

Embodiment 3

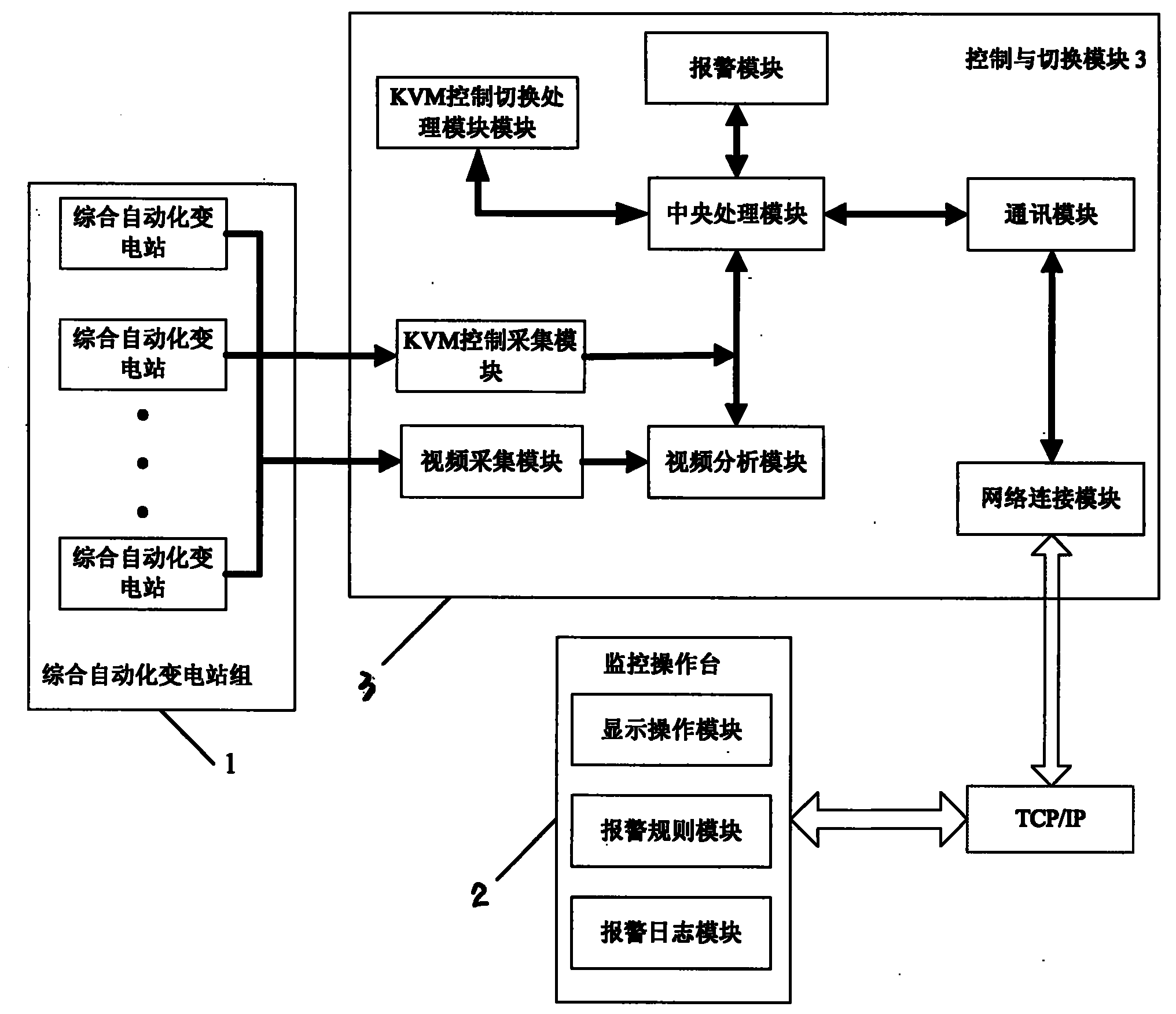

[0057] The difference between this embodiment and the above-mentioned embodiments 1 and 2 is that it is set according to the characteristics of centralized control of multiple integrated automation substations in the centralized control station, that is, each integrated automation substation in the integrated automation substation group 1 is connected to a monitoring console 2-phase connection.

[0058] Generally, multiple integrated automated substations require multiple monitoring consoles, and 16 integrated automated substations require 16 monitoring consoles, and staff also need to monitor and maintain multiple operating consoles in real time. The system can set the specified time to start automatically taking turns to display the monitoring operation information of 16 integrated automatic substations on a monitoring console at the set time interval, so as to achieve the goal of saving costs and reducing the workload of maintenance personnel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com