Dispenser system for placement machine, placement machine and method for dispensing a dispenser mediums on components

A placement machine and dispensing technology, applied in the field of dispensing systems, can solve problems such as difficult to adjust spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

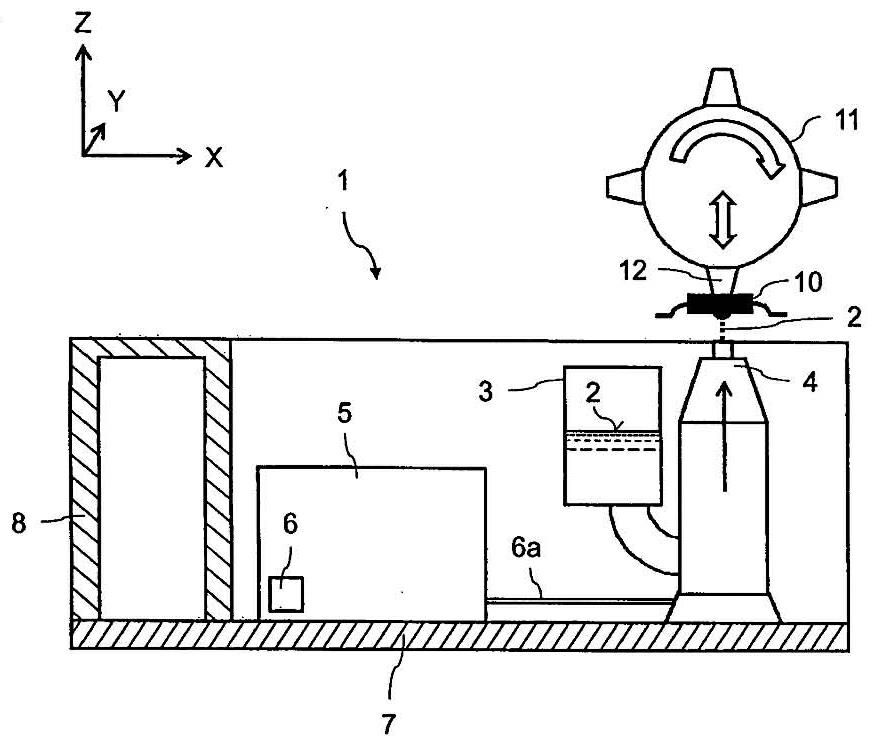

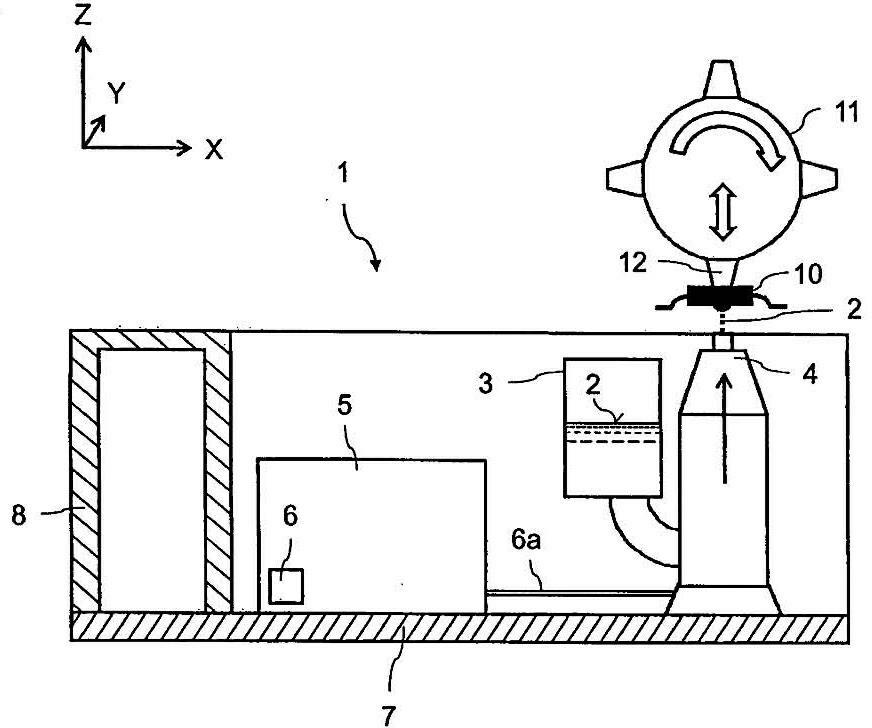

[0041] attached figure 1 A dispensing system is shown that follows the principles of construction established by the present invention. The dispensing system 1 has a storage tank 3 for storing a dispensing medium 2 and has a dispensing nozzle 4 . The advantage of the structure of the dispensing system 1 is that the dispensing system 1 can overcome the gravitational effect of the dispensing medium 2 and spray it out, that is to say, the dispensing medium 2 can be sprayed from bottom to top, so that the The structural component 10 grasped by the placement head 11 of the placement machine can be placed above the dispensing nozzle 4 . This special, even inverted spraying direction of the dispensing medium 2 makes possible a simple and inexpensive dispensing system 1 . The dispensing nozzle 4 of the dispensing system 1 is always fixed, so there is no need to have any device for driving the nozzle. The dispensing system 1 , in particular the dispensing nozzle 4 of the dispensing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com